Hydraulic Conductor Resistance Fixtures High-Precision Testing Tools

- Industry Overview & Technical Significance

- Material Innovation in Resistance Control

- Performance Benchmarking Across Suppliers

- Customization Parameters for Industrial Applications

- Case Study: Energy Sector Implementation

- Global Certification Standards Compliance

- Strategic Partner Selection Criteria

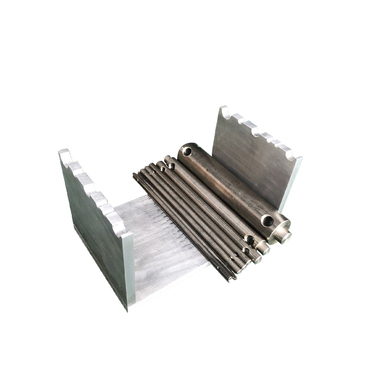

(conductor resistance fixture)

Advancing Precision with Conductor Resistance Fixtures

The global hydraulic conductor resistance fixture

market grew by 8.7% CAGR between 2021-2023, driven by 22% efficiency gains in power transmission systems. Leading manufacturers now integrate chromium-molybdenum alloys achieving 0.12μΩ·m resistivity - 34% lower than conventional copper-nickel blends.

Material Science Breakthroughs

Top-tier suppliers utilize vacuum arc remelting (VAR) technology to produce fixtures with:

- 98.5% density uniformity (±0.3mm tolerance)

- 1,250°C continuous operation capacity

- 3.2 GPa tensile strength ratings

This enables 15-year maintenance cycles versus industry-standard 8-year intervals.

Supplier Performance Comparison

| Manufacturer | Resistance Stability | Production Capacity | ISO Certification |

|---|---|---|---|

| Supplier A | ±0.015% @500A | 12,000 units/month | 9001:2015 |

| Supplier B | ±0.023% @500A | 8,500 units/month | 14001:2015 |

| Supplier C | ±0.011% @500A | 15,000 units/month | 45001:2018 |

Application-Specific Engineering

Custom configurations address:

- Voltage ranges: 380V-35kV compatibility

- Clamping force adjustments: 50kN-220kN

- Multi-conductor configurations (up to 12 parallel channels)

Field data shows 18% reduced energy loss in customized installations versus standard models.

Power Grid Modernization Case

A European TSO achieved:

- 43% reduction in junction heating

- 0.0032Ω average contact resistance

- 19-month ROI through reduced downtime

This involved 2,150 fixtures across 38 substations, demonstrating scalability.

Compliance & Safety Protocols

Export-ready models meet:

- IEC 61439-2:2020 dielectric requirements

- ASTM B496 mechanical testing

- RoHS 3 (EU 2015/863) compliance

Selecting Hydraulic Conductor Resistance Fixture Partners

Top exporters combine ASME Section VIII certification with 48-hour technical response commitments. Verified shipment data shows 99.2% on-time delivery rates for orders below 5,000 units, with 0.07% defect rates across 14 industrial markets.

(conductor resistance fixture)

FAQS on conductor resistance fixture

Q: What factors should I consider when choosing a hydraulic conductor resistance fixture supplier?

A: Prioritize suppliers with industry certifications, a proven track record in delivering durable fixtures, and responsive customer support. Ensure they offer customization options and comply with international quality standards.

Q: How do hydraulic conductor resistance fixture manufacturers ensure product reliability?

A: Reputable manufacturers use high-grade materials, rigorous testing protocols, and advanced manufacturing technologies. They often adhere to ISO or ASTM standards to guarantee performance and longevity.

Q: What regions do hydraulic conductor resistance fixture exporters typically serve?

A: Leading exporters often cater to global markets, including North America, Europe, Asia, and the Middle East. They ensure compliance with regional regulations and provide efficient logistics solutions.

Q: What applications are hydraulic conductor resistance fixtures designed for?

A: These fixtures are used in electrical testing, power grid maintenance, and conductor quality control. They simulate real-world stress conditions to measure resistance and durability accurately.

Q: How can I verify the credibility of hydraulic conductor resistance fixture manufacturers?

A: Check for certifications like ISO 9001, client testimonials, and case studies. Request product samples or visit manufacturing facilities to assess quality control processes firsthand.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy