Hydraulic Conductor Resistance Testing Equipment Manufacturing Solutions and Innovations

Understanding Hydraulic Conductor Resistance Fixtures

In the realm of hydraulic systems, the efficiency and effectiveness of fluid transport and management are paramount. A key component in ensuring optimal performance of these systems is the hydraulic conductor resistance fixture. This device is designed to measure and analyze the resistance of hydraulic conductors, which includes pipes, hoses, and tubes used to transport fluids. Understanding its importance, functionality, and manufacturing process is essential for engineers and technicians involved in fluid dynamics and hydraulic systems.

Importance of Hydraulic Conductor Resistance

Hydraulic conductors often face variations in pressure, temperature, and flow rate, which can affect their overall performance. Resistance within these systems can lead to inefficiencies and potential system failures. Therefore, measuring the hydraulic conductor resistance is crucial in determining the suitability of a conductor for a particular application. This ensures that the hydraulic system operates within its designated parameters, thereby enhancing safety and reliability.

Functionality of Resistance Fixtures

Hydraulic conductor resistance fixtures play a vital role in evaluating the performance of these systems. These fixtures are engineered to simulate operational conditions under which a hydraulic conductor will function. By introducing measured variables such as fluid viscosity, temperature, and flow rate, these fixtures can accurately measure the resistance experienced by the fluid as it passes through various conductors.

The test procedure typically involves connecting the hydraulic conductor to the resistance fixture, followed by monitoring flow characteristics and the resistance encountered. Parameters are recorded, allowing engineers to analyze the performance characteristics of the conductor and identify any potential issues such as leaks or blockages.

Manufacturing Process of Resistance Fixtures

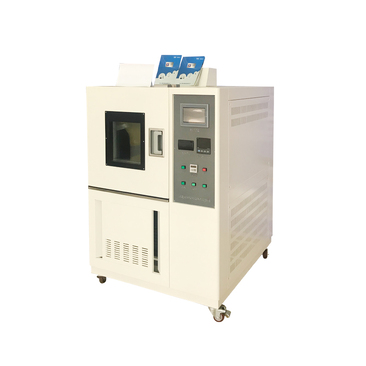

hydraulic conductor resistance fixture factory

The manufacturing of hydraulic conductor resistance fixtures involves a meticulous process to ensure precision and reliability. Factories producing these fixtures employ advanced technologies and materials to create durable and accurate instrumentation.

1. Material Selection High-quality materials that can withstand high pressures and corrosive fluids are chosen. Commonly used materials include stainless steel and high-strength polymers.

2. Precision Engineering Using computer-aided design (CAD) software, engineers design the fixtures to incorporate various sensors and measurement tools. This allows for real-time data acquisition and analysis during testing.

3. Fabrication Advanced manufacturing techniques such as CNC machining are then employed to create the components with high precision. This step ensures that the dimensions are exact, which is critical for accurate resistance measurements.

4. Assembly and Calibration Once the components are fabricated, they are assembled into the complete fixture. After assembly, the fixtures go through a rigorous calibration process to ensure that they produce accurate and consistent results during testing.

5. Quality Control Finally, manufacturers implement strict quality control measures to guarantee that each fixture meets industry standards and performs reliably in diverse testing scenarios.

Conclusion

In summary, hydraulic conductor resistance fixtures are essential tools in the evaluation and maintenance of hydraulic systems. By providing accurate measurements of resistance, these fixtures ensure that the hydraulic conductors can perform effectively under varying conditions. The meticulous manufacturing process guarantees their precision and reliability, making them indispensable in the engineering and maintenance of hydraulic systems. As technology continues to advance, these fixtures will undoubtedly evolve, further enhancing their capabilities and contributing to safer and more efficient hydraulic operations.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy