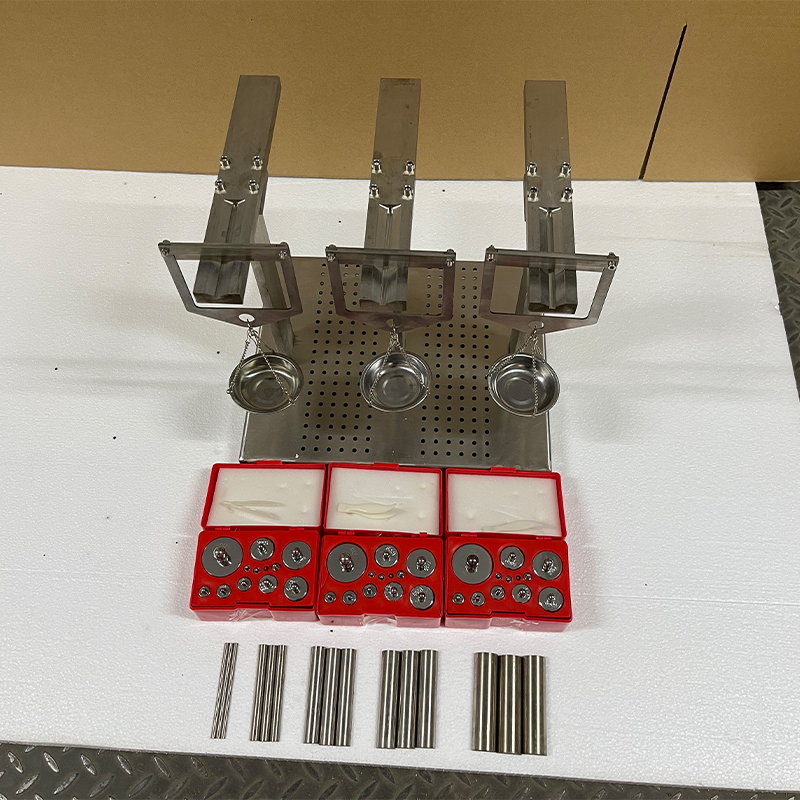

Custom Testing Equipment for Measuring Conductor Resistance in Electrical Systems and Applications

Understanding Conductor Resistance Test Fixture Factories

In the world of electrical engineering and manufacturing, the importance of quality testing cannot be understated. Among various testing procedures, the conductor resistance test plays a critical role in ensuring the reliability and efficiency of electrical components. This article explores the pivotal role of conductor resistance test fixture factories in producing tools essential for this testing process.

What is Conductor Resistance Testing?

Conductor resistance testing is a method used to measure the resistance of electrical conductors. This test helps in determining a conductor's efficiency, integrity, and reliability, which are essential for safe and optimal electrical performance. High resistance in a conductor can lead to overheating, energy loss, and potential system failures. Thus, ensuring low resistance within conductors is crucial for the performance of electrical systems, particularly in power distribution, telecommunications, and various industrial applications.

The Role of Test Fixtures

Test fixtures are specialized instruments designed to hold and connect electrical components securely during testing. They provide the necessary interface between the measuring instruments and the conductors under test, ensuring accurate and repeatable measurements. A well-designed test fixture will minimize external influences, such as stray resistance or temperature fluctuations, allowing for precise data collection.

The Conductor Resistance Test Fixture Factory

Conductor resistance test fixture factories specialize in designing and manufacturing these critical testing instruments. The process involves several key steps

1. Design and Engineering Engineers at these factories focus on creating test fixtures that can accommodate various conductor sizes and specifications. They utilize advanced design software and simulation tools to optimize the fixture layout, ensuring efficient performance.

conductor resistance test fixture factory

2. Material Selection The choice of materials is paramount in the manufacturing of test fixtures. High-quality metals with low resistivity, such as copper or aluminum, are often used to minimize any additional resistance that could skew test results. The durability and heat resistance of materials are also considered to enhance the longevity of the fixtures.

3. Manufacturing Process Factory production often involves modern manufacturing techniques, including CNC machining, injection molding, and 3D printing. These methods ensure precision and consistency in the production of test fixtures, adhering to strict industry standards.

4. Quality Control Rigorous quality control procedures are essential in test fixture manufacturing. Each fixture must undergo thorough testing to ensure it meets specified electrical and mechanical criteria. This ensures reliability and accuracy in the testing outcomes.

5. Customization Many conductor resistance test fixture factories offer customization options for clients. Depending on specific needs, they can tailor fixtures to accommodate unique configurations, connector types, or additional features like temperature measurement capabilities.

Importance of Test Fixture Factories

The significance of conductor resistance test fixture factories goes beyond mere manufacturing. They play an integral role in enhancing the safety and effectiveness of electrical systems. By providing high-quality testing tools, these factories help manufacturers and electricians ensure that their products meet required standards, thereby reducing the risk of failures in the field.

As industries continue to evolve with technology, the demand for reliable testing tools will only increase. The future of conductor resistance test fixture factories looks promising, with opportunities for innovation and improvement in testing methodologies, materials, and designs.

Conclusion

Conductor resistance test fixtures are vital for ensuring the integrity and performance of electrical conductors. Test fixture factories serve as the backbone of this testing process, producing high-quality, reliable equipment that meets the demands of modern electrical engineering. As technology advances, the role of these factories will continue to grow, highlighting their importance in the safe and effective operation of electrical systems worldwide.

-

High-Precision Digital Profile Projector for Advanced Measurement

NewsApr.10,2025

-

High-Precision Tensile Testing Machine for Reliable Material Strength Analysis

NewsApr.10,2025

-

High-Precision Resistance Tester for Accurate Electrical Measurements

NewsApr.10,2025

-

Enhance Accuracy with a High-Precision Resistance Measurement Fixture

NewsApr.10,2025

-

Advanced Cable Crosslinking Equipment for High-Performance Cable Manufacturing

NewsApr.10,2025

-

Advanced Cable Combustion Testing Machine for Reliable Fire Safety Assessment

NewsApr.10,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy