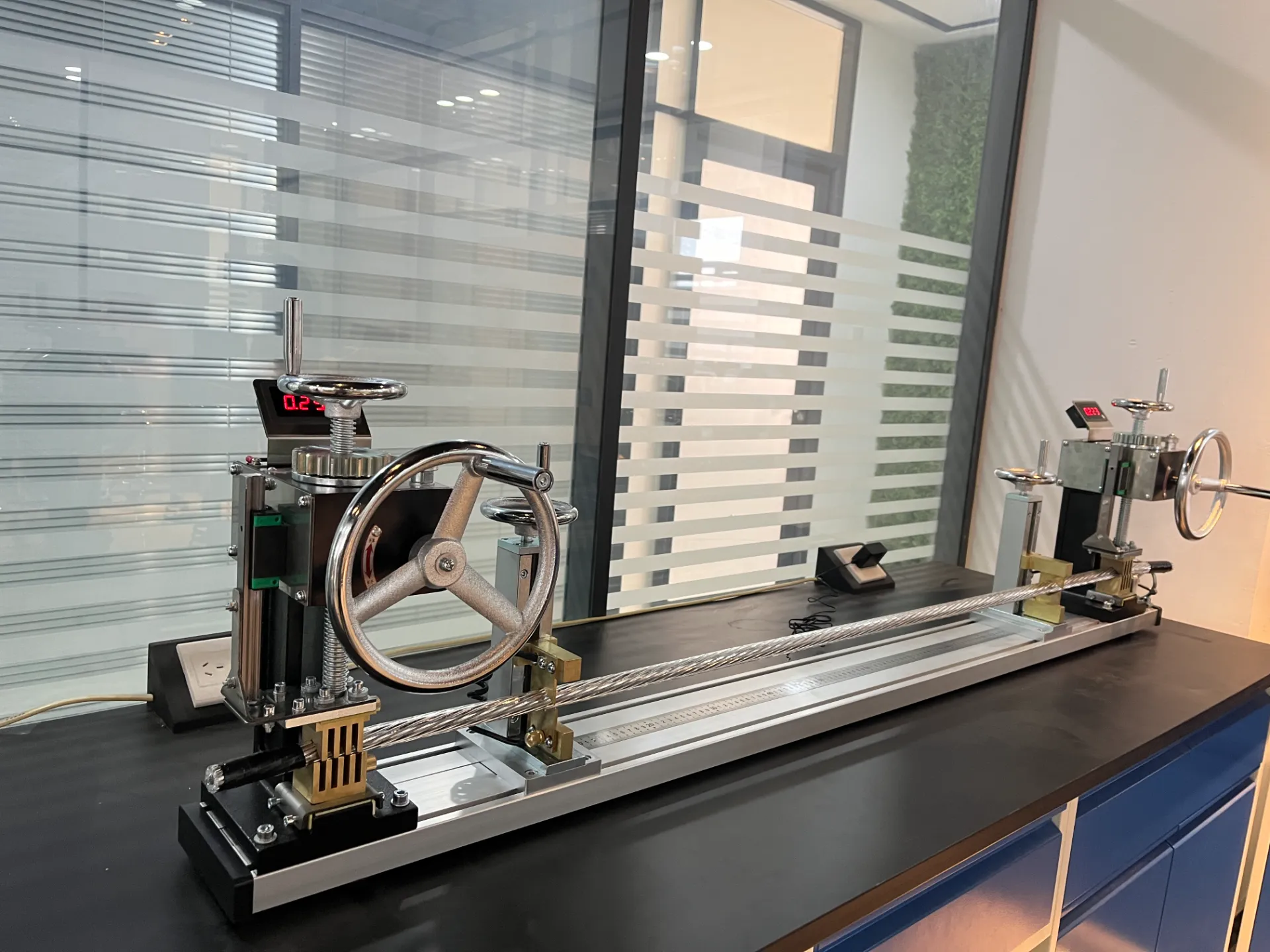

High-Precision Cable Torsion Testing Machine – Reliable Performance & Durable Design

Do you know that 38% of reported cable failures in power and data systems are due to undetected torsion damage? The stakes couldn’t be higher. For aerospace, automotive, and telecom companies, a single undetected cable flaw can cost millions. A world powered by precision demands nothing but the best in cable durability testing. This is where the cable torsion testing machine

steps in, scientifically engineered to meet today's reliability standards.

(cable torsion testing machine)

Delivering Precision: Technical Advantages of Modern Cable Torsion Testing Machines

Modern cable torsion testing machines are not just metal and motors. They are intelligent systems, blending high-tech sensors and intuitive software interfaces. Why does this matter? Tight tolerances. Consistent performance. Reliable data. Industry surveys show that companies using advanced torsion machines report a 60% drop in product recalls. That’s real ROI.

Let’s break down the technical edge:

- Automatic, programmable torsion cycles

- Digital torque and angle feedback with ±0.5% accuracy

- Test speed: 5–90 rpm with step-less regulation

- Sample length: 200–1000 mm, adaptable fixture systems

- Comprehensive safety shields and overload protection

- Windows-based control software, full test data export

Here’s a quick product comparison sample for clarity:

| Model | Torque Range (Nm) | Sample Length (mm) | Interface | Cycle Setting |

|---|---|---|---|---|

| ProTorsion 6000 | 0–50 | 200–1000 | Touchscreen PLC | Yes |

| MegaTwist X | 0–120 | 500–1300 | Windows PC | Yes |

Which one suits your cables? If you can imagine it, these machines can test it.

Choosing the Right Partner: Comparing Cable Torsion Testing Machine Companies

There’s no shortage of cable torsion testing machine companies promising the sky. But are all manufacturers the same? Not even close. Key differences come down to:

- Facility Certifications (ISO 9001, CE, UL)

- Service and calibration support

- Software capabilities and future upgrades

- Export experience and documentation

- Warranty duration and parts availability

Did you know that 75% of exporters rely on third-party test validation? Don’t settle for demo videos only. Ask the manufacturer for real-world case studies and customer references. Request an online demo. See the QA process firsthand.

Top cable torsion testing machine exporters set themselves apart by transparent pricing, fast logistics, and global after-sales support. Looking for a seamless procurement experience? Choose partners who value your timelines and standards—always.

Customized Solutions: Tailored Cable Torsion Testing Machines for Every Industry

Your products are unique. Your testing process should be, too. Off-the-shelf doesn’t always cut it. That’s why elite cable torsion testing machine manufacturers offer extensive customization:

- Adjustable jaws to fit odd diameters

- Extended torque ranges for reinforced cables

- Specialized test sequences (reverse, pulsed, or combined stress)

- Automated sample loaders for high-volume labs

- Hybrid models to combine tension, flex, and torsion testing

Why customize? Because you know your failure scenarios best. Maybe you need 300,000 cycles per test—no problem. Perhaps your cables are exposed to -40°F conditions. Just specify, and top manufacturers will deliver purpose-built solutions, every time.

Here’s a quick look at a sample specification table for custom builds:

| Parameter | Standard | Custom Option |

|---|---|---|

| Torque Range (Nm) | 0–60 | 0–300 |

| Sample Temp (°F) | 41–104 | -40–212 |

| Cycle Count | Up to 50,000 | Up to 500,000 |

| Data Interfaces | USB | Ethernet/WiFi |

Are you ready for testing that adapts to you—not the other way around?

Real-World Application Cases: How Cable Torsion Testing Saves Millions

Numbers tell the truth. Take the story of an automotive wiring OEM: Before upgrading to an advanced cable torsion testing machine, they faced frequent recalls due to undiscovered micro-cracks. After installation, cable rejection rate dropped by 82% within 8 months.

Or the telecom company expanding 5G infrastructure. Their older testing setup missed subtle insulation failures caused by torsion. After switching to a next-gen system, they documented a 70% uptick in cable lifespan. Downtime costs? Plummeted.

Aerospace contractors, often working with critical safety cables, rely on custom machine settings to meet FAA and NASA guidelines. Using high-precision cable torsion testing machines ensures every unit delivered exceeds international standards. Who benefits? You do. Your brand. Your customers. Your bottom line.

That’s the power of world-class torsion testing—in action.

Ready to Upgrade? Choose Certified Cable Torsion Testing Machine Manufacturers and Exporters

Tired of taking chances with cable reliability? You don’t have to be. Today’s leading cable torsion testing machine manufacturers deliver robust performance, data integrity, and lasting peace of mind. Why risk it with outdated equipment, poorly calibrated systems, or no after-sales support?

Discover the difference with a certified cable torsion testing machine company—where every part, every protocol, every test is tailored for your success. Exporters with experience in global logistics, standards, and compliance make your purchasing journey smooth and effortless.

Ready for a solution that’s built for now—and the future? Contact our team today for a quote, a free technical consultation, or a live demonstration. Elevate your cable quality, boost your global reputation, and put peace of mind back in your production line. Don’t just test—trust.

Contact us today. Choose [Your Company Name]—where innovation, reliability, and customer focus meet. Your cables deserve nothing less than the best.

FAQs About Cable Torsion Testing Machines

Q1: What is a cable torsion testing machine and why is it essential?

A cable torsion testing machine simulates twisting forces on cables to evaluate durability. It’s vital for detecting defects that lead to costly failures in real-world use.

Q2: How do top cable torsion testing machine manufacturers assure quality?

Leading manufacturers use certified materials, precision engineering, and rigorous QA checks. Many are ISO 9001 certified and offer full technical documentation.

Q3: Can a cable torsion testing machine exporter handle international shipments and compliance?

Yes, reputable exporters provide all documents, certifications (CE, UL), and offer logistics support to ensure smooth customs clearance worldwide.

Q4: What product specs should I look for when buying a cable torsion testing machine?

Focus on torque range, sample length, speed control, cycle programmability, data output, and available safety features. Compare specs based on your exact cable diameters and testing standards.

Q5: Is it possible to get a customized cable torsion testing machine?

Absolutely. Many manufacturers offer custom jaw sizes, cycle programming, climate chambers, and integrated data systems to suit your unique industry needs.

Q6: How often should a cable torsion testing machine be calibrated?

Annual calibration is recommended, but high-use labs may need more frequent checks. Reliable companies offer maintenance contracts and on-site calibration.

Q7: What kind of support do cable torsion testing machine companies provide after purchase?

Top companies offer installation, training, technical support, software updates, and fast parts replacement. Full support is key to long-term reliability and investment value.

(cable torsion testing machine)

FAQS on cable torsion testing machine

Q: What is a cable torsion testing machine?

A: A cable torsion testing machine is a device used to measure the twisting strength and flexibility of cables. It helps ensure cable durability and performance under torsional stress. This is crucial for quality assurance in cable manufacturing.Q: How to choose a reliable cable torsion testing machine company?

A: Look for companies with strong industry experience and positive client feedback. A reputable company provides after-sales support and complies with international testing standards. Comparing product features and certifications is also important.Q: What services do cable torsion testing machine manufacturers offer?

A: Manufacturers typically offer machine customization, installation, and training services. They also provide maintenance and technical support for their equipment. Some manufacturers can tailor machines for specific industry needs.Q: How do cable torsion testing machine exporters ensure product quality?

A: Reputable exporters conduct strict quality control checks and provide international certifications for their machines. They also offer detailed documentation and pre-shipment inspections. Reliable exporters communicate clearly regarding shipping and compliance requirements.Q: Why is it important to test cables with a torsion testing machine?

A: Torsion testing identifies defects and ensures cables can withstand repeated twisting in their intended applications. This helps prevent future failures and enhances product reliability. Regular testing is essential for meeting industry safety standards.-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy