vertical profile projector exporter

The Vertical Profile Projector An Essential Tool for Precision Measurement

In the world of manufacturing and engineering, precision is paramount. One of the tools that have emerged as indispensable in achieving this precision is the vertical profile projector. This sophisticated piece of equipment is designed to magnify and project the outline of an object onto a screen for accurate measurement and analysis. Its applications span various industries, including aerospace, automotive, and metalworking, where the need for meticulous quality control is critical.

Understanding the Vertical Profile Projector

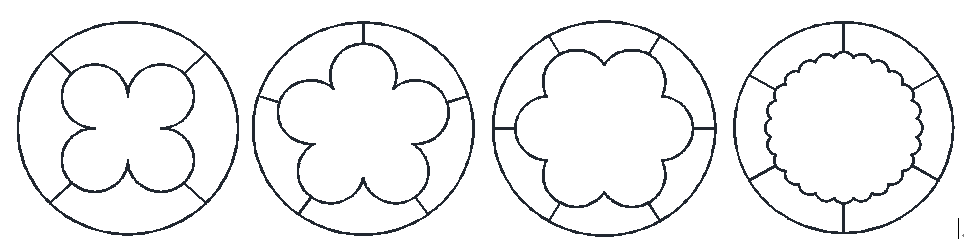

A vertical profile projector, often referred to as an optical comparator, uses a combination of optics and geometry to examine the profile of a workpiece. The device operates by illuminating the object from below with a focused light source. The projected shadow of the object is then cast onto a frosted glass screen or a digital display. This magnification allows engineers and inspectors to observe even the smallest details of the part, facilitating a better understanding of its dimensions and tolerances.

The design of a vertical profile projector typically includes a vertical stage where the workpiece is placed for measurement. The optical system includes lenses that can magnify the image up to several hundred times, depending on the model. Additionally, many modern projectors incorporate digital measurement tools, which can enhance the accuracy of readings and streamline the inspection process.

Advantages of Using Vertical Profile Projectors

One major advantage of vertical profile projectors is their ability to quickly and accurately measure complex geometries. Unlike traditional measuring tools, which may require multiple setups and calculations, optical comparators provide a comprehensive view of the part's profile in one go. This saves time and reduces the risk of human error during measurement.

vertical profile projector exporter

Another benefit is the enhanced visualization of features like radii, angles, and other intricate profiles. Inspectors can easily identify defects or deviations from specifications, allowing for timely corrections in the production process. Moreover, the non-contact nature of the measurement process means that even delicate parts can be measured without the risk of damage.

Applications in Industry

Vertical profile projectors are widely used in various sectors. In aerospace, for example, precision components such as turbine blades must meet stringent tolerances. Profile projectors help verify that parts conform to design specifications before they are integrated into critical systems. In the automotive industry, they are essential for inspecting engine components, ensuring that each part works flawlessly within the larger assembly.

Furthermore, these machines are valuable in educational settings, where they serve as teaching tools for engineering and mechanical students to understand the principles of measurement and geometry.

Conclusion

In conclusion, the vertical profile projector stands out as a crucial tool in the realm of precision measurement. Its ability to project detailed profiles onto screens fosters improved accuracy and efficiency in quality control across many industries. With ongoing advancements in technology, the functionality of these projectors continues to evolve, solidifying their position as a cornerstone in modern manufacturing and engineering practices. Investing in a vertical profile projector not only enhances measurement capabilities but also propels overall productivity and quality assurance in a highly competitive market.

-

reliable-performance-testing-with-advanced-aging-chamber-solutions

NewsAug.23,2025

-

advancing-precision-with-profile-projector-technology

NewsAug.23,2025

-

uv-led-ultraviolet-crosslinking-technology-innovation-and-prospects

NewsAug.23,2025

-

ensuring-safety-and-compliance

NewsAug.23,2025

-

electrical-properties-testing-in-modern-applications

NewsAug.23,2025

-

universal-tensile-testing-machine-applications-in-modern-electrical-and-material-testing

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy