Equipment for Measuring Conductor Resistance in Manufacturing Facilities

Understanding Conductor Resistance Measurement Equipment A Guide to Factories and Innovations

In the modern electrical landscape, the importance of conductor resistance measurement cannot be overstated. This fundamental parameter ensures the reliability, efficiency, and safety of electrical systems. As a result, the demand for high-quality conductor resistance measurement equipment has surged, prompting a proliferation of factories dedicated to its development and manufacturing.

Conductor resistance measurement equipment is essential for evaluating the resistance of conductors in various electrical applications. This equipment is pivotal in industries such as power generation, telecommunications, railways, and manufacturing. Accurate measurements help in detecting potential issues that could lead to energy losses, overheating, or even catastrophic failures in electrical systems.

The Role of Factories in Equipment Production

The manufacturing process of conductor resistance measurement equipment involves sophisticated technology and stringent quality control measures. Factories specializing in this equipment often employ advanced manufacturing techniques, utilizing precision engineering to ensure the reliability and accuracy of their products.

1. Design and Development Factories begin the process by designing equipment that meets international standards. The design phase incorporates feedback from industry professionals to ensure the instruments are user-friendly and meet specific measurement needs. This includes considerations for portability, data logging capabilities, and interfaces for easy data transfer.

2. Material Selection The quality of materials used in the construction of conductor resistance measurement equipment directly impacts its performance. Factories source high-quality components that can withstand varying environmental conditions. Robust materials ensure longevity and reliability, crucial for equipment utilized in demanding industrial settings.

3. Testing and Calibration Before any equipment leaves the factory floor, it undergoes rigorous testing and calibration processes. This phase is critical; it guarantees that each unit meets the specified accuracy standards. Factories often employ automated testing systems alongside manual checks to ensure the consistency and precision of the measurements.

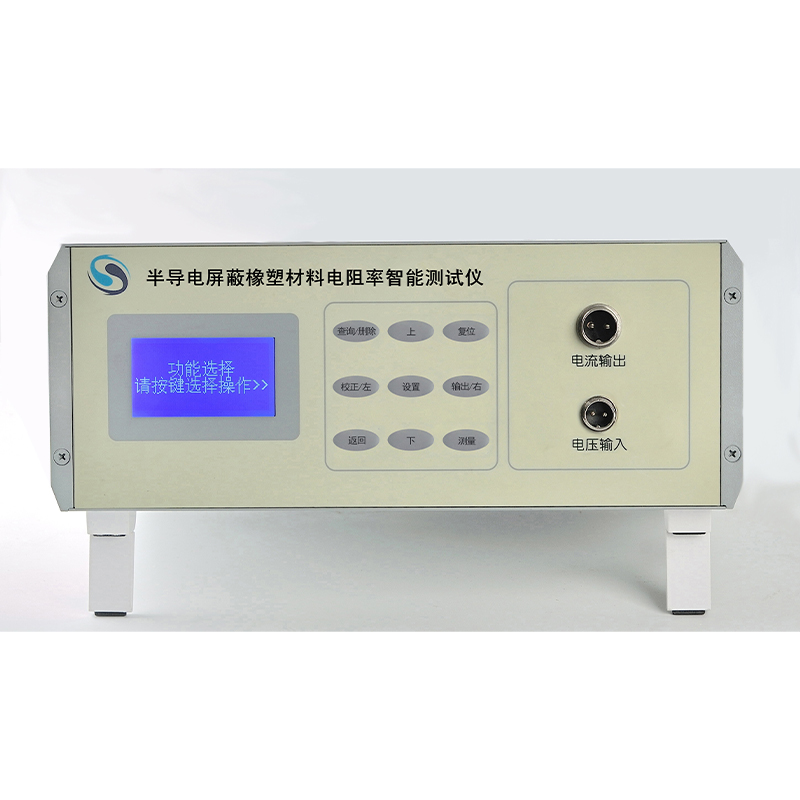

conductor resistance measurement equipment factories

Innovations in Conductor Resistance Measurement Equipment

As advancements in technology continue to reshape various sectors, conductor resistance measurement equipment is no exception. Factories are now integrating cutting-edge technologies, such as IoT (Internet of Things), artificial intelligence (AI), and cloud computing into their products.

1. Smart Measurement Devices Today's equipment often features smart capabilities that allow real-time monitoring and remote diagnostics. This innovation not only enhances measurement accuracy but also enables predictive maintenance, minimizing downtime and maintenance costs.

2. Data Analysis The incorporation of data analytics tools into measurement equipment allows engineers to analyze resistance trends over time. This feature provides invaluable insights that can guide decision-making processes regarding system upgrades or replacements.

3. Sustainability Initiatives Many factories are increasingly focusing on sustainability, adopting eco-friendly manufacturing practices and materials. This shift not only helps reduce the environmental impact of production but also promotes the use of energy-efficient equipment in the field.

Future of Conductor Resistance Measurement Equipment

The future of conductor resistance measurement equipment is promising, driven by ongoing technological advancements and the growing emphasis on energy efficiency and sustainability. As industries evolve and the demand for reliable electrical systems grows, factories will continue to innovate, ensuring that their products remain at the forefront of measurement technology.

In conclusion, conductor resistance measurement equipment plays a critical role in ensuring the reliability and safety of electrical systems across various industries. Factories involved in the production of this equipment are tasked with not only maintaining high standards of quality and innovation but also adapting to the ever-changing technological landscape. As we look ahead, the evolution of this equipment will undoubtedly shape the future of electrical engineering, promoting safer and more efficient electrical systems worldwide.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy