conductor resistance measurement machine factory

Conductor Resistance Measurement Machine A Key Tool in Electrical Engineering

In the realm of electrical engineering, ensuring the quality and reliability of electrical conductors is paramount. One of the most critical parameters in this assessment is the resistance of the conductor. It directly influences the efficiency and performance of electrical systems. To accurately measure this resistance, engineers rely on specialized equipment known as conductor resistance measurement machines. This article explores the significance of these machines, their operational principles, and their applications in various industries.

Understanding Conductor Resistance

Conductor resistance is the opposition a material offers to the flow of electric current. It is influenced by several factors, including the material's intrinsic properties, temperature, and physical dimensions. For conductive materials like copper and aluminum, low resistance is desired to minimize energy losses during electricity transmission. Understanding and measuring this resistance is essential for engineers to ensure that the conductors meet industry standards and specifications.

The Function of Conductor Resistance Measurement Machines

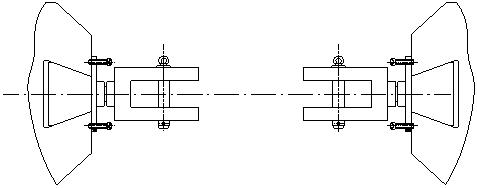

Conductor resistance measurement machines are designed to accurately measure the resistance of electrical conductors, such as wires, cables, and other conductive components. These machines assess the DC (direct current) resistance of conductors, which is a crucial parameter for evaluating their performance. By providing precise measurements, these machines help engineers determine whether a conductor can safely carry the expected current load without overheating or suffering damage.

Operational Principles

The operation of a conductor resistance measurement machine hinges on Ohm's Law, where resistance (R) is defined as the ratio of voltage (V) to current (I) \( R = \frac{V}{I} \). These machines typically employ a constant current source to inject a known current into the conductor. The resulting voltage drop across the conductor is measured, allowing the machine to calculate the resistance accurately.

Modern machines utilize advanced technology, including digital displays and microprocessor-based controls, to enhance measurement accuracy and ease of use

. Some models even incorporate automated features, data logging capabilities, and connectivity options for integration with computer systems, enabling seamless data analysis and reporting.conductor resistance measurement machine factory

Applications in Various Industries

Conductor resistance measurement machines find applications across numerous industries. In electrical utilities, they are vital for testing power lines and substations to ensure reliable electricity distribution. In manufacturing, they assess the quality of wires and cables before they are integrated into products. Furthermore, in the automotive sector, these machines are employed to verify the integrity of electrical components, ensuring safe and efficient vehicle operation.

Another critical application of these machines is within the realm of renewable energy. As the demand for sustainable energy sources grows, the reliability of conductors used in solar panels and wind turbines becomes increasingly important. Conducting resistance tests on these systems helps to maintain efficiency and optimize performance, ultimately contributing to a more sustainable future.

Choosing the Right Equipment

When selecting a conductor resistance measurement machine, several factors must be considered. The accuracy and range of the equipment, ease of use, portability, and data management capabilities are all essential criteria. A good machine should not only deliver precise measurements but also be user-friendly, allowing engineers and technicians to operate it with ease, even in field conditions.

Moreover, manufacturers should be evaluated based on their reputation, customer support, and the availability of calibration services. Calibration is crucial for maintaining measurement accuracy over time, ensuring that the equipment remains reliable throughout its service life.

Conclusion

Conductor resistance measurement machines are indispensable tools in the toolkit of electrical engineers, ensuring the safety and efficiency of electrical systems globally. By facilitating accurate resistance measurements, these machines contribute to the quality and reliability of conductors used in various applications, from power plants to electric vehicles. As technology continues to advance, the evolution of these machines will further enhance their accuracy and functionality, supporting the ongoing development of electrical engineering and the pursuit of innovative, sustainable energy solutions.

-

DQ-F Superfine Wire Conductor Resistance Fixture: High-Precision Testing

NewsAug.30,2025

-

ZC36 High Insulation Resistance: Reliable & Safe Performance

NewsAug.29,2025

-

CX-100 Manual Hydraulic Core Punching Machine - Efficient & Reliable

NewsAug.28,2025

-

Reliable Performance Testing with Advanced Aging Chamber Solutions

NewsAug.23,2025

-

Advancing Precision with Profile Projector Technology

NewsAug.23,2025

-

UV-LED Ultraviolet Crosslinking Technology: Innovation and Prospects

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy