dc insulation resistance tester manufacturer

Understanding DC Insulation Resistance Testers A Comprehensive Overview

In the realm of electrical engineering and maintenance, the importance of ensuring the integrity of insulation systems cannot be overstated. An essential tool for this purpose is the DC insulation resistance tester, a device specifically designed to measure the resistance of electrical insulation materials. This article delves into the significance of these testers, their features, and the role of manufacturers in this industry.

The Importance of Insulation Resistance Testing

Electrical insulation acts as a barrier that prevents unwanted current from leaking into unintended areas, which is crucial for the safety and efficiency of electrical systems. Over time, insulation can degrade due to factors like age, environmental conditions, and mechanical stress. Therefore, regularly testing the insulation resistance is vital to identify potential issues before they lead to catastrophic failures, electrical shocks, or fires.

Insulation resistance testing helps in assessing the condition of equipment, ensuring compliance with safety standards, and improving maintenance schedules. This preventive measure not only safeguards human life but also protects valuable equipment and reduces downtime.

Features of DC Insulation Resistance Testers

DC insulation resistance testers are specialized instruments that apply a direct current (DC) voltage to the insulation material and measure the resistance offered by it. Here are some key features that define these testers

1. Voltage Ranges Many testers come equipped with multiple voltage settings, commonly ranging from 250V to 5000V. This allows users to test various types of equipment according to their specific insulation requirements.

2. Resistance Measurement These testers typically provide readings in megohms (MΩ), which is essential for determining whether the insulation strength is within acceptable limits. Generally, values of 1 MΩ or higher are considered good, but this can vary by application.

3. Auto-Ranging and Manual Settings Advanced models feature auto-ranging capabilities, which automatically select the optimal measurement range, simplifying the testing process for users.

dc insulation resistance tester manufacturer

5. Safety Features Many reputable manufacturers build safety features into their testers, such as automatic disconnection of the test current upon detecting low resistance levels, thus protecting both the tester and the equipment being evaluated.

6. Durability and Portability Given the fieldwork often required in electrical maintenance, most insulation resistance testers are designed to be rugged and portable, able to withstand harsh working conditions.

Choosing the Right Manufacturer

When it comes to selecting a DC insulation resistance tester, the choice of manufacturer is critical. A reputable manufacturer will adhere to industry standards and provide reliable products that meet safety regulations. Here are some factors to consider

1. Experience and Reputation Established manufacturers with a long history in the industry are more likely to produce reliable and high-quality testers. Customer reviews and industry certifications can provide insight into the manufacturer's reputation.

2. Support and Service Consider manufacturers that offer comprehensive customer support, warranties, and service options. This assurance can prove invaluable, especially when dealing with technological issues or repairs.

3. Innovation and Technology The electrical testing industry continually evolves, with new technologies emerging regularly. Manufacturers that invest in research and development and incorporate the latest technology into their products often yield more efficient and accurate testing solutions.

4. Product Range A wide range of products may indicate a manufacturer's capability to cater to different sectors, such as industrial, commercial, and residential applications—all of which can require different testing specifications.

Conclusion

DC insulation resistance testers are indispensable tools for ensuring the safety and functionality of electrical systems. As technology advances, the quality and features of these testers will continue to improve. Choosing the right manufacturer is just as important as selecting the right tester, as it impacts the reliability and performance of the device you rely on for critical safety assessments. Investing in a high-quality insulation resistance tester not only ensures compliance with safety regulations but also plays a vital role in the longevity and efficiency of electrical systems.

-

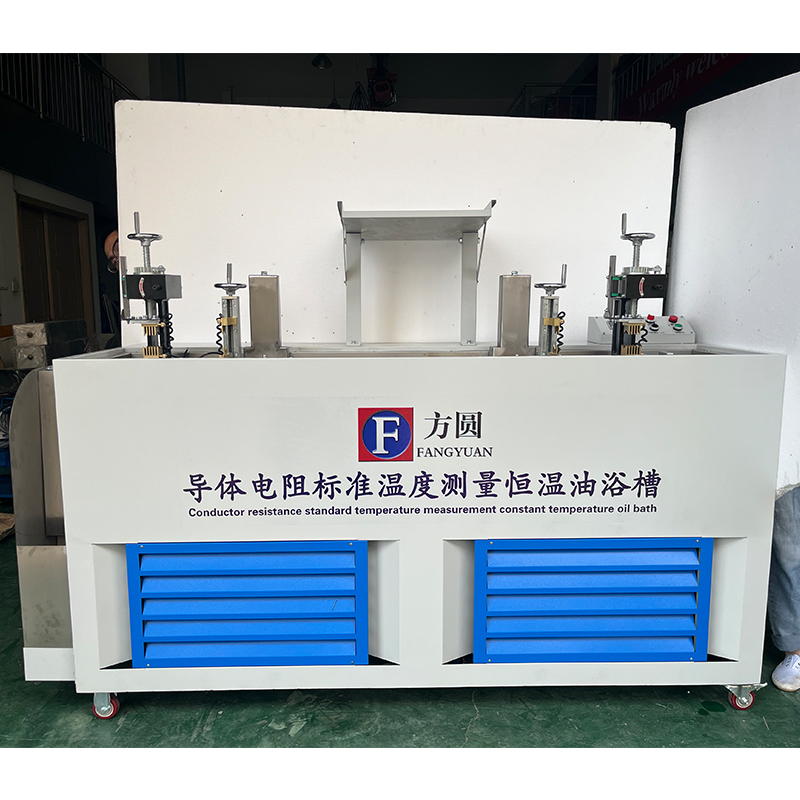

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy