cable winding test machine exporters

The Cable Winding Test Machine Exporters Ensuring Quality and Reliability in Manufacturing

In the ever-evolving world of electronics and electrical engineering, the demand for high-quality cables is paramount. The cable industry plays a crucial role in various sectors, including telecommunications, power distribution, and automotive manufacturing. To ensure that these cables meet the required standards of safety and performance, manufacturers rely heavily on advanced testing equipment. One such vital piece of equipment is the cable winding test machine. This article will explore the importance of cable winding test machines, their functionalities, and the role of exporters in the global market.

The Importance of Cable Winding Test Machines

Cable winding test machines are designed to evaluate the physical and electrical properties of cables. These machines simulate real-world conditions to assess how cables will perform under various stresses. By using these machines, manufacturers can identify potential faults and weaknesses in their products before they reach the market. This pre-emptive testing can save companies significant costs associated with recalls, warranty claims, and damaged reputations.

One of the critical aspects of these machines is their ability to perform a series of tests, including tensile strength, elongation, and insulation resistance. These tests are vital in determining not only the durability of the cables but also their safety. For instance, cables that are used in high voltage settings must withstand significant stress, and failure to do so could result in catastrophic incidents.

The Functions of Cable Winding Test Machines

Cable winding test machines come equipped with various features designed to enhance their testing capabilities. Modern machines often include automated systems for precision testing, data logging capabilities for analysis, and user-friendly interfaces for ease of operation.

1. Tensile Testing This function measures the force required to pull the cable until it breaks. The results indicate the cable's strength and durability, crucial factors in industrial applications.

2. Elongation and Stretch Tests These tests assess the flexibility of the cable under stress. Cables that exhibit excessive elongation may not perform adequately in scenarios where movement or bending is unavoidable.

3. Electrical Insulation Testing This feature ensures that the cable's insulation can withstand electrical loads without breaking down. Inadequate insulation can lead to electrical shocks, equipment damage, or fires.

cable winding test machine exporters

4. Data Analysis Many machines now offer sophisticated data analysis tools that help manufacturers interpret test results and make informed decisions regarding production adjustments and quality control measures.

The Role of Exporters in the Global Market

The global demand for advanced cable winding test machines has spurred a vibrant market for exporters. These companies play a pivotal role in connecting manufacturers with high-quality testing equipment from various regions. Exporters often maintain relationships with leading manufacturers of cable winding test machines, providing clients with an array of options that suit their specific needs.

1. Quality Assurance Exporters conduct rigorous assessments of the machines before they are shipped to ensure they meet international standards. This guarantees that end-users receive reliable and efficient testing equipment.

2. Market Expansion By exporting cable winding test machines, these companies help manufacturers in different countries access the latest technology, thus enabling them to enhance their testing processes and improve product quality.

3. Technical Support Many exporters provide ongoing technical support and training for their clients. This assistance is crucial in ensuring that manufacturers can operate the machines effectively and interpret test results accurately.

4. Customization Recognizing that different industries have varying needs, exporters often collaborate with manufacturers to offer customized solutions. This flexibility ensures that companies can find machines that meet their specific requirements, thus optimizing their testing processes.

Conclusion

The significance of cable winding test machines in the manufacturing sector cannot be overstated. These machines not only ensure compliance with industry standards but also enhance the overall quality and safety of the products. With the increasing globalization of trade, exporters play an essential role in facilitating access to cutting-edge technology for manufacturers worldwide. As the industry continues to grow, the demand for reliable testing equipment will remain at the forefront, driving innovation and ensuring that the cables powering our world are of the highest quality.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

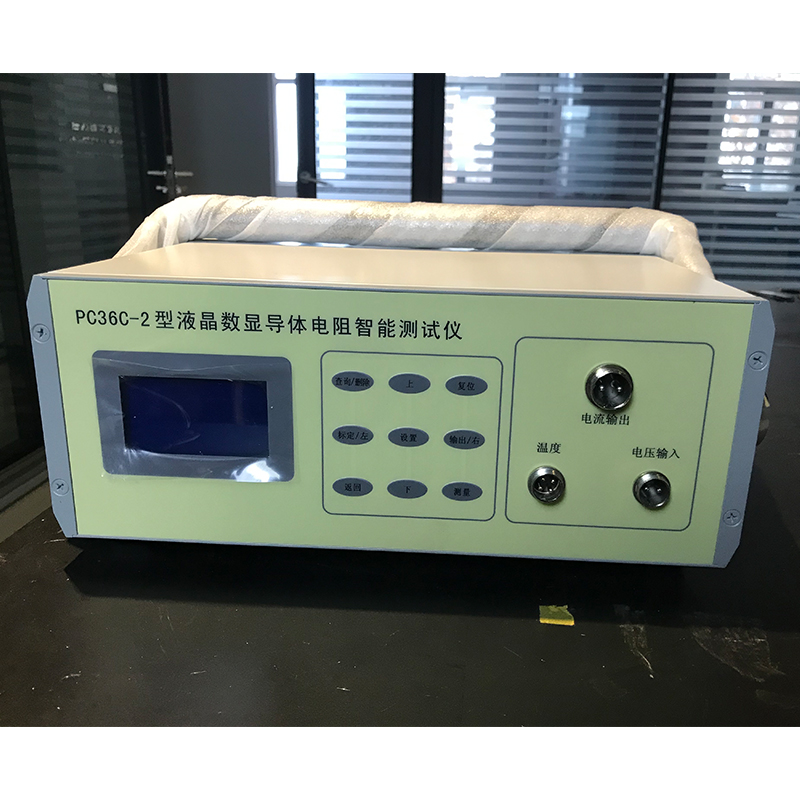

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy