студ . 26, 2025 02:32

Back to list

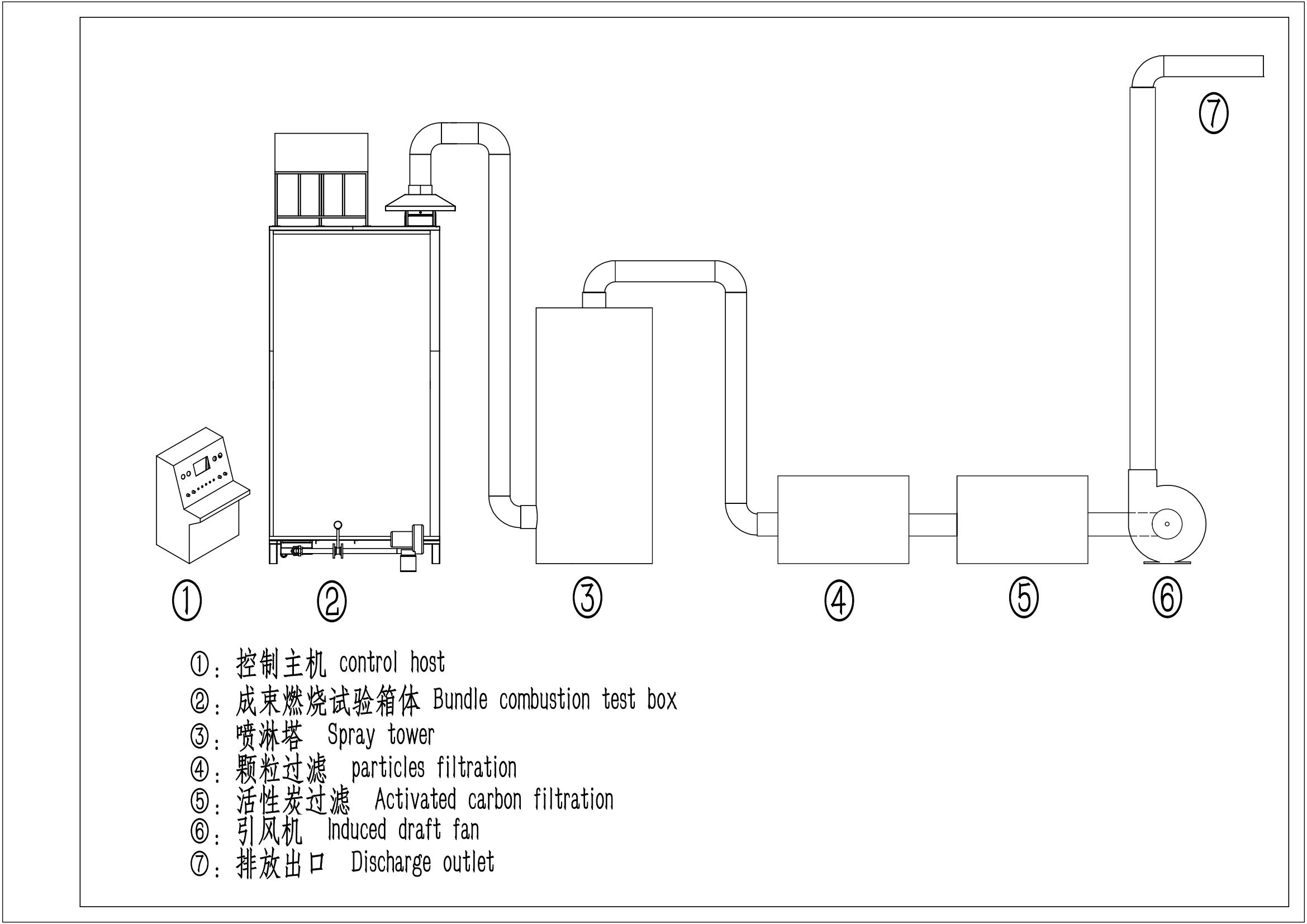

FY-NHZ Cable Fire Resistance Characteristics Test Equipment(Mass Flow Controller)

In the world of cable manufacturing, ensuring the safety and reliability of products is paramount. The custom cable vertical burning test machine plays a crucial role in assessing these attributes. Designed to evaluate flammability and fire resistance, this sophisticated equipment ensures that cables meet stringent industry standards.

Trustworthiness is inherently linked to transparency in the testing process. Manufacturers who use the custom cable vertical burning test machine not only provide detailed reports of their testing procedures but also openly share the modifications and enhancements made to improve cable safety. This transparency builds trust with clients, who can count on the reliability and safety of the products they invest in. In practice, incorporating these machines into your cable testing facility involves a significant investment in both time and resources. Training qualified personnel and maintaining the machine for accuracy are essential components of successful implementation. Companies must also remain abreast of the latest developments in safety standards, constantly updating their testing protocols accordingly. The fundamental benefit of using a custom cable vertical burning test machine is its ability to provide conclusive, repeatable results that support product development and quality assurance processes. As technologies advance and new materials emerge in the cable manufacturing sector, having reliable testing equipment ensures that products remain compliant with ever-evolving fire safety standards. Finally, investing in a custom cable vertical burning test machine is not merely about compliance but also about innovation. It offers manufacturers the opportunity to push the boundaries of what is possible with cable design, creating products that not only meet safety standards but exceed them. This shift towards proactive safety innovation is the hallmark of leading-edge companies dedicated to advancing the role of cables in modern infrastructure and technology solutions.

Trustworthiness is inherently linked to transparency in the testing process. Manufacturers who use the custom cable vertical burning test machine not only provide detailed reports of their testing procedures but also openly share the modifications and enhancements made to improve cable safety. This transparency builds trust with clients, who can count on the reliability and safety of the products they invest in. In practice, incorporating these machines into your cable testing facility involves a significant investment in both time and resources. Training qualified personnel and maintaining the machine for accuracy are essential components of successful implementation. Companies must also remain abreast of the latest developments in safety standards, constantly updating their testing protocols accordingly. The fundamental benefit of using a custom cable vertical burning test machine is its ability to provide conclusive, repeatable results that support product development and quality assurance processes. As technologies advance and new materials emerge in the cable manufacturing sector, having reliable testing equipment ensures that products remain compliant with ever-evolving fire safety standards. Finally, investing in a custom cable vertical burning test machine is not merely about compliance but also about innovation. It offers manufacturers the opportunity to push the boundaries of what is possible with cable design, creating products that not only meet safety standards but exceed them. This shift towards proactive safety innovation is the hallmark of leading-edge companies dedicated to advancing the role of cables in modern infrastructure and technology solutions.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy