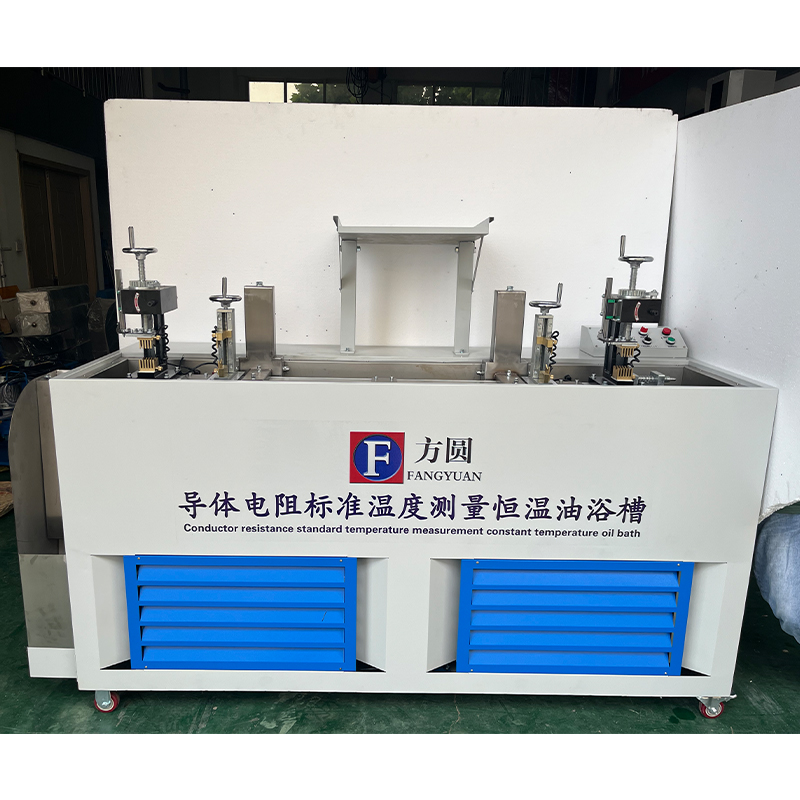

custom thermal stability tester

Custom Thermal Stability Tester Ensuring Quality and Safety in Material Testing

In today's rapidly advancing technological landscape, the need for robust testing solutions that ensure the quality and safety of materials is more crucial than ever. One significant aspect of this is thermal stability, which refers to the ability of a substance to maintain its physical and chemical properties under varying temperature conditions. The custom thermal stability tester has emerged as an essential tool for researchers and manufacturers alike, providing accurate and reliable data that can help in the development and quality assurance of new materials.

Understanding Thermal Stability

Thermal stability plays a vital role in a wide range of industries, including polymers, pharmaceuticals, food, and electronics. Materials that exhibit poor thermal stability can undergo degradation, resulting in undesirable changes such as loss of strength, brittleness, discoloration, or even toxic byproducts. Thus, assessing a material's thermal stability becomes paramount, especially when these materials are subjected to extreme conditions during their lifecycle.

The Role of Custom Thermal Stability Testers

Custom thermal stability testers are specifically designed to meet the unique needs of different applications. Unlike standard testing equipment, custom solutions offer flexibility in terms of design, functionality, and measurement capabilities. These testers can be tailored to accommodate various sample sizes, shapes, and testing environments, ensuring that they provide the most relevant and accurate results for the intended application.

One of the core features of a custom thermal stability tester is its ability to simulate real-world conditions that materials may face during processing and usage. This can include high temperatures, fluctuating thermal cycles, and pressure variations, which are critical for understanding how materials behave under stress. By providing a controlled environment for testing, these instruments enable researchers to conduct thorough evaluations that can lead to improvements in material formulations and processing techniques.

Key Features and Benefits

1. Precise Temperature Control Custom thermal stability testers are equipped with advanced control systems that allow for precise temperature management. This ensures that materials are tested under consistent and repeatable conditions, yielding reliable and reproducible results.

custom thermal stability tester

2. Modular Design These testers can be designed with modular components, allowing users to add or modify features based on their specific testing requirements. This adaptability is particularly beneficial for organizations that conduct a variety of material assessments.

3. Data Acquisition and Analysis Modern custom thermal stability testers often come with sophisticated data acquisition systems. These systems can collect extensive data during the testing process, which can then be analyzed to gain insights into material behavior and performance.

4. User-friendly Interface Many custom testers are designed with user-friendly interfaces, enabling operators to set parameters easily and monitor tests in real-time. This reduces the likelihood of human error and facilitates efficient workflows.

5. Compliance with Standards Custom thermal stability testers can be designed to comply with industry standards and regulations, ensuring that results are accepted in regulatory submissions or quality control processes.

Applications in Various Industries

Custom thermal stability testers find applications across numerous fields. In the pharmaceutical industry, for instance, they are crucial for assessing the stability of drugs under various temperature conditions, thereby ensuring safety and efficacy. In the aerospace and automotive sectors, these testers can help evaluate composites and alloys that need to withstand extreme heat and stress. Moreover, the electronics industry relies on thermal stability testing to ensure that components do not fail when exposed to high temperatures during operation.

Conclusion

In conclusion, the development of custom thermal stability testers represents a significant advancement in material testing technology. By providing tailored solutions that meet the diverse needs of various industries, these testers play a critical role in ensuring product quality and safety. As research and development continue to evolve, the demand for such specialized testing equipment will undoubtedly grow, paving the way for innovations that enhance the performance and longevity of materials used in countless applications. Ultimately, the integration of custom thermal stability testers into testing protocols will contribute to the advancement of materials science and engineering, driving progress across a plethora of sectors.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy