ян. . 17, 2025 02:32

Back to list

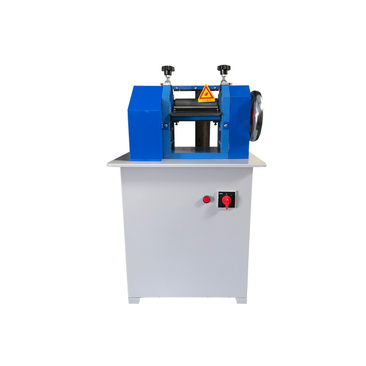

conductor resistance constant temperature tester

In the realm of electrical measurements, the conductor resistance constant temperature tester emerges as a pivotal instrument in ensuring optimal performance and safety. This device measures the resistance of conductors while maintaining a constant temperature, a critical factor as temperature shifts can significantly impact resistance readings. When selecting the right tester, it is crucial to consider several aspects to ensure precision and reliability.

Trustworthiness is paramount in this field, as the implications of inaccurate testing can be severe. Trusted manufacturers provide detailed certifications and documentation proving their equipment meets international standards such as ISO, IEC, or ASTM. This transparency builds confidence, ensuring that the equipment has undergone exhaustive testing for accuracy, safety, and durability. Additionally, positive testimonials from industry leaders and consistent customer support further enhance trust, providing users with assurance and peace of mind. To maximize these benefits, those in pursuit of a suitable conductor resistance constant temperature tester should consider devices with robust features tailored to their specific needs. For instance, a tester's ability to handle a wide range of resistance measurements or its compatibility with various conductor materials can be decisive factors. Tailoring the selection to the operational environment and application helps ensure optimal performance. Involving comprehensive training and user-friendly interfaces, advanced testers foster user competence and confidence. Manufacturers often offer extensive training programs and resources, equipping users with the knowledge to fully harness the device's capabilities. This empowerment translates to more accurate testing and better diagnostic outcomes. In summary, the conductor resistance constant temperature tester is an indispensable tool for professionals in the electrical industry. By focusing on experience, expertise, authoritativeness, and trustworthiness, users can ensure they select devices that meet their precise needs and enhance their operational success. Investing in a quality tester not only streamlines the measurement process but also significantly contributes to the safety and efficiency of electrical systems, underscoring its critical role in modern electrical engineering.

Trustworthiness is paramount in this field, as the implications of inaccurate testing can be severe. Trusted manufacturers provide detailed certifications and documentation proving their equipment meets international standards such as ISO, IEC, or ASTM. This transparency builds confidence, ensuring that the equipment has undergone exhaustive testing for accuracy, safety, and durability. Additionally, positive testimonials from industry leaders and consistent customer support further enhance trust, providing users with assurance and peace of mind. To maximize these benefits, those in pursuit of a suitable conductor resistance constant temperature tester should consider devices with robust features tailored to their specific needs. For instance, a tester's ability to handle a wide range of resistance measurements or its compatibility with various conductor materials can be decisive factors. Tailoring the selection to the operational environment and application helps ensure optimal performance. Involving comprehensive training and user-friendly interfaces, advanced testers foster user competence and confidence. Manufacturers often offer extensive training programs and resources, equipping users with the knowledge to fully harness the device's capabilities. This empowerment translates to more accurate testing and better diagnostic outcomes. In summary, the conductor resistance constant temperature tester is an indispensable tool for professionals in the electrical industry. By focusing on experience, expertise, authoritativeness, and trustworthiness, users can ensure they select devices that meet their precise needs and enhance their operational success. Investing in a quality tester not only streamlines the measurement process but also significantly contributes to the safety and efficiency of electrical systems, underscoring its critical role in modern electrical engineering.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy