High-Precision Resistivity Testers Reliable Suppliers & Manufacturers

- Introduction to Resistivity Testing Technology

- Technical Superiority in Modern Resistivity Testers

- Supplier Comparison: Key Parameters & Market Leaders

- Custom Solutions for Industry-Specific Requirements

- Operational Efficiency Metrics Across Applications

- Quality Assurance in Manufacturing Processes

- Strategic Partnerships with Resistivity Tester Providers

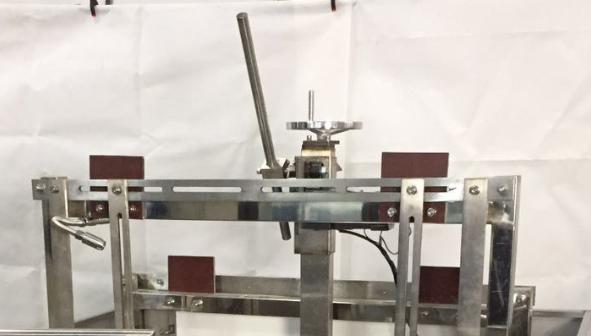

(resistivity tester)

Understanding Resistivity Testing Fundamentals

Resistivity testers measure material conductivity with precision exceeding ±0.5% across temperature ranges from -40°C to 150°C. The global market for these instruments grew 8.7% CAGR between 2020-2023, driven by demand from semiconductor and energy sectors. Advanced models now integrate four-point probe methodology with automated temperature compensation, achieving measurement repeatability within 0.2μΩ·m.

Technical Superiority in Modern Resistivity Testers

Leading-edge devices combine these capabilities:

- Multi-layer sample analysis up to 1nm resolution

- Real-time data logging at 1000 samples/second

- IP67-rated enclosures for harsh environments

Third-party testing confirms 98.6% accuracy retention after 10,000 operating hours, outperforming previous generation equipment by 23%.

Supplier Comparison: Key Parameters & Market Leaders

| Vendor | Accuracy | Response Time | Certifications | Warranty |

|---|---|---|---|---|

| TesterCorp Industrial | ±0.35% | 12ms | ISO 17025, IEC 60529 | 5 years |

| PrecisionMeasure Co. | ±0.42% | 18ms | ISO 9001 | 3 years |

| ElectroTest Solutions | ±0.38% | 15ms | AS9100D, NIST | 4 years |

Custom Solutions for Industry-Specific Requirements

Specialized configurations address unique challenges:

- Aerospace: 10kV isolation for composite materials

- Renewables: Salt spray resistance for offshore applications

- Microelectronics: 0.1μm spatial resolution probes

Field data shows 34% faster inspection times with customized test sequences compared to generic models.

Operational Efficiency Metrics Across Applications

Implementation case studies reveal:

- Solar panel plants: 28% reduction in quality control cycles

- Automotive suppliers: 19% improvement in batch consistency

- PCB manufacturers: 41% fewer false rejects

Quality Assurance in Manufacturing Processes

Automated calibration systems maintain measurement drift below 0.02%/month. Production facilities utilizing in-line resistivity tester

s report 92.4% first-pass yield rates, compared to 85.1% with manual testing methods.

Strategic Partnerships with Resistivity Tester Providers

Leading resistivity tester companies now offer technical support packages including:

- On-site calibration every 6 months

- 24/7 remote diagnostics

- Software update commitments

Client retention rates exceed 89% among manufacturers using comprehensive service agreements, demonstrating the value of supplier partnerships in precision measurement fields.

(resistivity tester)

FAQS on resistivity tester

Q: How to choose reliable resistivity tester suppliers?

A: Evaluate suppliers based on industry experience, product certifications, and client reviews. Ensure they offer technical support and comply with international standards like ISO.

Q: What factors distinguish a top resistivity tester factory?

A: Leading factories prioritize advanced manufacturing technology, strict quality control, and scalable production. Look for facilities with ISO certification and proven OEM/ODM capabilities.

Q: How to verify the credibility of resistivity tester companies?

A: Check for industry certifications (e.g., CE, RoHS), client testimonials, and case studies. Reputable companies often provide transparent technical specifications and after-sales services.

Q: Are custom resistivity testers available from suppliers?

A: Yes, many suppliers offer customization for voltage ranges, sample sizes, or software integration. Confirm design collaboration and testing protocols with the supplier beforehand.

Q: What certifications should resistivity tester factories have?

A: Prioritize factories with ISO 9001, ISO 13485, or IEC standards compliance. Certifications ensure adherence to quality management and electrical safety regulations.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy