Tensile Testing Machine Manufacturer for Accurate Material Strength Evaluation and Quality Assurance

The Importance of Tensile Testing Machines in Material Science

Tensile testing is a critical procedure in material science and engineering, used to determine the mechanical properties of materials such as metals, plastics, and composites. At the heart of this process lies the tensile testing machine, a sophisticated device engineered to measure how a material deforms and ultimately breaks under tension. Understanding the role and operations of a tensile testing machine, particularly in a factory setting, sheds light on its significance in ensuring product quality and safety across various industries.

Understanding Tensile Testing Machines

A tensile testing machine operates by applying tension to a specimen, which is typically in the form of a standardized sample. The machine stretches the material until it reaches its yield point—the stage at which it begins to deform permanently—before eventually breaking. Through this process, vital data is collected, including yield strength, ultimate tensile strength, elongation, and reduction of area. These parameters inform engineers and materials scientists about the material's behavior under stress, helping them to predict how it will perform in real-world applications.

The Working Mechanism

The machine consists of several key components, including a loading frame, a crosshead, load cells, and a data acquisition system. The loading frame provides the necessary strength to withstand high forces, while the crosshead moves to apply tension. Load cells measure the force applied to the specimen, and the data acquisition system records the force and displacement data in real-time. This setup allows for accurate determination of various mechanical properties, making tensile testing machines essential tools in research and development laboratories as well as production environments.

Applications in Industry

Tensile testing machines are utilized in a wide range of industries, including aerospace, automotive, construction, and manufacturing, among others. In the aerospace industry, for example, materials must meet stringent criteria to be deemed safe for flight. Tensile testing helps ensure that materials can withstand the extreme forces encountered during operation. Similarly, in the automotive sector, tensile strength is crucial for ensuring that components can endure high stress while maintaining structural integrity, thereby enhancing vehicle safety.

tensile testing machine factory

In manufacturing, tensile testing machines aid in quality control. By routinely testing raw materials and finished products, manufacturers can detect defects early and make necessary adjustments to their processes. This not only reduces waste but also enhances product reliability, an essential factor in maintaining customer trust.

Innovations in Tensile Testing

As technology advances, so do tensile testing machines. Modern machines are now equipped with digital interfaces, advanced software for data analysis, and even automated systems for specimen handling. These innovations have improved testing accuracy and efficiency, allowing for faster turnaround times in both laboratories and production lines. Moreover, the integration of Artificial Intelligence (AI) in data analysis helps in predicting material behavior based on historical data, further enhancing the decision-making process.

Choosing the Right Manufacturer

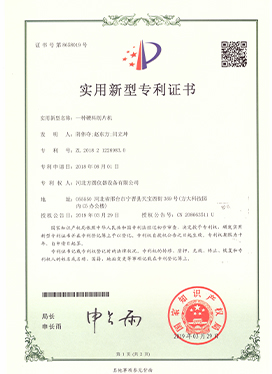

When it comes to tensile testing machines, selecting the right manufacturer can greatly influence the quality and reliability of the testing process. A reputable factory should follow international standards and offer machines that are customizable to meet specific testing requirements. Additionally, the manufacturer should provide comprehensive support, including installation, maintenance, and training, ensuring that clients can maximize the potential of their equipment.

Conclusion

In conclusion, tensile testing machines are indispensable tools in the realm of material science. Their ability to provide in-depth insights into a material's mechanical properties ensures that industries can produce safe and reliable products. As technology continues to evolve, the role of these machines will only become more crucial, driving innovations and quality assurance in various sectors. Investing in high-quality tensile testing equipment from reputable manufacturers is essential for any business aiming to maintain competitive advantage and uphold safety standards in today's dynamic market.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy