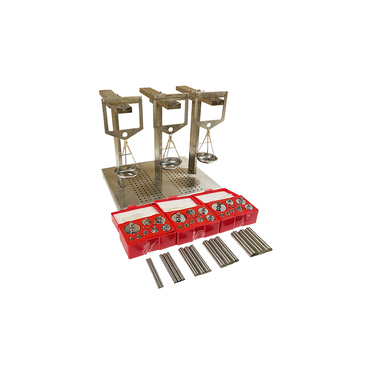

china tensile tests machine

Understanding Tensile Testing Machines in China

Tensile testing is a fundamental procedure in material science and engineering that assesses the mechanical properties of materials, particularly their strength and ductility. In the context of China, the development and utilization of tensile testing machines have expanded significantly, driven by rapid industrial growth and the increasing demand for quality assurance across various sectors, including construction, manufacturing, and aerospace.

A tensile testing machine, or tensile tester, is designed to measure the response of materials when subjected to tension until failure. The primary outputs of a tensile test are the tensile strength, elongation, and modulus of elasticity of the material, which are crucial for determining its suitability for specific applications.

Importance of Tensile Testing in China

With China's status as a global manufacturing hub, the demand for tensile testing machines has surged. Industries such as steel production, automotive, electronics, and textiles rely heavily on these machines to ensure the materials used meet the required standards for durability and safety. Tensile testing not only helps in material selection but also plays a critical role in research and development, enabling engineers to innovate new materials and products.

The significance of tensile testing extends to quality control, where manufacturers must comply with international standards such as ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization). Compliance ensures that products can withstand operational loads and stresses, thereby enhancing safety and reliability.

Technological Advancements in Tensile Testing Machines

China's tensile testing machines have evolved considerably due to advancements in technology. Modern testers are equipped with computer-controlled systems that provide precise measurements and analytics. These systems often feature user-friendly interfaces and can integrate with software to facilitate data collection, analysis, and reporting.

china tensile tests machine

The latest machines utilize advanced sensors and measurement technologies to enhance accuracy. For instance, digital image correlation (DIC) technology allows for real-time monitoring of deformation, providing more detailed insights into material behavior during testing. Furthermore, servo-controlled systems enable smoother and more consistent load application, which is crucial for accurately capturing the material's response.

In recent years, there has been a growing emphasis on automation and smart manufacturing in China. Tensile testing machines are increasingly integrated into automated testing systems, which can significantly improve efficiency by reducing manual intervention and the potential for human error. This shift aligns with China's broader industrial strategy to enhance productivity and competitiveness in the global market.

Challenges and Future Prospects

Despite the advancements, challenges remain in the field of tensile testing in China. The need for skilled technicians who can operate and maintain sophisticated testing machines is critical. As industries adopt more complex materials, such as composites and advanced alloys, the need for specialized testing methods and equipment also increases.

Furthermore, as environmental regulations tighten, manufacturers are under pressure to not only produce high-quality materials but also to ensure that testing methods are environmentally sustainable. Innovations in testing methods that require less material consumption or generate less waste are becoming more relevant.

Looking ahead, the future of tensile testing machines in China appears promising. As technology continues to advance, we can expect to see even more precise, efficient, and environmentally friendly testing solutions. The growing trend towards digitization and the Internet of Things (IoT) will likely lead to more interconnected testing environments, enhancing data collection and enabling predictive analytics.

In conclusion, tensile testing machines play a vital role in ensuring the integrity and performance of materials in China’s burgeoning industries. With ongoing advancements and a focus on quality and safety, these machines will continue to be instrumental in supporting China's commitment to high manufacturing standards.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy