Cable Vertical Burning Test Equipment Manufacturer for Safety Compliance Testing

An Insight into Cable Vertical Burning Test Machines Importance and Manufacturing

In the world of electrical engineering and safety compliance, the testing apparatus known as the cable vertical burning test machine stands as a crucial tool in evaluating the flammability of various types of cables

. This testing device is essential for manufacturers and quality assurance organizations aiming to meet safety standards that ensure consumer protection and regulatory compliance.Cable vertical burning test machines are designed to determine how different cables react when exposed to a flame under specific conditions. The significance of these tests cannot be overstated, as cables are vital components in numerous applications, ranging from residential wiring to complex telecommunications systems. Any failure in the material quality could lead to catastrophic failures, including electrical fires that pose risks to life and property.

The primary function of a cable vertical burning test machine is to assess the flame propagation along the cable when it is subjected to a vertical flame source. The testing process typically involves fixing the cable vertically in a controlled environment and then applying a flame to its lower end for a specified duration. The rate of burning, the length of the flame propagation, and the time taken for the flame to extinguish are carefully monitored and recorded. The data obtained from these tests provides manufacturers with insights into the fire safety performance of their products.

These tests are not only vital for compliance with national and international safety standards but also serve as a benchmark for product quality. Many countries have stringent regulations governing the flammability of cables, such as the UL 94 standard in the United States and the IEC 60332 standard internationally. Industries that fail to pass these tests may face product recalls, liability issues, or damage to their reputation, making the choice of a reliable testing apparatus essential.

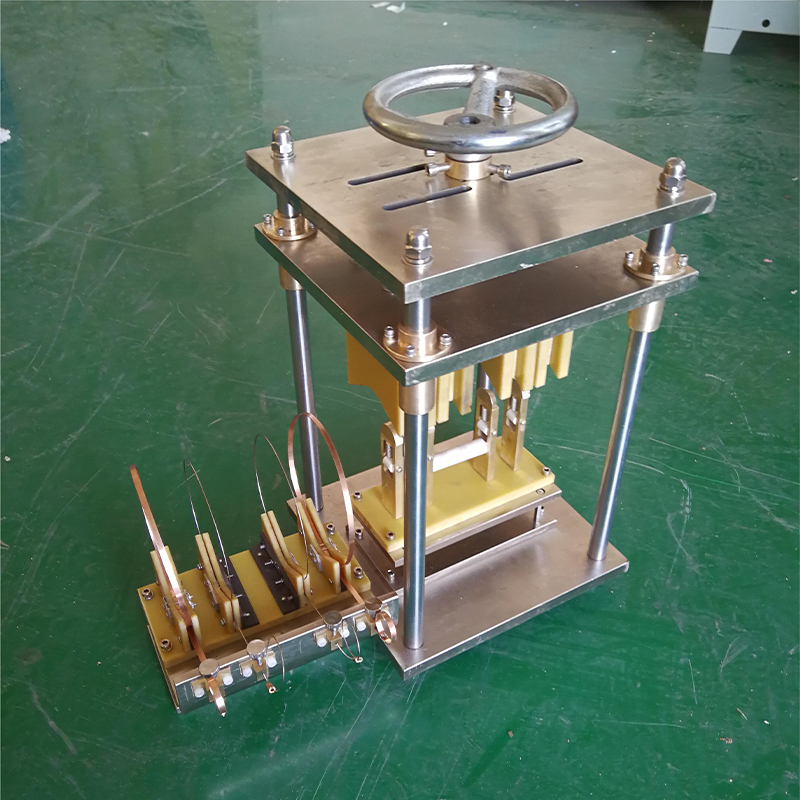

cable vertical burning test machine factory

When it comes to the manufacturing of cable vertical burning test machines, precision and durability are paramount. Manufacturers of these machines focus on creating robust devices that can withstand frequent use and rigorous testing conditions. Typically, these machines are constructed from high-quality materials that are resistant to heat and corrosion. Advanced features such as automatic data recording, user-friendly interfaces, and integration with computer systems for reporting are becoming standard in modern designs.

Moreover, as technology evolves, so does the complexity of cable materials and their applications. Manufacturers are constantly innovating, incorporating new materials such as halogen-free and low-smoke compounds that pose different challenges in fire safety. In this context, cable vertical burning test machines must be adaptable and equipped to handle a wide array of testing scenarios, ensuring that they remain relevant as materials evolve.

In addition, the international market for these machines is growing steadily, spurred by the increasing awareness of fire safety regulations and standards. Manufacturers are now tasked not only with producing machines but also with providing comprehensive support that includes training users on proper testing methods, maintenance of equipment, and interpretation of results.

In conclusion, cable vertical burning test machines play a pivotal role in ensuring the safety and reliability of electrical cables. As cable manufacturers strive to meet ever-evolving safety standards, the importance of reliable testing methods cannot be overlooked. The collaboration between designers, manufacturers, and regulatory bodies will continue to be crucial in enhancing fire safety and protecting lives while enabling the advancement of technology. The ongoing progress in this field promises a future where cables can be designed not only for performance but also for maximum safety.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy