Factory Testing for Hot Set Cables and Thermal Performance Evaluation Solutions

Cable Hot Set Testing Factory Ensuring Reliability through Rigorous Standards

In today’s fast-paced world, the reliability of electrical cables is paramount. A cable hot set testing factory plays a crucial role in this process, focusing on the testing and validation of cables to ensure they meet stringent industry standards and safety regulations. This facility is dedicated to the evaluation of cables under extreme conditions, which simulates real-world scenarios they may encounter in various applications, such as automotive, aerospace, and energy sectors.

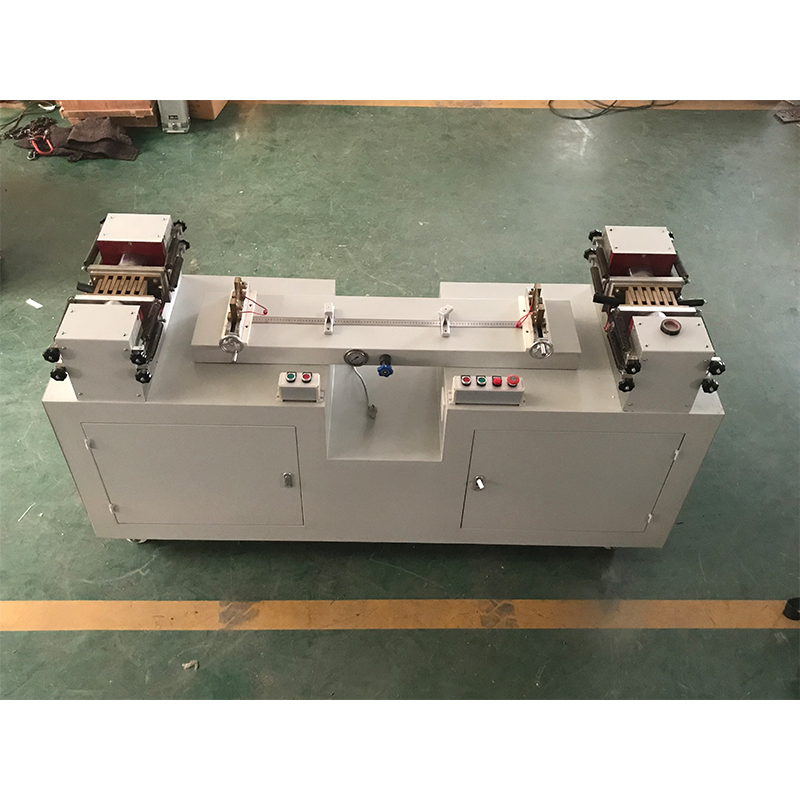

The hot set testing process involves subjecting cables to elevated temperatures while they are under mechanical stress. This tests the material's resilience and its ability to maintain structural integrity and electrical conductivity. The factory is equipped with specialized machinery that can replicate the conditions cables would face in high-heat environments. By heating cables to specific temperatures while applying tension, technicians can observe how the materials react, identifying potential weaknesses and failure points.

cable hot set testing factory

At the core of a cable hot set testing factory is a commitment to quality control. The testing not only ensures that the cables can withstand extreme conditions but also verifies compliance with international standards, such as UL, IEC, and ASTM. These certifications are critical for manufacturers who want to ensure their products are safe and effective in the field. If a cable fails the hot set test, it can lead to potential safety hazards, including electrical fires or equipment failures, making the testing process essential.

Furthermore, the data collected during these tests is invaluable for manufacturers. It helps in refining materials and designs, ultimately leading to the development of safer, more durable products. In an age where electrical components are ubiquitous, having reliable cables is vital for the overall performance of electrical systems.

In summary, a cable hot set testing factory is vital in the electrical manufacturing industry. It serves as a quality assurance hub, ensuring that cables can endure the intense demand placed on them in various applications. By rigorously testing these materials, the factory helps mitigate risks, safeguard equipment, and uphold the reputation of manufacturers. The importance of reliable cables cannot be overstated, and the hot set testing process is a critical step in achieving this goal.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy