Evaluation of Customized Electrode Resistivity Testing Methods for Enhanced Material Performance Analysis

Custom Electrode Resistivity Tests A Comprehensive Overview

Electrical resistivity testing is a widely used method in various fields, including geophysics, civil engineering, and environmental science. One area that has gained increasing attention is the development and utilization of custom electrode designs to enhance the accuracy and effectiveness of resistivity measurements. This article explores the significance of custom electrode resistivity tests, their applications, and the advantages they offer.

Understanding Resistivity Testing

Resistivity tests measure the resistance of soil or rock to the flow of electric current. By applying a known voltage and measuring the resulting current, the resistivity of the material can be calculated. This method provides valuable information about subsurface conditions, such as water content, porosity, and contamination levels. Traditional electrodes often lead to limited accuracy due to their fixed design and standard materials that may not suit every specific testing environment.

The Need for Custom Electrodes

The advent of custom electrodes has transformed the landscape of resistivity testing. Standard electrode configurations can sometimes fail to account for unique geological conditions or project-specific requirements. Custom electrodes are designed to meet particular operational needs, ensuring that they are optimized for the specific conditions under which they are used.

For instance, in highly resistive environments, traditional electrodes may not penetrate adequately, leading to inaccurate readings. Custom-built electrodes can address such issues by enhancing the contact area with the material or using specialized materials that improve conductivity. The flexibility in design allows for tailored solutions that can adapt to varying moisture levels, soil types, and site characteristics.

Applications of Custom Electrode Resistivity Tests

Custom electrode resistivity testing finds its applications in several fields

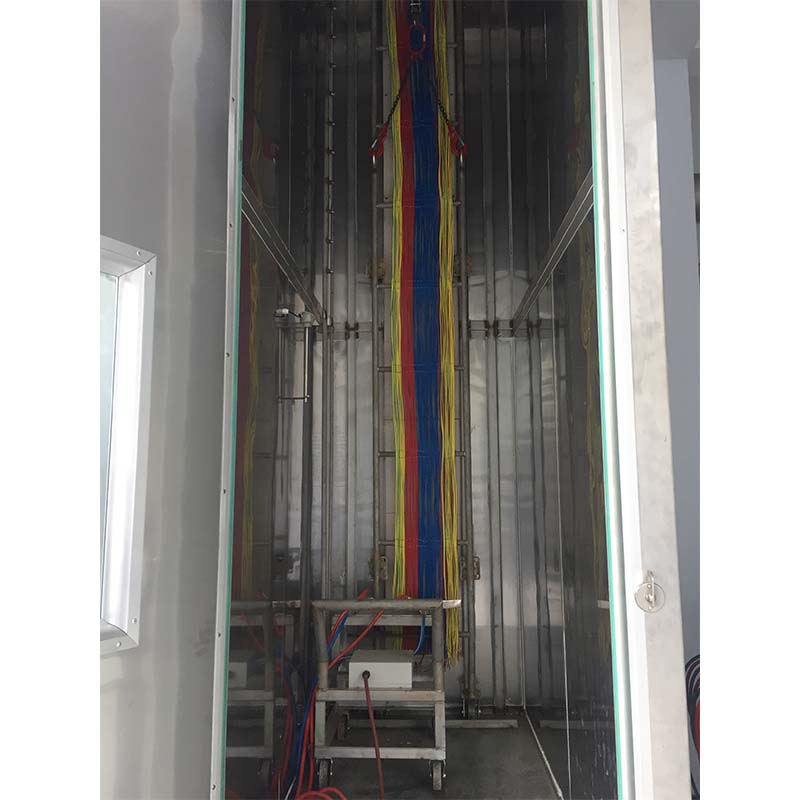

custom electrode resistivity tests

1. Geotechnical Investigations Engineers use resistivity tests to assess soil conditions for construction projects. Custom electrodes can help delineate the boundaries of different soil layers, informing decisions on foundation design and stability.

2. Hydrogeology Understanding groundwater movement is critical for water resource management. Custom electrodes can be designed to measure variations in resistivity in different aquifers, helping hydrogeologists locate and assess potential water supply sources.

3. Environmental Studies Contaminated sites require precise assessments to guide remediation efforts. Custom electrodes can identify variations in resistivity that indicate the presence of contaminants, facilitating targeted cleanup strategies.

4. Archaeological Surveys In archaeology, resistivity testing can reveal buried structures without invasive digging. Custom electrodes tailored for specific site conditions can enhance the detection of archaeological features.

Advantages of Custom Electrode Designs

The advantages of using custom electrodes in resistivity tests include

- Enhanced Accuracy Custom designs optimize contact with the material, minimizing errors that arise from poor electrode performance. - Adaptability They can be tailored for different environments, ensuring that the testing is more effective regardless of soil conditions. - Cost-Effectiveness By improving the quality of data collected, custom electrodes can reduce the need for extensive follow-up investigations, ultimately saving time and resources. - Innovation Custom designs can incorporate the latest materials and technologies, leading to improved performance over traditional electrodes.

Conclusion

Custom electrode resistivity tests represent a significant advancement in the field of electrical resistivity measurement. By tailoring electrodes to meet specific needs, researchers and engineers can achieve more accurate and reliable results in their investigations. This capability not only improves our understanding of subsurface conditions but also enhances decision-making processes in project planning and environmental assessments. As technology continues to evolve, the role of custom electrodes in resistivity testing will likely expand, opening new avenues for exploration and innovation.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy