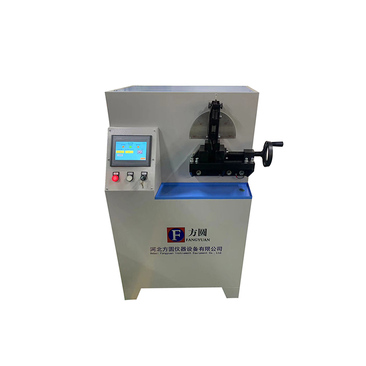

dumbbell die cutter factories

The Evolution and Importance of Dumbbell Die Cutter Factories

In the realm of manufacturing and industrial machinery, the term dumbbell die cutter may not ring familiar to many. However, this particular type of die cutter plays a crucial role in various sectors ranging from packaging to textiles. As a specialized tool designed to create precise cuts in materials, the dumbbell die cutter is favored for its efficiency and versatility. In this article, we will explore the importance of dumbbell die cutter factories, their technological advancements, and their impact on modern manufacturing.

Understanding Dumbbell Die Cutters

Dumbbell die cutters derive their name from the design of the cutting die, which resembles a dumbbell. The die-cutting process involves placing a material—such as paper, rubber, or fabric—between two plates. The die is then pressed into the material, creating a shape or pattern as the material is cut. This method ensures clean edges and minimal waste, making it an effective option for mass production.

The Role of Factories in Production

Dumbbell die cutter factories serve as the backbone for producing these essential tools. These factories employ skilled artisans and engineers who collaborate to design and manufacture precision dies. Quality control is paramount, and factories utilize stringent testing protocols to ensure that every die meets industry standards. The ability to produce high-quality, durable dies allows manufacturers to create consistent products that meet consumer demands.

Technological Advancements

Over the years, dumbbell die cutter factories have embraced technological advancements that enhance production efficiency. Automation has revolutionized the manufacturing process, allowing for faster cutting speeds and reduced labor costs. Modern factories may employ computer numerically controlled (CNC) machines that guarantee precision and replicate intricate designs with remarkable accuracy. Furthermore, software integration allows for rapid prototyping, enabling manufacturers to test new designs before committing to large-scale production.

Another advancement is the use of eco-friendly materials and processes. As sustainability becomes increasingly important in manufacturing, many factories are sourcing biodegradable materials and adopting green practices in their production lines. This approach not only benefits the environment but also appeals to a growing consumer base that prioritizes sustainability.

dumbbell die cutter factories

Economic Impact

Dumbbell die cutter factories are significant contributors to the economy. By producing essential tools for various industries, they facilitate the creation of finished products that consumers rely on daily. From packaging materials to apparel, the influence of die cutters is extensive. Moreover, these factories often create employment opportunities, boosting local economies and providing stable jobs for skilled workers.

Globally, the demand for dumbbell die cutters continues to grow, driven by industries such as automotive, textiles, food packaging, and more. As companies strive for efficiency and cost-effectiveness, the need for quality die-cutting solutions is paramount. Consequently, factories must adapt to market changes and technological advancements to remain competitive.

Challenges and Future Prospects

Despite their significance, dumbbell die cutter factories face challenges. Fluctuating raw material prices, competition from overseas manufacturers, and the need for continuous innovation can strain operations. To counter these challenges, factories are investing in research and development to improve their products and processes. Collaborative partnerships with other manufacturers and educational institutions can also foster innovation and streamline production.

Looking ahead, the future of dumbbell die cutter factories appears promising. With the rise of e-commerce and custom manufacturing, there is a growing need for unique packaging solutions that require precise cuts. As industries evolve and consumer preferences change, the adaptability of these factories will be crucial in meeting the demands of the market.

Conclusion

In conclusion, dumbbell die cutter factories are integral to the manufacturing landscape. Their commitment to producing high-quality cutting tools, embracing technological advancements, and contributing to the economy underscores their importance. As the industry evolves, these factories will continue to play a pivotal role in shaping the future of manufacturing and ensuring the efficient production of goods that consumers depend on. Through innovation and strategic adaptations, dumbbell die cutter factories are poised to thrive in an ever-changing market.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy