universal tensile tester

Understanding the Universal Tensile Tester A Key Instrument in Material Testing

The universal tensile tester is an essential device used in material science and engineering to evaluate the mechanical properties of materials. This versatile testing machine enables researchers and engineers to perform tensile tests, compression tests, bending tests, and several other assessments that provide valuable data on the strength, ductility, and overall behavior of materials under various loads. With the ongoing advancement of materials technology, the universal tensile tester has become increasingly important in both industrial applications and academic research.

What is a Universal Tensile Tester?

A universal tensile tester consists of a framework that supports a load cell, grips for holding the sample material, and a control system to monitor and record test parameters. Typically, the machine is equipped with a crosshead that moves vertically, applying a controlled load to the material under test. The main function of the tester is to stretch a sample until it fails, allowing us to measure crucial factors such as yield strength, ultimate tensile strength, elongation, and reduction of area.

Importance in Material Testing

The universal tensile tester plays a fundamental role in ensuring the quality and safety of materials used in various industries, including construction, aerospace, automotive, and manufacturing

. By understanding how materials behave under stress, engineers can make informed choices about which materials to use for specific applications. For example, knowing the tensile strength of steel used in a bridge is critical to ensuring its structural integrity.Moreover, the data obtained from tensile tests helps in quality control processes. Manufacturers can regularly assess the mechanical properties of their materials, ensuring they meet predefined specifications. Any deviations can be addressed promptly, allowing companies to maintain high standards and compliance with safety regulations.

Key Parameters Measured

1. Tensile Strength The maximum amount of tensile stress that a material can withstand before failure. This is a critical measurement for assessing the material's capability to resist breaking under tension.

universal tensile tester

2. Yield Strength The stress at which a material begins to deform plastically. Beyond this point, the material will not return to its original shape, making knowledge of yield strength essential for applications where deformation is unacceptable.

3. Elongation A measure of how much a material stretches before breaking. It is expressed as a percentage of the original length and indicates the ductility of the material. Highly ductile materials exhibit significant elongation before fracture, while brittle materials do not.

4. Reduction of Area This parameter indicates how much the cross-sectional area of the material decreases at the point of fracture. It is another measure of ductility and helps determine how materials will behave under different loading conditions.

Applications Across Industries

The applications of a universal tensile tester extend beyond mere research and development. In the construction industry, for example, it is crucial for testing the strength of concrete and steel. In the automotive sector, manufacturers assess the durability of various components to ensure safety and longevity. The aerospace industry relies on tensile testing to verify that the materials used in aircraft can withstand extreme conditions during flight.

In addition to traditional industries, the rise of advanced materials, including composites and polymers, has expanded the applicability of universal tensile testers. These materials often exhibit unique properties that require specialized testing techniques to fully characterize their behavior under stress.

Conclusion

In summary, the universal tensile tester is a pivotal tool in the field of material testing, providing essential insights into the mechanical properties of various substances. Its ability to measure tensile strength, yield strength, elongation, and reduction of area allows for meticulous evaluation and quality assurance across multiple industries. As material science continues to evolve, the importance of this testing apparatus will only grow, ensuring safety, reliability, and innovation in material use and development. Understanding and utilizing the universal tensile tester is imperative for engineers and researchers committed to advancing material technology and optimizing performance in real-world applications.

-

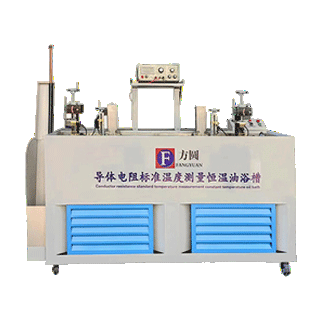

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy