фев. . 02, 2025 01:06

Back to list

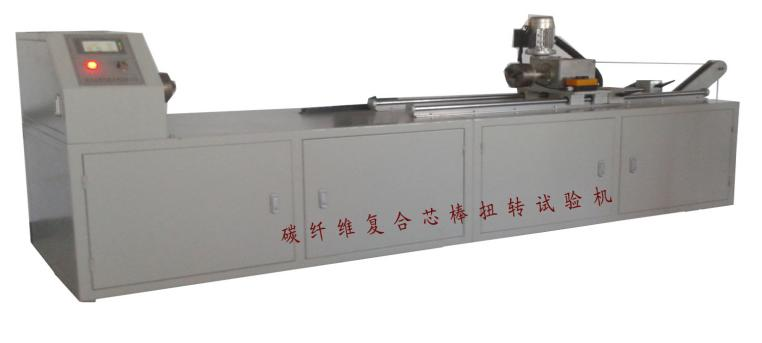

custom tensile testers

In the rapidly evolving landscape of material testing, custom tensile testers have emerged as a revolutionary solution. As industries ranging from aerospace to medical devices constantly innovate, the need for precise and versatile testing machinery only grows. Custom tensile testers, meticulously designed to cater to specific testing requirements, stand out as vital tools that not only provide reliability but also align with highly specialized industry standards.

Trustworthiness in custom tensile testers is crucial, especially given that they're often used in safety-critical environments. Deploying devices that falsely report data or exhibit inconsistencies can have dire consequences, from failed product launches to legal liabilities. Therefore, investing in well-recognized brands known for their commitment to quality and precision drastically reduces these risks. Leading manufacturers invite customer engagement, offering extensive warranties and maintenance programs that solidify buyer confidence. In the competitive market of material testing equipment, custom tensile testers represent a significant investment towards quality assurance and product innovation. They empower companies to push the boundaries of their product capabilities while ensuring quality that stands the test of time. This leads to products that not only meet market needs but also inspire confidence among consumers and stakeholders alike. Another advantage lies in the adaptability of custom tensile testers. As businesses evolve and new materials come into play, these testers can be modified or completely overhauled to keep pace with technological advancements. This aspect protects the client's investment, providing longevity and continuity in their testing capabilities. To conclude, custom tensile testers are more than mere testing apparatuses; they are strategic assets that support a company's pursuit of excellence and innovation. By addressing specific testing needs with precision, they deliver reliable, actionable data that enhances product development cycles and boosts a brand's market reputation. In the grand scheme, having a customized approach to tensile testing facilitates continuous improvement and aligns with the overarching goals of sustainability, efficiency, and consumer satisfaction.

Trustworthiness in custom tensile testers is crucial, especially given that they're often used in safety-critical environments. Deploying devices that falsely report data or exhibit inconsistencies can have dire consequences, from failed product launches to legal liabilities. Therefore, investing in well-recognized brands known for their commitment to quality and precision drastically reduces these risks. Leading manufacturers invite customer engagement, offering extensive warranties and maintenance programs that solidify buyer confidence. In the competitive market of material testing equipment, custom tensile testers represent a significant investment towards quality assurance and product innovation. They empower companies to push the boundaries of their product capabilities while ensuring quality that stands the test of time. This leads to products that not only meet market needs but also inspire confidence among consumers and stakeholders alike. Another advantage lies in the adaptability of custom tensile testers. As businesses evolve and new materials come into play, these testers can be modified or completely overhauled to keep pace with technological advancements. This aspect protects the client's investment, providing longevity and continuity in their testing capabilities. To conclude, custom tensile testers are more than mere testing apparatuses; they are strategic assets that support a company's pursuit of excellence and innovation. By addressing specific testing needs with precision, they deliver reliable, actionable data that enhances product development cycles and boosts a brand's market reputation. In the grand scheme, having a customized approach to tensile testing facilitates continuous improvement and aligns with the overarching goals of sustainability, efficiency, and consumer satisfaction.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy