Jan . 11, 2025 11:11

Back to list

cable cross-linked equipment company

When it comes to selecting the right tensile strength testing equipment, there is no one-size-fits-all solution. The decision to invest in such sophisticated technology requires a deep understanding of both the industry needs and the specific materials involved. Experience, expertise, authoritativeness, and trustworthiness play crucial roles in choosing and operating these machines effectively.

Trustworthiness is built over time, often through a combination of reliability, accuracy of test results, and adherence to ethical standards in reporting. Consumer trust is fostered by the transparency of testing methods and the integrity of data analysis. For companies investing in tensile strength testing, trust in their equipment is essential as it directly affects the quality assurance of their products. When test results are reliable, manufacturers can confidently make claims about their product's performance capabilities, fostering trust with their own customers. Selecting the right tensile strength testing equipment thus involves careful consideration of the equipment’s capabilities, the company’s requirements, and the level of technical support available from the equipment provider. Opt for machines that offer flexibility in testing a wide range of materials and are equipped with user-friendly interfaces that streamline the testing process. Additionally, partnering with companies that offer comprehensive training materials and responsive customer support can make a substantial difference in the smooth integration and operation of this technology within an organization. Investing in high-quality tensile strength testing equipment offers tangible benefits, including an enhanced understanding of material properties, improved product quality, and the ability to innovate. As industries become more competitive, the importance of testing for tensile strength cannot be overstated. It informs not just product development but also risk management, enabling companies to avoid costly failures and reputational damage. In conclusion, for industries reliant on material performance, the choice of tensile strength testing equipment is a strategic investment. It demands consideration of multiple factors including the equipment's precision, the manufacturer's reputation, and the ongoing support they offer. By emphasizing experience, expertise, authoritativeness, and trustworthiness, businesses not only comply with industry standards but also carve a niche in quality assurance, paving the way for innovation and growth.

Trustworthiness is built over time, often through a combination of reliability, accuracy of test results, and adherence to ethical standards in reporting. Consumer trust is fostered by the transparency of testing methods and the integrity of data analysis. For companies investing in tensile strength testing, trust in their equipment is essential as it directly affects the quality assurance of their products. When test results are reliable, manufacturers can confidently make claims about their product's performance capabilities, fostering trust with their own customers. Selecting the right tensile strength testing equipment thus involves careful consideration of the equipment’s capabilities, the company’s requirements, and the level of technical support available from the equipment provider. Opt for machines that offer flexibility in testing a wide range of materials and are equipped with user-friendly interfaces that streamline the testing process. Additionally, partnering with companies that offer comprehensive training materials and responsive customer support can make a substantial difference in the smooth integration and operation of this technology within an organization. Investing in high-quality tensile strength testing equipment offers tangible benefits, including an enhanced understanding of material properties, improved product quality, and the ability to innovate. As industries become more competitive, the importance of testing for tensile strength cannot be overstated. It informs not just product development but also risk management, enabling companies to avoid costly failures and reputational damage. In conclusion, for industries reliant on material performance, the choice of tensile strength testing equipment is a strategic investment. It demands consideration of multiple factors including the equipment's precision, the manufacturer's reputation, and the ongoing support they offer. By emphasizing experience, expertise, authoritativeness, and trustworthiness, businesses not only comply with industry standards but also carve a niche in quality assurance, paving the way for innovation and growth.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

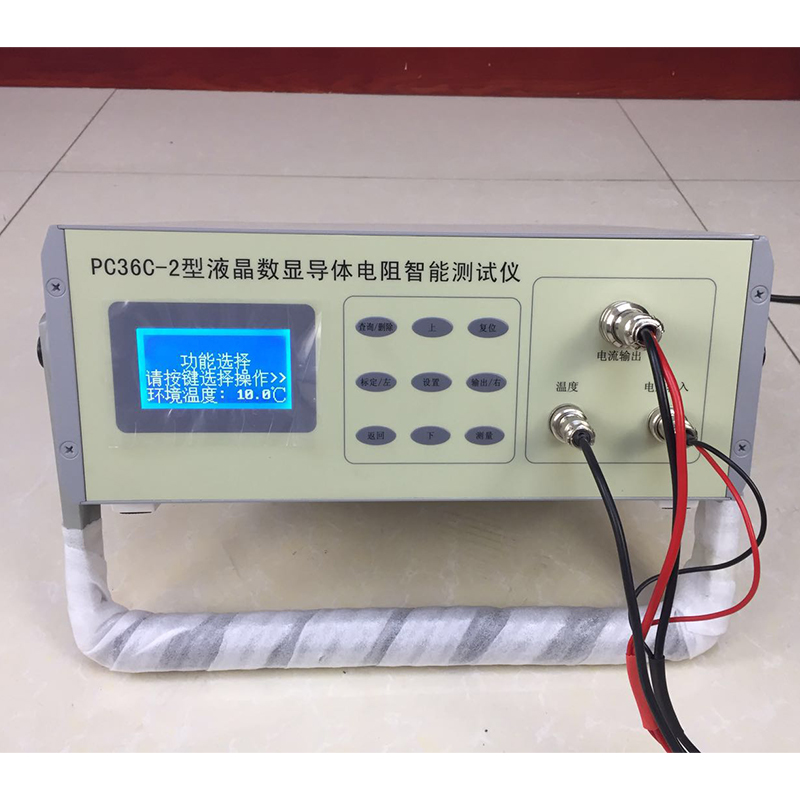

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy