Custom Tensile Testing Machine for Evaluating Shear Strength in Various Materials and Applications

Understanding Custom Tensile Testers and Shear Strength Testing

In the realm of materials science and engineering, one of the primary functions is to establish the mechanical properties of materials. Among these properties, tensile strength and shear strength are critical factors that determine how materials behave under various loading conditions. Custom tensile testers play a significant role in accurately measuring these properties, catering to specific testing needs of different materials.

Tensile testing, also known as tension testing, involves pulling a sample material until it deforms or breaks. The tensile tester applies a controlled force to the specimen and measures the resulting elongation, allowing for the determination of tensile strength, yield strength, ductility, and other relevant properties. However, depending on the application and the material being tested, a standard tensile tester may not suffice. This is where custom tensile testers come into play.

Understanding Custom Tensile Testers and Shear Strength Testing

In addition to tensile strength, shear strength is another critical property that needs to be assessed for many applications, especially where materials are subjected to sliding forces. Shear strength refers to the maximum load a material can withstand before failure in the direction parallel to the applied force. This property is essential for evaluating the integrity of adhesive bonds, welded joints, and mechanical fasteners, among others. Custom tensile testers can also be equipped with specific fixtures and setups to perform shear testing efficiently.

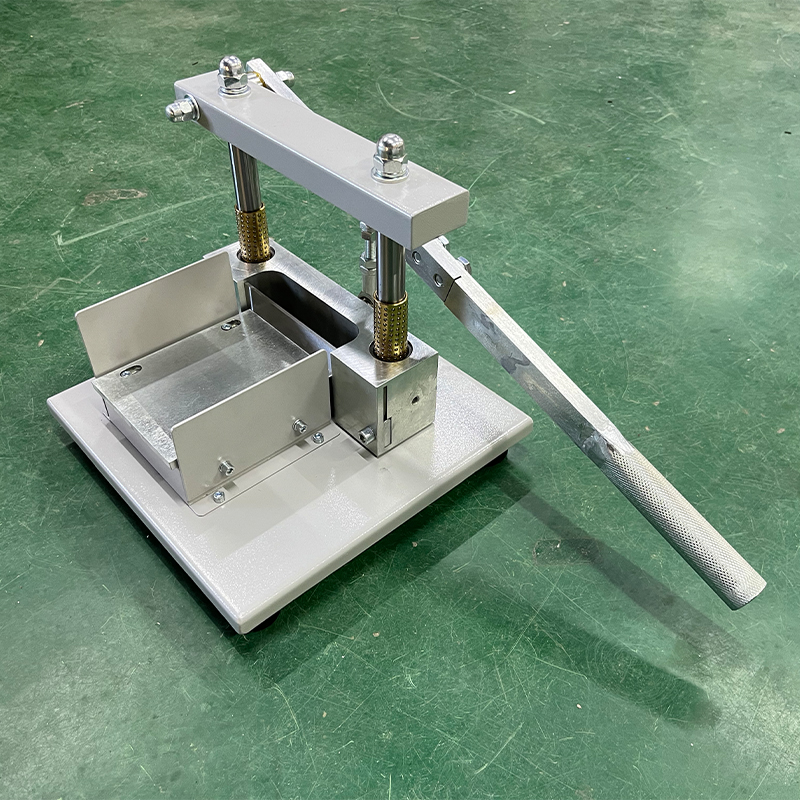

custom tensile tester shear strength

For instance, in industries such as aerospace, automotive, and construction, the materials need to endure high levels of stress without failing. Custom testing solutions enable engineers to simulate real-world conditions and gain valuable insights into material performance. By understanding both tensile and shear strength, engineers can make informed decisions about material selection, design parameters, and safety margins.

Moreover, the results from tensile and shear strength tests directly influence the product development cycle. Materials that pass these tests can undergo be further experimentation to refine their properties, such as improving ductility through alloying or heat treatment. On the other hand, materials that fail to meet strength criteria can be discarded or modified before they are incorporated into final products, saving time and costs associated with unnecessary production.

Implementing custom tensile testers not only enhances the accuracy of mechanical property measurements but also aligns testing practices with industry standards and regulations. Adhering to standards such as ASTM or ISO for tensile and shear strength testing ensures that engineers can trust the results, which are often critical for certifications and compliance.

In summary, custom tensile testers are indispensable tools in the field of materials testing, particularly when evaluating tensile and shear strength. By offering tailored solutions that align with specific testing needs, these instruments enable engineers and researchers to gain a deeper understanding of material behaviors, optimize designs, and ensure safety and quality in end-use applications. As industries continue to evolve and demand higher performance materials, the role of custom testing equipment will only become more critical in meeting these challenges.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy