Úno . 05, 2025 04:48

Back to list

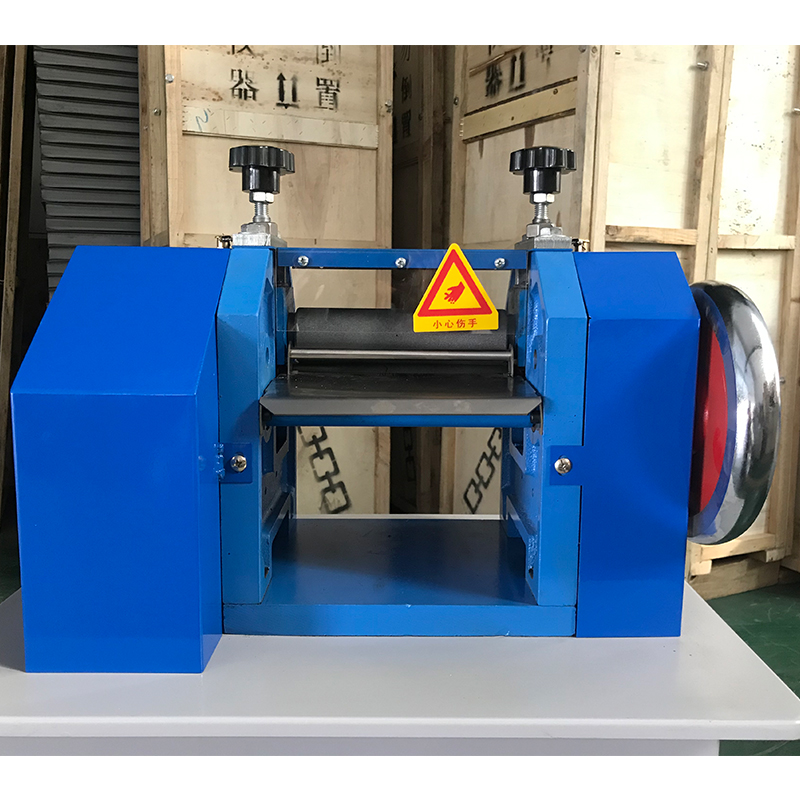

Wire and Cable Smoke Density Test Machine

In the precise and ever-evolving world of cable manufacturing and design, the introduction of custom measure machines for cables signifies a vital enhancement in both efficiency and precision. These machines are transforming the industry landscape by providing bespoke solutions tailored to specific production needs, thereby optimizing both performance and resource utilization.

Authoritativeness in the field comes from years of research and cumulative knowledge, which is why leading companies opting for custom measure machines often partner with industry leaders who have established themselves as pioneers in measurement technology. These collaborations guarantee that the machines are built on a foundation of innovation and reliability, integrating cutting-edge technology with proven performance standards. Trustworthiness is perhaps the most critical element, as the accuracy and efficiency of custom measurement machines directly impact product quality and business profitability. Manufacturers promoting these machines often provide extensive support services, including calibration, maintenance, and training to maximize machine utility and lifespan. This comprehensive service offering not only enhances machine performance but also builds a trusted relationship between supplier and manufacturer. By adopting these custom measurement solutions, cable manufacturers are poised to achieve significant reductions in waste and rework, leading to cost savings and faster time-to-market. The precision offered by these machines minimizes material usage and ensures compliance with international standards, enhancing the overall competitiveness of the end product. Additionally, this technology contributes to sustainable production practices. Precise measurement reduces material wastage and energy consumption, aligning with global efforts towards environmentally-friendly manufacturing processes. This alignment not only benefits the planet but also enhances the brand reputation of manufacturers committed to sustainable practices. In conclusion, custom measure machines for cables embody the future of cable manufacturing. Their integration into the production line represents a significant leap forward in technological application, driven by experience, expertise, authority, and trust. As industries increasingly prioritize quality, efficiency, and sustainability, the adoption of custom measurement solutions is not just beneficial but essential in maintaining a competitive edge in the global market.

Authoritativeness in the field comes from years of research and cumulative knowledge, which is why leading companies opting for custom measure machines often partner with industry leaders who have established themselves as pioneers in measurement technology. These collaborations guarantee that the machines are built on a foundation of innovation and reliability, integrating cutting-edge technology with proven performance standards. Trustworthiness is perhaps the most critical element, as the accuracy and efficiency of custom measurement machines directly impact product quality and business profitability. Manufacturers promoting these machines often provide extensive support services, including calibration, maintenance, and training to maximize machine utility and lifespan. This comprehensive service offering not only enhances machine performance but also builds a trusted relationship between supplier and manufacturer. By adopting these custom measurement solutions, cable manufacturers are poised to achieve significant reductions in waste and rework, leading to cost savings and faster time-to-market. The precision offered by these machines minimizes material usage and ensures compliance with international standards, enhancing the overall competitiveness of the end product. Additionally, this technology contributes to sustainable production practices. Precise measurement reduces material wastage and energy consumption, aligning with global efforts towards environmentally-friendly manufacturing processes. This alignment not only benefits the planet but also enhances the brand reputation of manufacturers committed to sustainable practices. In conclusion, custom measure machines for cables embody the future of cable manufacturing. Their integration into the production line represents a significant leap forward in technological application, driven by experience, expertise, authority, and trust. As industries increasingly prioritize quality, efficiency, and sustainability, the adoption of custom measurement solutions is not just beneficial but essential in maintaining a competitive edge in the global market.

Latest news

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy