জুন . 28, 2024 11:30

Back to list

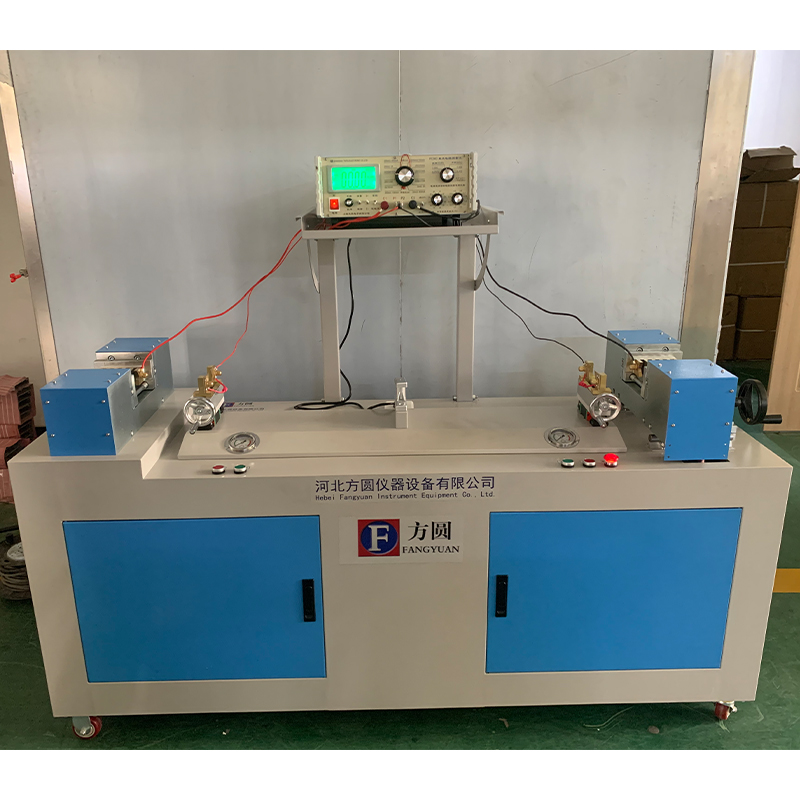

Manufacturers of Clamps for Tensile Testers Quality and Reliability Assurance

Exploring the World of Clamps for Tensile Testers – A Manufacturer’s Perspective

In the realm of materials science and engineering, tensile testing is a cornerstone of quality control and research. This rigorous process evaluates the mechanical properties of materials, including their strength, ductility, and elasticity under tension. At the heart of this testing lies the often-underappreciated component clamps for tensile testers. These devices secure the specimen in place, ensuring accurate measurements that are crucial for analysis. In this article, we delve into the world of clamps designed specifically for tensile testers from a manufacturer's viewpoint.

The manufacturing of clamps for tensile testers is a specialized niche requiring precision and innovation. These clamps must be capable of gripping various material samples firmly while distributing force evenly to prevent premature failure or slippage. Our company, a leading manufacturer in this sector, prides itself on crafting high-performance clamps using advanced materials and cutting-edge technology.

Our product line includes a variety of clamp designs tailored to different applications. For instance, our flat-faced clamps are ideal for standard metal coupons, while our jaw-faced clamps provide a stronger grip suitable for more challenging materials such as plastics or composites. We also offer customizable clamp solutions for unique sample geometries or bespoke testing protocols We also offer customizable clamp solutions for unique sample geometries or bespoke testing protocols We also offer customizable clamp solutions for unique sample geometries or bespoke testing protocols We also offer customizable clamp solutions for unique sample geometries or bespoke testing protocols

We also offer customizable clamp solutions for unique sample geometries or bespoke testing protocols We also offer customizable clamp solutions for unique sample geometries or bespoke testing protocols clamps for tensile testers manufacturers.

Quality assurance is paramount in our production process. Each clamp undergoes rigorous testing to ensure it can withstand the extreme forces encountered during tensile tests without deformation or failure. Our commitment to excellence extends beyond our products; we provide comprehensive customer support and training to guarantee that users get the most accurate results possible from their tensile testers.

Innovation is the driving force behind our continuous improvement. Our R&D team is constantly exploring new materials and design enhancements to stay ahead in performance and reliability. With the advent of smart technologies, we are integrating sensors and data analytics into our clamp systems to offer real-time feedback during tests, further refining the accuracy of the results obtained.

As manufacturers of clamps for tensile testers, we stand at the intersection of engineering, precision, and innovation. Our products enable scientists and engineers worldwide to push the boundaries of material science, ensuring that advancements in technology and infrastructure are built on a foundation of reliable data. The next time you encounter a tensile test report, remember that behind every measurement lies a sophisticated piece of equipment—our clamps—silently contributing to the discovery and development of stronger, more durable materials.

clamps for tensile testers manufacturers.

Quality assurance is paramount in our production process. Each clamp undergoes rigorous testing to ensure it can withstand the extreme forces encountered during tensile tests without deformation or failure. Our commitment to excellence extends beyond our products; we provide comprehensive customer support and training to guarantee that users get the most accurate results possible from their tensile testers.

Innovation is the driving force behind our continuous improvement. Our R&D team is constantly exploring new materials and design enhancements to stay ahead in performance and reliability. With the advent of smart technologies, we are integrating sensors and data analytics into our clamp systems to offer real-time feedback during tests, further refining the accuracy of the results obtained.

As manufacturers of clamps for tensile testers, we stand at the intersection of engineering, precision, and innovation. Our products enable scientists and engineers worldwide to push the boundaries of material science, ensuring that advancements in technology and infrastructure are built on a foundation of reliable data. The next time you encounter a tensile test report, remember that behind every measurement lies a sophisticated piece of equipment—our clamps—silently contributing to the discovery and development of stronger, more durable materials.

We also offer customizable clamp solutions for unique sample geometries or bespoke testing protocols We also offer customizable clamp solutions for unique sample geometries or bespoke testing protocols

We also offer customizable clamp solutions for unique sample geometries or bespoke testing protocols We also offer customizable clamp solutions for unique sample geometries or bespoke testing protocols clamps for tensile testers manufacturers.

Quality assurance is paramount in our production process. Each clamp undergoes rigorous testing to ensure it can withstand the extreme forces encountered during tensile tests without deformation or failure. Our commitment to excellence extends beyond our products; we provide comprehensive customer support and training to guarantee that users get the most accurate results possible from their tensile testers.

Innovation is the driving force behind our continuous improvement. Our R&D team is constantly exploring new materials and design enhancements to stay ahead in performance and reliability. With the advent of smart technologies, we are integrating sensors and data analytics into our clamp systems to offer real-time feedback during tests, further refining the accuracy of the results obtained.

As manufacturers of clamps for tensile testers, we stand at the intersection of engineering, precision, and innovation. Our products enable scientists and engineers worldwide to push the boundaries of material science, ensuring that advancements in technology and infrastructure are built on a foundation of reliable data. The next time you encounter a tensile test report, remember that behind every measurement lies a sophisticated piece of equipment—our clamps—silently contributing to the discovery and development of stronger, more durable materials.

clamps for tensile testers manufacturers.

Quality assurance is paramount in our production process. Each clamp undergoes rigorous testing to ensure it can withstand the extreme forces encountered during tensile tests without deformation or failure. Our commitment to excellence extends beyond our products; we provide comprehensive customer support and training to guarantee that users get the most accurate results possible from their tensile testers.

Innovation is the driving force behind our continuous improvement. Our R&D team is constantly exploring new materials and design enhancements to stay ahead in performance and reliability. With the advent of smart technologies, we are integrating sensors and data analytics into our clamp systems to offer real-time feedback during tests, further refining the accuracy of the results obtained.

As manufacturers of clamps for tensile testers, we stand at the intersection of engineering, precision, and innovation. Our products enable scientists and engineers worldwide to push the boundaries of material science, ensuring that advancements in technology and infrastructure are built on a foundation of reliable data. The next time you encounter a tensile test report, remember that behind every measurement lies a sophisticated piece of equipment—our clamps—silently contributing to the discovery and development of stronger, more durable materials. Latest news

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy