Tensile Strength Testing Equipment Producers and Factories for Quality Assurance

Understanding Tensile Strength Tester Manufacturers A Factory Perspective

Tensile strength testing is a critical process across various industries, including materials science, engineering, and manufacturing. The ability to accurately measure how much force a material can withstand while being stretched or pulled until failure is paramount. This process is facilitated by tensile strength testers, sophisticated machines designed to assess the tensile properties of materials. In this article, we will explore the world of tensile strength tester manufacturers from a factory perspective, focusing on their significance, the manufacturing process, and the key considerations for choosing the right supplier.

The Importance of Tensile Strength Testing

Tensile strength tests are essential for ensuring that materials meet specific standards and quality requirements before they are used in production. Whether it’s metals, polymers, textiles, or composites, knowing the tensile strength of a material can prevent catastrophic failures in applications such as aerospace, automotive, and structural engineering. Manufacturers of tensile strength testers play a critical role in providing the equipment needed for these essential tests, which helps ensure product safety and reliability.

The Manufacturing Process

The production of tensile strength testers involves several meticulous steps to ensure precision and reliability. Factories typically start with design and engineering, where skilled professionals develop testing machines that adhere to international standards such as ASTM and ISO. These designs are then transferred to manufacturing, where various components—including load cells, grips, and software systems—are fabricated.

High-quality materials are paramount in the construction of tensile strength testers. Factories source materials based on the required specifications; for instance, the load cell must be made from durable materials that can withstand high levels of stress without deformation. Once the components are produced, they go through rigorous quality control processes to ensure they meet the required performance standards.

After assembly, the testing machines undergo calibration and extensive testing to confirm their accuracy. This step is crucial, as even minor deviations can lead to significant errors in tensile strength measurements. Once the machines pass all quality checks, they are shipped to customers, often accompanied by documentation certifying their performance.

Key Considerations for Choosing a Manufacturer

tensile strength tester manufacturers factory

Selecting the right tensile strength tester manufacturer is vital for businesses that require reliable and accurate testing equipment

. Here are some key considerations1. Quality Standards Check if the manufacturer adheres to recognized quality standards and certifications. This ensures that the machines produced are reliable and accurate.

2. Customization Options Different industries may have unique testing requirements. A good manufacturer should offer customization options to meet specific needs, such as varying load capacities or special grips for different materials.

3. Reputation and Experience Research the manufacturer's background, industry reputation, and years of experience. A well-established company with a solid track record is likely to provide better support and quality.

4. Customer Support and Service After-sales service is crucial. Consider manufacturers that offer comprehensive customer support, including training for operators, maintenance services, and quick response times for technical issues.

5. Price While cost is always a factor, it's important to balance price with quality and features. Cheaper machines may save initial costs but can lead to higher long-term expenses due to repairs and inconsistent results.

6. Innovative Technology The field of materials testing is constantly evolving. Manufacturers that invest in research and development to incorporate the latest technologies—such as automation, software integration, and advanced data analysis—will provide a competitive advantage.

Conclusion

Tensile strength tester manufacturers play an essential role in material testing processes that ensure safety and compliance with industry standards. Understanding the manufacturing process, the importance of selecting the right supplier, and the significance of quality assurance can aid organizations in making informed decisions. As industries continue to evolve, choosing a manufacturer committed to quality and innovation will ultimately contribute to better product performance and reliability in the market. By investing in the right tensile strength tester, companies can not only enhance their testing capabilities but also ensure the integrity of their end products.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

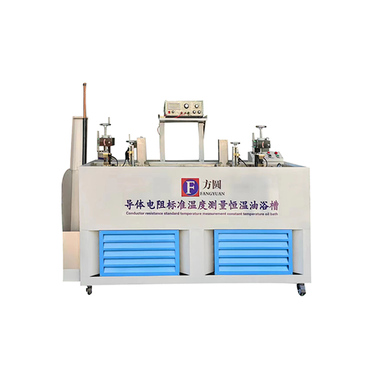

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy