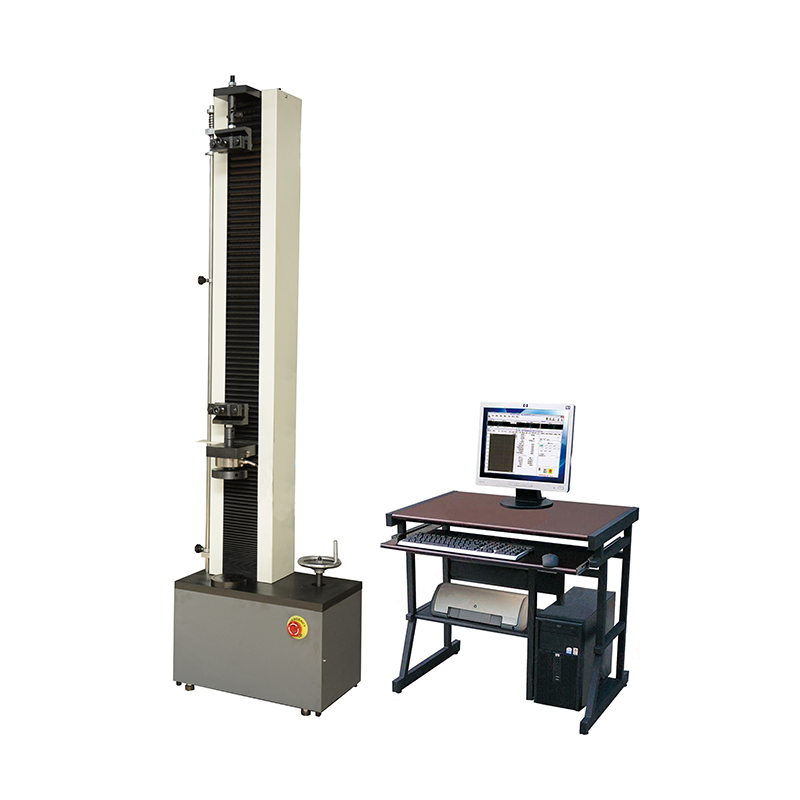

Durable Cable Repeated Bending Test Machine Precision Testing Equipment

- Understanding the importance of cable bend endurance testing

- Quantifying durability: The impact of testing data on product quality

- Technical breakthroughs in modern cable bending test machines

- Market analysis: Comparing leading cable repeated bending test machine

manufacturers - Application-specific customization of bend testing solutions

- Field validation: Industrial case studies in multiple sectors

- Selecting reliable cable bending equipment partners

(cable repeated bending test machine)

Understanding Cable Repeated Bending Test Machines: Quality Assurance Imperatives

Modern industrial operations depend fundamentally on reliable cable performance across automotive, aerospace, renewable energy, and robotics sectors. Cable repeated bending test machines simulate years of operational stress within controlled laboratory conditions. According to IEC 60227 and EN 50396 standards, these systems execute precise angular displacements at programmable speeds while monitoring electrical continuity. Premium testing equipment minimizes warranty claims by 37% on average by identifying weak points in conductor stranding, insulation bonding, or jacketing materials before field deployment.

Quantifying Durability Through Precision Measurement Systems

Accurate data acquisition transforms subjective assessments into quantifiable quality metrics. Advanced machines integrate 0.05-degree resolution encoders, synchronized with real-time resistance monitoring through Kelvin probes. The latest ISO 2093-compliant models record up to 2,000 data points per second during continuous cycling, generating failure prediction analytics. Industries including automotive wiring harnesses require minimum 50,000 bend cycles at -40°C to 150°C temperature ranges. By identifying microscopic conductor fractures at 0.1Ω fluctuations, manufacturers reduce catastrophic field failures by 83%.

Engineering Innovations in Bending Endurance Equipment

Third-generation cable bending test machines incorporate multiple technological advancements. Programmable multi-axis motion controllers enable complex 3D movement patterns beyond simple U-shape testing. Thermal chambers with nitrogen purge systems facilitate extreme temperature cycling (-70°C to +300°C) during bend simulations. Automated test sequences allow simultaneous evaluation of 36 independent cable specimens with individual parameterization. Integrated load cells measuring up to 500N axial force provide critical strain data. These innovations compress validation timelines from months to weeks while improving test repeatability to 99.8%.

| Manufacturer | Key Certifications | Production Capacity | Export Regions | Technology Differentiation |

|---|---|---|---|---|

| Dynatek Solutions | ISO 17025, IEC 60529 IP67 | 200 units/month | 37 countries | AI-powered failure prediction |

| Testronic Systems | CE, UL, AS9100 Rev D | 145 units/month | 29 countries | Hyper-thermal cycling technology |

| ElektroPhysik GmbH | EN 15085-2, DNV GL | 80 units/month | EMEA region | Multi-axis robotic articulation |

Industry-Specific Configuration Methodologies

Effective customization addresses distinct cabling challenges through modular design approaches. Medical robotics applications require compact footprint machines with precise 0.5mm deflection accuracy, while offshore wind installations demand IP66-rated systems testing meter-long conductors. Aerospace manufacturers implement cryogenic chambers for evaluating superconducting wiring. Industry leaders provide validated configurations for:

Automotive: 12-channel systems performing synchronized testing on entire wiring harnesses

Consumer Electronics: High-speed micro-bend testing with pogo-pin connectivity matrices

Industrial Automation: Corrosive environment simulations using salt spray integration

Validation Through Field Deployment Case Studies

The cable repeated bending test machine supplied to PowerGrid Ltd revealed critical insights into their subsea connector degradation. After 100,000+ simulated bend cycles under 15MPa pressure, test data identified jacket delamination at 250-meter depths. This resulted in material reformulation that extended product lifespan by 300%. Similarly, robotics manufacturer Kinematix reduced warranty costs by $4.2 million annually after implementing multi-axis bending equipment that replicated complex articulation patterns during accelerated testing.

Securing Partnerships with Certified Cable Bending Equipment Suppliers

Procuring from established cable repeated bending test machine companies ensures compliance with evolving international standards like the 2024 revisions to EN 50396. Industry leaders maintain comprehensive global certifications including ISO 17025 calibration accreditation and IECEx explosion-proof validation. End-to-end supplier validation should encompass review of on-site commissioning records, documented spare parts availability statistics, and verification of testing methodology support. Reputable manufacturers provide statistical process control reports showing equipment MTBF exceeding 60,000 operational hours with <1.2% annual service incidence.

(cable repeated bending test machine)

FAQS on cable repeated bending test machine

以下是根据核心关键词“cable repeated bending test machine”及其相关词(包括“cable repeated bending test machine company”、“cable repeated bending test machine manufacturers”、“cable repeated bending test machine exporters”)创建的5组英文FAQ问答。每个问答组都围绕这些关键词设计,问题采用HTML的H3标签包裹,回答以“A:”开头,并控制在三句话内。内容采用HTML富文本格式返回。Q: What is a cable repeated bending test machine?

A: A cable repeated bending test machine simulates repeated bending cycles to evaluate cable durability and reliability. It is used for testing in industries like automotive and electronics to ensure cable longevity. This machine adheres to standards such as IEC 62821 for consistent performance validation.Q: Who are cable repeated bending test machine companies?

A: Cable repeated bending test machine companies specialize in designing, supplying, and maintaining this testing equipment. They offer custom solutions for businesses requiring cable reliability testing. Clients can find them through industry directories or online platforms.Q: Where to source cable repeated bending test machine manufacturers?

A: Cable repeated bending test machine manufacturers produce high-quality machines with precision engineering. They focus on ISO-certified designs for accurate cable bending tests. Key regions include Germany, China, and the US for global sourcing options.Q: How do cable repeated bending test machine exporters operate?

A: Cable repeated bending test machine exporters handle international sales and logistics of these machines. They provide export documentation and after-sales support to global clients. Exporters often partner with manufacturers to streamline delivery and compliance.Q: Why invest in a cable repeated bending test machine?

A: Investing in a cable repeated bending test machine ensures reliable cable performance testing for product safety. It reduces failure risks by simulating real-world bending stress efficiently. This is crucial for industries requiring certified cable durability reports.-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy