Ene . 09, 2025 12:17

Back to list

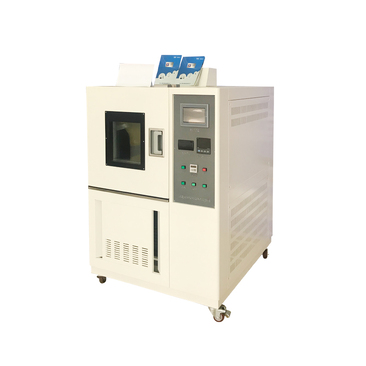

resistance tester

In the world of modern electrical engineering and maintenance, the resistance tester stands as an indispensable tool. Its profound significance stems from its ability to measure electrical resistance with precision, a parameter vital in assessing the condition and safety of electrical circuits and components. This article delves into the key aspects of resistance testers, emphasizing experiential insights, professional expertise, authoritative information, and trustworthiness in its evaluation of this critical instrument.

Authoritativeness in the context of resistance testers is established through adherence to industry standards and certifications. Leading manufacturers ensure their products comply with directives such as IEC 61010 for safety and ISO/IEC 17025 for calibration. These certifications affirm the product’s reliability and safety for professional use. It's crucial for technicians and engineers to choose devices that meet these standards to ensure accurate measurements and protect both the equipment and operators from hazards. Trustworthiness in resistance testers is built over time, through consistent performance and durability. Brands that have a track record of delivering quality products are often preferred in the market. User reviews and testimonials play a vital role in establishing a product's reputation. Feedback from seasoned professionals who have used a specific resistance tester model over extended periods provides invaluable insights into its long-term reliability. Moreover, after-sales service, including calibration support and warranty services, further enhances a brand's trustworthiness. In conclusion, the resistance tester is a cornerstone tool for any electrical professional. Its efficacy in safeguarding electrical systems cannot be overstated. By leveraging state-of-the-art technology, adhering to stringent standards, and building a strong reputation for reliability and safety, resistance testers continue to uphold their role as authoritative instruments in the field. Choosing the right resistance tester not only ensures compliance with industry norms but also fortifies the trust professionals place in their diagnostic equipment, ultimately leading to safer and more efficient electrical systems.

Authoritativeness in the context of resistance testers is established through adherence to industry standards and certifications. Leading manufacturers ensure their products comply with directives such as IEC 61010 for safety and ISO/IEC 17025 for calibration. These certifications affirm the product’s reliability and safety for professional use. It's crucial for technicians and engineers to choose devices that meet these standards to ensure accurate measurements and protect both the equipment and operators from hazards. Trustworthiness in resistance testers is built over time, through consistent performance and durability. Brands that have a track record of delivering quality products are often preferred in the market. User reviews and testimonials play a vital role in establishing a product's reputation. Feedback from seasoned professionals who have used a specific resistance tester model over extended periods provides invaluable insights into its long-term reliability. Moreover, after-sales service, including calibration support and warranty services, further enhances a brand's trustworthiness. In conclusion, the resistance tester is a cornerstone tool for any electrical professional. Its efficacy in safeguarding electrical systems cannot be overstated. By leveraging state-of-the-art technology, adhering to stringent standards, and building a strong reputation for reliability and safety, resistance testers continue to uphold their role as authoritative instruments in the field. Choosing the right resistance tester not only ensures compliance with industry norms but also fortifies the trust professionals place in their diagnostic equipment, ultimately leading to safer and more efficient electrical systems.

Latest news

-

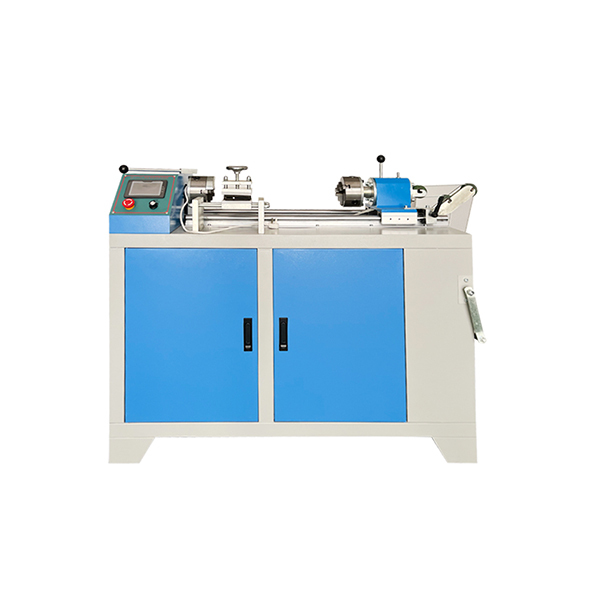

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy