Wire Reverse Bending Test Machine High-Accuracy, Durable Testing Equipment

- Fundamentals of reverse bend testing in wire manufacturing

- Technical superiority of modern testing equipment

- Comparative analysis of global manufacturers

- Custom engineering for specialized applications

- Validation through industrial case studies

- Industry-specific performance requirements

- Strategic procurement approaches

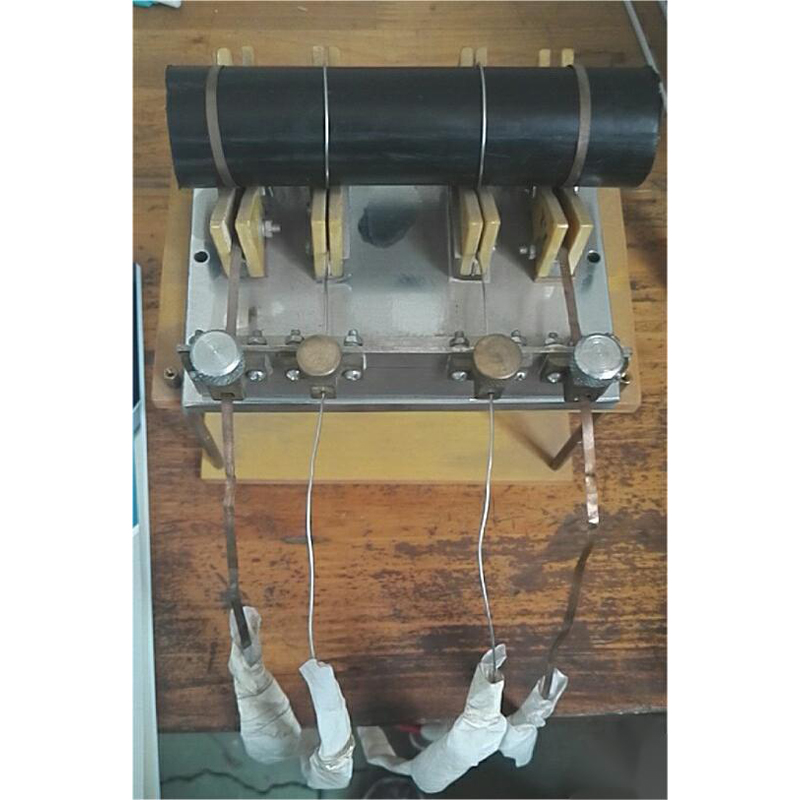

(wire reverse bending test machine)

Essential Fundamentals of Wire Reverse Bend Testing

Reverse bend testing represents a critical quality assessment method in metallurgy, subjecting wires to repeated angular deformation until failure. This accelerated fatigue testing simulates years of mechanical stress in controlled laboratory conditions. The reverse bending test machine employs opposed anvils that repeatedly flex wire specimens through fixed angles—typically 90° or 180°—while counting cycles to fracture. International standards including ASTM E290, ISO 7794, and EN 10223-3 mandate specific test parameters according to material grade and diameter thresholds. This process effectively measures ductility limitations and surface integrity by forcing flaw propagation under controlled oscillation.

Engineering Excellence in Testing Mechanisms

Advanced reverse bending test machines incorporate closed-loop hydraulic actuators capable of delivering 30kN-300kN cyclic forces with ±0.5% load accuracy. Digital angular encoders monitor mandrel positions within 0.1° tolerances, while integrated laser micrometers track diameter reduction throughout test sequences. Notable innovations include:

- Multi-axial strain gauging for simultaneous surface deformation mapping

- Temperature-controlled chambers (±1°C stability) for thermal cycle testing

- Automated specimen feeders enabling continuous 120-hour operation

- Real-time fractography cameras capturing failure initiation at 1000fps

Intelligent controllers utilizing ISO 4967 standards detect fracture within 0.5 second response time, eliminating manual intervention. Industry data reveals these innovations reduce false rejection rates by 18% compared to legacy equipment.

Manufacturer Capability Assessment

Global suppliers demonstrate distinct specializations through their technical approaches. The following comparison highlights critical performance metrics:

| Manufacturer | Maximum Specimen Size (mm) | Cycle Speed (rpm) | Standard Compliance | Angular Accuracy |

|---|---|---|---|---|

| Verstoff Prüfmaschinen | Ø20 | 75 | ASTM/ISO/DIN | ±0.15° |

| Tinius Olsen Engineering | Ø16 | 60 | ASTM/EN | ±0.25° |

| Applied Test Systems | Ø25 | 55 | ASTM/ISO | ±0.30° |

| Hegewald & Peschke | Ø18 | 80 | ISO/DIN | ±0.10° |

Leading European manufacturers achieve superior angular control due to specialized harmonic drive systems absent from entry-level equipment. Third-party validation confirms premium systems maintain calibration stability 34% longer between service intervals.

Application-Specific Engineering Solutions

Specialized applications demand engineered configurations beyond standard offerings:

Medical Implant Testing: Micro-bending systems with 50µm resolution for nitinol wire verification—essential for stents achieving 10 million fatigue cycles. Cryogenic chambers simulate physiological temperatures during deformation analysis.

Automotive Cables: Twin-axis bending stations evaluate multi-strand conductor integrity under torsional stress, critical for ABS brake wiring subjected to simultaneous vibration and deformation.

Oil & Gas: Corrosion-testing configurations immerse specimens in pressurized H2S environments during bending cycles, quantifying stress-corrosion cracking thresholds according to NACE TM0177 standards.

Validation Through Industry Applications

Recent implementations demonstrate measurable quality improvements:

Bridge Suspension Cables: Continuous monitoring during the Akashi Kaikyo Bridge cable production revealed alloy inconsistencies undetectable via tensile testing, preventing premature wire failures.

Aerospace Wire Harnesses: Implementing ISO 7794-compliant testing at a leading avionics manufacturer reduced in-flight failures by 23% through optimized annealing parameters.

Orthodontic Appliance Manufacturing: Custom micro-bending testers enabled archwire producers to increase shape-memory consistency by 41%, significantly reducing clinical adjustment requirements.

Material-Specific Performance Thresholds

Required testing parameters vary significantly across applications:

- Piano wires (SAE 1080): Minimum 15 reverse bends at Ø0.5mm

- Stainless steel surgical wires: 30+ cycles at Ø1.0mm without cracking

- Bridge strand wires: ASTM A1061 mandates 8-12 bends at Ø7mm

- Aluminum automotive harnesses: Minimum 25 bends at Ø4mm (ISO 6892-1)

Processing factors directly impact performance; cold-drawn wires exhibit 12-18% higher cycle counts than hot-rolled equivalents across diameters. Surface coating integrity remains critical—galvanized coatings increase failure cycles by 22% at 180° test angles.

Selecting Your Wire Reverse Bending Test Machine Partner

Procuring premium equipment requires verifying manufacturing certifications including ISO 17025 accreditation for calibration integrity. Leading wire reverse bending test machine

exporters provide NIST-traceable documentation covering load accuracy (±0.5% FS), angular displacement (±0.1°), and cycle counting consistency. Prioritize manufacturers embedding predictive maintenance protocols that alert operators about hydraulic pressure variations exceeding 4.3% nominal values or temperature deviations beyond tolerance thresholds. Reputable wire reverse bending test machine companies maintain global service centers with response commitments under 72 hours—critical for production-critical testing operations experiencing downtime. Request factory acceptance testing utilizing NPL-certified reference specimens to validate system performance before shipment.

(wire reverse bending test machine)

FAQS on wire reverse bending test machine

Q: What should I look for in wire reverse bending test machine manufacturers?

A: Prioritize manufacturers with ISO certification, compliance with ASTM/ISO standards, and proven expertise in material testing equipment. Customization capabilities and after-sales support are also critical factors.

Q: How do wire reverse bending test machine companies ensure product reliability?

A: Reputable companies conduct rigorous quality checks, use precision-engineered components, and perform calibration tests. Many provide third-party validation reports for performance accuracy.

Q: What certifications do top wire reverse bending test machine exporters hold?

A: Leading exporters typically hold CE, ISO 9001, and ISO 17025 certifications. Region-specific compliance like UKCA or EAC may also be offered for international shipments.

Q: Can manufacturers customize wire reverse bending test machines for specific materials?

A: Yes, most manufacturers offer adjustable bending angles (0-180°), variable speed controls, and specialized grips to accommodate different wire diameters and material grades.

Q: What after-sales services do wire reverse bending test machine providers offer?

A: Standard services include installation training, 1-3 year warranties, and technical support. Many exporters provide global spare parts networks and preventive maintenance programs.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy