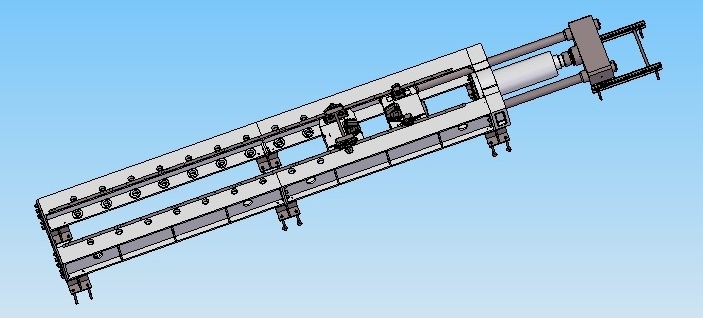

china electronic tensile strength tester

The Importance of Electronic Tensile Strength Testers in Modern Materials Testing

In today's fast-paced manufacturing and construction industries, the integrity and reliability of materials are paramount. One vital aspect of ensuring material quality is testing their tensile strength. Among the most effective tools for this purpose is the electronic tensile strength tester, a device that has revolutionized the way engineers and manufacturers assess materials.

Understanding Tensile Strength

Tensile strength refers to the maximum amount of tensile (pulling) stress that a material can withstand before failure. This property is essential for various materials, including metals, plastics, and textiles, as it directly affects their performance and safety in real-world applications. For instance, in construction, steel beams must possess a high tensile strength to support significant loads. Similarly, the tensile strength of fabrics is crucial in the garment industry, where durability and stretchability are critical factors.

The Role of Electronic Tensile Strength Testers

Electronic tensile strength testers provide precise and reliable measurements of tensile strength, offering significant advantages over traditional mechanical testers. These modern devices utilize electronic controls and advanced sensors, enabling them to measure stress and strain accurately during a tensile test.

One key advantage of electronic testers is their ability to conduct tests rapidly and with high levels of automation. Many models feature user-friendly interfaces that allow technicians to set parameters, initiate tests, and collect data seamlessly. This efficiency is crucial in today's manufacturing environments, where time is often directly related to profitability.

china electronic tensile strength tester

Moreover, electronic tensile strength testers typically provide real-time data analysis, which allows for immediate feedback on the material's performance

. This capability is invaluable for manufacturers, as it enables them to identify any anomalies or weaknesses in their materials quickly, facilitating timely adjustments to production processes.Applications Across Industries

The applications of electronic tensile strength testers are extensive and varied. In the automotive sector, for instance, manufacturers rely on these machines to test the strength of materials used in vehicle construction, ensuring safety and durability. In aerospace, where material failure can have catastrophic consequences, electronic tensile strength testers are essential for evaluating the strength of components used in aircraft and spacecraft.

Additionally, in the textile industry, these testers help manufacturers ensure that fabrics will perform well under stress, meeting customer expectations for quality and longevity. The pharmaceutical sector also employs tensile testing for packaging materials, ensuring that they can withstand environmental conditions and maintain product integrity.

Conclusion

As industries worldwide push for higher standards of quality and safety, the electronic tensile strength tester stands out as an indispensable tool. With its ability to provide accurate, real-time data and to streamline the testing process, this technology enhances material verification procedures across various fields.

Furthermore, with advancements in technology, the future of electronic tensile strength testing continues to evolve, promising even greater accuracy and efficiency. As manufacturers increasingly prioritize quality assurance, the role of these testers will undoubtedly become even more critical in ensuring that materials meet the demanding standards of modern applications.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy