Cable Sheath Cutting Machine for Efficient Wire Processing and Manufacturing Solutions

The Evolution and Importance of China’s Cable Sheath Cut Machines

In an era where technology plays a crucial role in manufacturing and production efficiency, machines dedicated to specific tasks are becoming essential. One such innovation is the cable sheath cut machine, particularly in the context of China's rapidly advancing industrial landscape. This machine is designed to facilitate the precise cutting of cable sheaths, a critical step in the cable manufacturing and assembly process.

Understanding Cable Sheath Cutting

Cable sheaths are protective coverings that encase electrical wires, providing insulation and shielding against environmental factors. The manufacturing process of cables involves multiple stages, and cutting the sheath accurately is paramount to ensure the integrity and performance of the final product. A cable sheath cut machine automates this process, offering a level of precision and efficiency that manual cutting methods cannot match.

The Technological Landscape in China

China has become a global leader in manufacturing, and the development of specialized machinery such as cable sheath cut machines exemplifies this trend. These machines integrate advanced technologies, including digital controls, high-speed cutting blades, and automatic feeding mechanisms, allowing manufacturers to optimize their production lines.

With the growing demand for customized cables in various industries such as telecommunications, automotive, and construction, the role of cable sheath cut machines becomes increasingly significant. Manufacturers can leverage the capabilities of these machines to produce cables that meet specific requirements while maintaining high standards of quality.

Benefits of Cable Sheath Cut Machines

1. Precision and Consistency One of the primary advantages of using cable sheath cut machines is the precision they provide. Automated cutting ensures that each sheath is cut to the desired length consistently, reducing waste and increasing the uniformity of the final product.

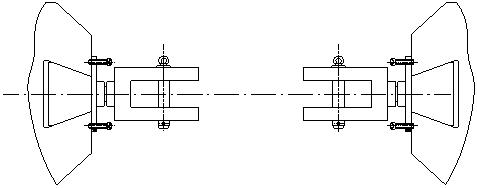

china cable sheath cut machine

2. Increased Efficiency The speed of automated cutting machines significantly exceeds manual methods. This increased efficiency leads to shorter production cycles, allowing manufacturers to meet high demand without compromising on quality.

3. Enhanced Safety Cutting cables manually can pose safety risks to workers. Cable sheath cut machines minimize the need for manual handling of sharp tools, reducing the likelihood of accidents in the workplace.

4. Cost-Effectiveness While the initial investment in automated machinery might be substantial, the long-term savings associated with reduced labor costs, material waste, and improved production speeds make such investments worthwhile.

5. Flexibility and Customization Modern cable sheath cut machines can be programmed to handle various cable sizes and sheath materials, making them versatile tools for manufacturers. This flexibility allows businesses to adapt to changing market demands and produce a wider range of products.

The Road Ahead

As China’s economy continues to grow and evolve, the demand for more sophisticated machinery will increase. Innovations in cable sheath cut machines are likely to focus on integrating smart technology, such as IoT capabilities, to enhance machine performance and facilitate predictive maintenance. This would not only help in optimizing the cutting process but also in preventing downtime, which can be costly for manufacturers.

Moreover, the emphasis on sustainability is expected to shape the future of cable manufacturing processes, including sheath cutting. Equipment manufacturers are likely to explore greener technologies that minimize energy consumption and reduce waste, aligning with global trends towards environmentally responsible production practices.

Conclusion

In conclusion, cable sheath cut machines are a vital component of the manufacturing industry in China, contributing to increased efficiency, safety, and precision in the production of electrical cables. As technology continues to advance, these machines will undoubtedly evolve, enabling manufacturers to adapt to the changing landscape of global industry. The commitment to innovation and quality will ensure that China remains at the forefront of the manufacturing sector, leading the way in the adoption of advanced machinery like cable sheath cut machines to meet the demands of an ever-evolving market.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy