Electrical Resistance Testing Device for Accurate Measurements and Diagnostics

Understanding Resistance Tester Electrical Devices A Comprehensive Overview

In today's world, electrical systems are integral to our daily lives, powering homes, industries, and technologies. Among the essential tools that ensure the safety and functionality of these systems is the resistance tester, commonly referred to as an electrical resistance tester or insulation resistance tester. This article will delve into the significance, operation, and application of resistance testers in the electrical domain.

The Importance of Resistance Testing

Electrical resistance testing is a crucial process in determining the integrity and safety of electrical insulation and components. The flow of electric current can be influenced by the resistance encountered, making it essential to measure resistance accurately. High resistance values in electrical components often indicate that the insulation materials are in optimal condition. Conversely, low resistance readings can point to potential faults, such as short circuits or insulation degradation, which could lead to equipment failure or pose safety hazards.

Types of Resistance Testers

Resistance testers come in various forms, each designed for specific applications within the electrical industry. The most common types include

1. Analog Ohmmeters These traditional devices utilize a needle to indicate resistance levels on a scale. While they are less common today due to the prevalence of digital tools, they are still useful for basic resistance measurements.

2. Digital Ohmmeters Offering improved accuracy and readability, digital ohmmeters provide numerical resistance values on a digital display. They often come equipped with features such as auto-ranging and data hold, making them user-friendly.

3. Insulation Resistance Testers Specifically designed for high-voltage insulation testing, these devices can apply a substantial voltage (typically 250V, 500V, or 1000V) to measure the electrical resistance of insulators. They are critical for testing cables, transformers, and other electrical equipment to ensure their insulation is adequate to prevent electrical failures.

4. Micro-ohmmeters These testers are used to measure very low resistance levels, typically in electrical connections or components. They are crucial for applications that demand precise measurements, such as measuring the resistance of circuit breakers and bonding connections.

How Resistance Testers Work

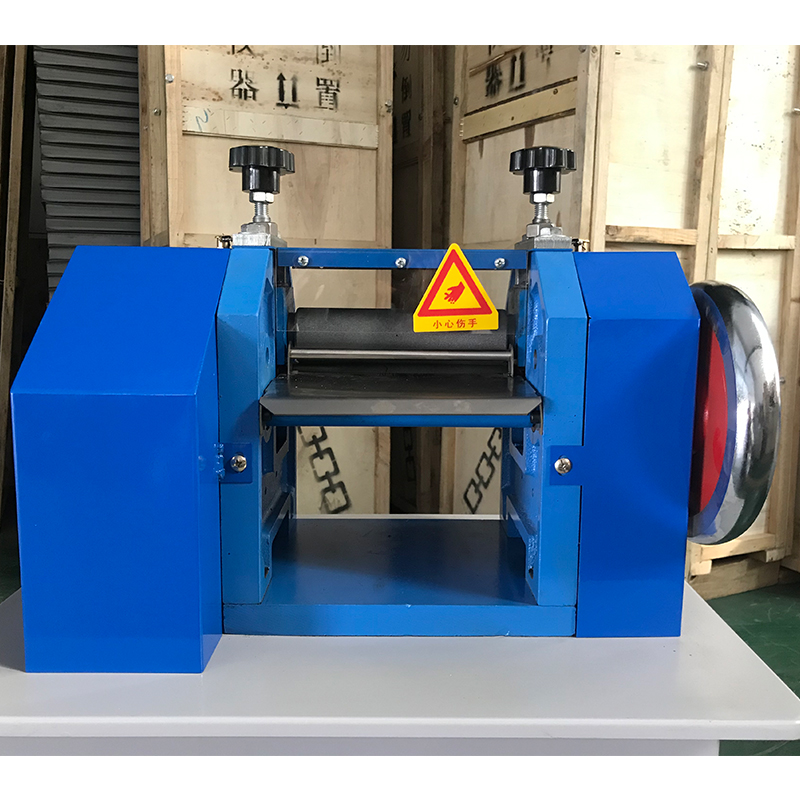

resistance tester electrical

Resistance testers function on Ohm's Law, which states that the resistance (R) of a conductor is equal to the voltage (V) divided by the current (I) flowing through it (R = V/I). Most resistance testers apply a known voltage across a component and measure the resulting current to calculate the resistance. This effective method allows for accurate assessments of the electrical characteristics of various materials and components.

For insulation resistance testing, the device applies a high voltage to the insulation while measuring the resulting leakage current. The resistance value is then calculated by the tester based on the applied voltage and measured current, helping to identify potential insulation failures.

Applications of Resistance Testers

Resistance testers are employed across numerous sectors, including

1. Electrical Maintenance Regular resistance testing helps identify issues before they escalate, minimizing downtime and repair costs.

2. Safety Inspections In industries where high voltage equipment is used, resistance testing ensures that insulation is intact, thereby safeguarding against electrical shock and equipment failures.

3. Construction and Installation Electricians use resistance testers to verify that newly installed wiring and components meet required safety standards.

4. Public Utilities Utility companies frequently use insulation resistance testers on power distribution networks to assess the health of their infrastructure.

5. Manufacturing In manufacturing settings, resistance testing ensures the reliability of electrical components used in machinery and production lines.

Conclusion

In summary, resistance testers are vital tools in maintaining the safety and efficiency of electrical systems. By providing critical insights into the resistance levels of electrical components and insulation, these devices help prevent electrical failures and enhance safety standards across various industries. As technology continues to evolve, the accuracy, portability, and features of resistance testers will undoubtedly improve, further solidifying their role in the electrical sector. Understanding and utilizing these tools effectively will be paramount for professionals aiming to ensure the integrity and reliability of electrical systems.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy