tensile strength of fabric tester factory

Understanding Tensile Strength Testing in Fabric Factories

Tensile strength is a critical property of textiles, underpinning their performance, durability, and usability across various applications. In the fabric manufacturing industry, assessing tensile strength is essential to ensure that products meet industry standards and consumer expectations. Fabric testers play a crucial role in this evaluation, enabling manufacturers to achieve quality assurance and competitive advantage.

Tensile strength refers to the maximum amount of tensile (pulling) stress that a material can withstand before failing or breaking. In the context of fabrics, this property is vital for determining how well a textile can endure stress and strain during usage. Various factors influence the tensile strength of fabrics, including the type of fibers used, the weave or knit structure, and the finishing processes applied post-production.

Fabric testers are specialized machines designed to measure the tensile strength of textiles. These testers typically operate under standardized conditions to ensure reliable and reproducible results. Two common methodologies employed in tensile testing are the ASTM D5034 and ISO 13934-1 standards, which provide guidelines on how the tests should be conducted, including sample preparation, testing speed, and data interpretation.

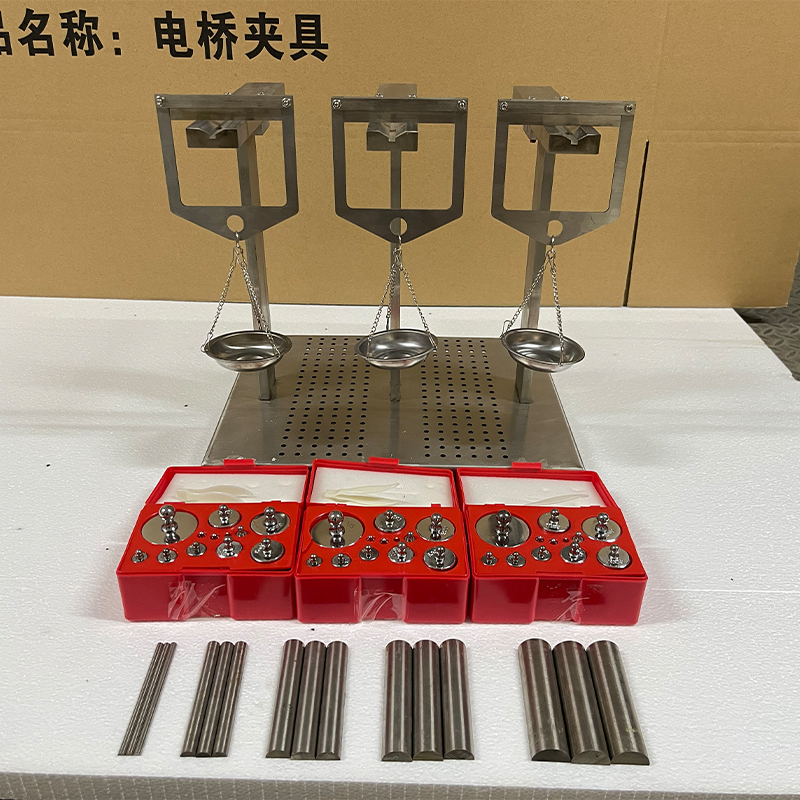

The primary components of a fabric tensile strength testing machine include grips, a load cell, and a control unit. The fabric sample is clamped securely between the grips, which then apply a force until the material reaches its breaking point. The load cell measures the force exerted on the fabric, and the control unit captures data that can be analyzed to demonstrate the fabric's performance characteristics.

tensile strength of fabric tester factory

In a typical testing scenario, a strip of fabric is cut to a specified width and length. The sample is mounted in the tensile tester, and the machine pulls the fabric at a constant speed. As the tester applies increasing force, the fabric elongates until it either fails or reaches a defined limit. The results document both the maximum load the fabric sustained and the elongation before breakage, both of which are crucial for characterizing the material.

For manufacturers, understanding the tensile strength of their fabrics not only helps guarantee product quality but also informs them about potential applications. For instance, fabrics with high tensile strength are suitable for heavy-duty applications, such as outdoor gear or industrial textiles, whereas lighter fabrics may be ideal for fashion garments. This knowledge enables designers and manufacturers to tailor products for specific markets, enhancing customer satisfaction and brand loyalty.

In addition to direct applications in manufacturing, tensile strength data is vital for compliance with safety standards and regulations. Failure to meet established tensile strength standards can lead to product recalls, liability claims, and damage to a brand’s reputation. Thus, a robust testing process not only highlights the strengths of a product but also identifies weaknesses that can be addressed through material selection or engineering changes.

As technology advances, fabric testing machines are becoming more sophisticated, incorporating data analytics and automation to improve accuracy and efficiency. Modern testers may offer integrated software for real-time data analysis, enabling manufacturers to quickly assess material properties and make adjustments to production processes as needed.

In conclusion, the tensile strength of fabrics is a vital metric that influences their performance in real-world applications. For fabric factories, investing in reliable tensile strength testing equipment is essential for product quality assurance, regulatory compliance, and market competitiveness. By understanding and utilizing tensile strength testing, manufacturers can not only enhance their products' reliability and safety but also drive innovation and growth in the textile industry. Through rigorous testing and quality control, fabric factories are better positioned to meet the evolving demands of consumers and capitalize on emerging market trends.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy