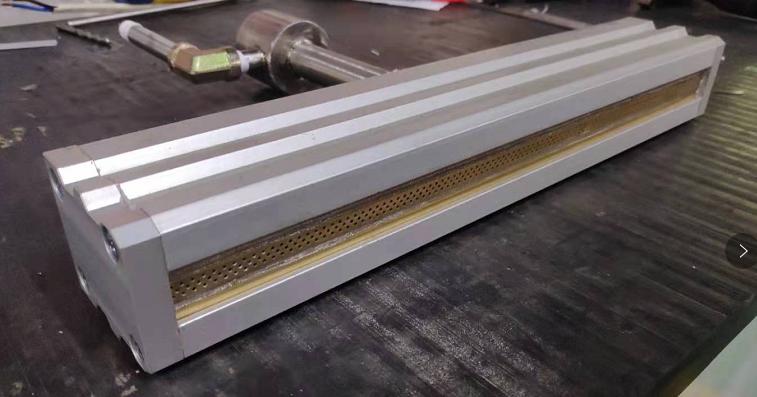

resistance measurement clamp factory

Resistance Measurement Clamp A Comprehensive Guide for Factories

In the realm of industrial manufacturing and quality control, precision and accuracy are paramount. One of the essential tools used in various applications is the resistance measurement clamp. These clamps are designed to measure the resistance of electrical components and systems, ensuring that they operate within specified parameters. This article will explore the significance, functionality, and benefits of resistance measurement clamps in factory settings.

Understanding Resistance Measurement

Resistance is a fundamental electrical property that quantifies how much a material opposes the flow of electric current. High-quality and reliable measurements are crucial in manufacturing processes, especially when dealing with electronic components, motors, or any equipment reliant on electrical functionality. Resistance measurement clamps provide a convenient and efficient means to assess this property without needing direct contact with the component under test.

How Resistance Measurement Clamps Work

Resistance measurement clamps typically utilize a principle known as Ohm's Law, which states that the current flowing through a conductor between two points is directly proportional to the voltage across the two points (V = IR). By measuring the voltage and current, the clamp can compute the resistance.

Most modern clamps employ advanced sensor technology to ensure maximum accuracy. They can be easily clamped around wires or terminals, allowing for non-intrusive measurements. This feature is particularly beneficial in a factory environment where numerous components are interconnected.

Benefits of Using Resistance Measurement Clamps in Factories

1. Non-Contact Measurement One of the most significant advantages of resistance measurement clamps is their non-contact measurement capability. This means that technicians can measure resistance without interrupting the electrical circuit, thereby minimizing downtime and potential disruption to production processes.

resistance measurement clamp factory

2. Portability and Ease of Use These clamps are generally lightweight and designed for easy handling, making them highly portable. Factory environments can vary, so having a reliable tool that can be carried around is essential for maintenance teams. Additionally, user-friendly interfaces on many models simplify operations, allowing quick training for staff.

3. Real-Time Monitoring Resistance measurement clamps can provide real-time data, enabling immediate detection of faults or inefficiencies in electrical systems. By monitoring resistance regularly, factories can preemptively address potential issues, reducing the risk of electrical failures that could lead to costly downtimes.

4. Improved Safety Electrical work can be hazardous, especially when working with high-voltage systems. Resistance measurement clamps minimize the need for direct contact with live wires, thus enhancing the safety of workers. With proper training and utilization, these tools can significantly reduce electrical accidents and injuries.

5. Enhancing Quality Control For factories that rely on electronic components, maintaining the correct resistance levels is crucial for overall product quality. Resistance measurement clamps aid quality control teams in ensuring that all components meet predetermined specifications, thus enhancing the reliability of the final products.

6. Cost Efficiency By streamlining maintenance processes and reducing downtime through quick diagnostics, resistance measurement clamps can lead to significant cost savings for factories. Additionally, using accurate resistance measurements can prolong the lifespan of electrical components, further saving money on replacements and repairs.

Choosing the Right Clamp

When selecting a resistance measurement clamp for factory use, several factors should be considered. Firstly, the measurement range and accuracy are critical, as different applications will require different specifications. Secondly, the clamp's ease of use and portability should align with the operational needs of the factory. Additionally, features like data logging, connectivity options (e.g., Bluetooth or USB), and additional measurement capabilities can enhance flexibility and functionality.

Conclusion

Resistance measurement clamps play a vital role in modern factory operations, providing essential measurements that uphold quality and efficiency. By integrating these devices into routine maintenance and quality control processes, factories can enhance productivity, improve safety, and ensure the longevity of their electrical systems. As technology continues to evolve, the capabilities of resistance measurement clamps will also expand, offering even greater benefits to manufacturers worldwide. Ensuring that the right tools are in place is an investment that pays dividends in the form of safety, reliability, and operational excellence.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy