Exporters of Cable Hot Set Testing Equipment and Solutions

The Importance of Cable Hot Set Testing for Exporters

In the world of manufacturing and exporting electrical cables, quality assurance is paramount. One of the most critical tests that cable manufacturers employ is hot set testing. This test not only determines the durability and effectiveness of cables but also significantly influences the reputation and reliability of exporters.

What is Cable Hot Set Testing?

Cable hot set testing involves subjecting cables to elevated temperatures for a specified duration to evaluate their thermal performance and structural integrity under stress. The process helps in identifying the cable’s ability to maintain its shape and function when exposed to high temperatures which is particularly relevant for applications in harsh environments.

The testing process usually involves heating a sample of cable at a certain temperature (often around 200 degrees Celsius) for a specific period. After this period, the cable is assessed for any deformation or loss of mechanical properties. This is essential for cables that will be used in high-stress scenarios such as industrial machinery, automotive applications, and outdoor installations.

Why is Hot Set Testing Crucial for Exporters?

1. Compliance with Standards Many international markets have strict regulations regarding electrical components. Conducting hot set tests ensures that cables meet the required safety and performance standards. Compliance not only helps in avoiding legal issues but also enhances the credibility of exporters in global markets.

2. Quality Assurance The competitive nature of the cable market necessitates that exporters provide high-quality products. By incorporating hot set testing into their quality assurance processes, exporters can reduce the risk of failure once cables are in use. This is particularly important for cables meant for critical infrastructure, where any failure could lead to catastrophic results.

3. Customer Trust Reliability is a key factor for customers when selecting a cable supplier. Exporters that can demonstrate thorough testing, including hot set tests, are more likely to earn the trust of their clients. A transparent testing process allows exporters to build a solid relationship with customers who are focused on the long-term performance of their products.

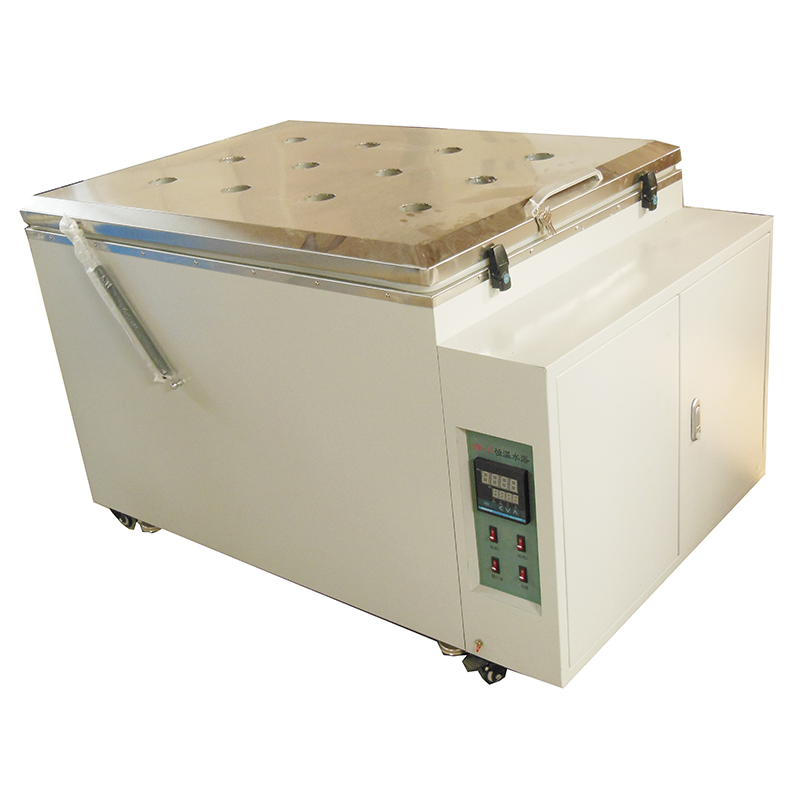

cable hot set testing exporters

4. Reduced Returns and Complaints By ensuring that cables are subjected to rigorous testing, exporters can significantly decrease the likelihood of returns and complaints. Hot set testing helps to identify potential weaknesses before products leave the factory, which can save exporters from the financial and reputational costs associated with product failure in the field.

5. Enhanced Product Development Regular hot set testing can provide valuable data that informs product design and development. This allows exporters to innovate and improve their offerings continually, ensuring they remain competitive in an ever-evolving market.

The Role of Technology

Adopting advanced technology in the hot set testing process can further enhance accuracy and efficiency. Automated testing equipment can provide more reliable results and reduce the chances of human error. Utilizing software to analyze test data can help manufacturers make quicker decisions regarding product adjustments and improvements.

Additionally, advancements in sensor technology and data analytics allow for real-time monitoring of cable performance under stress. Such innovations will enable exporters to optimize products before they reach the market, ensuring they meet the highest standards of quality.

Conclusion

For exporters in the cable industry, conducting thorough hot set testing is not just a regulatory requirement; it is a strategic move that underscores their commitment to quality, reliability, and safety. As global markets become more competitive, investing in rigorous testing processes can yield significant benefits—enhancing customer trust, driving innovation, and ultimately leading to a stronger market presence.

Exporters that embrace hot set testing as part of their quality assurance strategies will position themselves for long-term success, paving the way for increased sales and improved customer satisfaction in the demanding field of electrical cables.

-

reliable-performance-testing-with-advanced-aging-chamber-solutions

NewsAug.23,2025

-

advancing-precision-with-profile-projector-technology

NewsAug.23,2025

-

uv-led-ultraviolet-crosslinking-technology-innovation-and-prospects

NewsAug.23,2025

-

ensuring-safety-and-compliance

NewsAug.23,2025

-

electrical-properties-testing-in-modern-applications

NewsAug.23,2025

-

universal-tensile-testing-machine-applications-in-modern-electrical-and-material-testing

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy