Universal Testing Equipment for Material Strength and Durability Assessment

Understanding Universal Testing Machines A Key to Material Testing and Quality Assurance

Universal Testing Machines (UTMs) are essential instruments used in the field of materials science and engineering. These machines serve a crucial role in determining the mechanical properties of various materials, including metals, plastics, ceramics, and composites. By simulating different types of stresses – such as tension, compression, and shear – UTMs provide valuable data that informs engineers, researchers, and manufacturers about material behavior under varying conditions.

What is a Universal Testing Machine?

A Universal Testing Machine is a versatile and sophisticated device that can perform a range of tests on materials. The basic structure of a UTM consists of a loading frame, a testing platform, and a system for applying and measuring forces. The loading frame houses the necessary components to create tension or compression, while the testing platform holds the material specimen in place. Advanced models are equipped with digital displays and software that provide real-time data analysis and reporting.

Functionality and Types of Tests

UTMs can conduct various tests, including tensile strength, compressive strength, shear strength, flexural strength, and elongation tests. Tensile strength tests evaluate how materials behave when pulled apart; compressive strength tests measure resistance to crushing forces. Shear strength tests assess a material's ability to withstand sliding forces, while flexural strength tests examine how materials bend under stress.

The versatility of UTMs allows for comprehensive testing that adheres to international standards such as ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization). This adherence guarantees that the results are quality-assured and can be reliably compared across different tests and materials.

Applications Across Industries

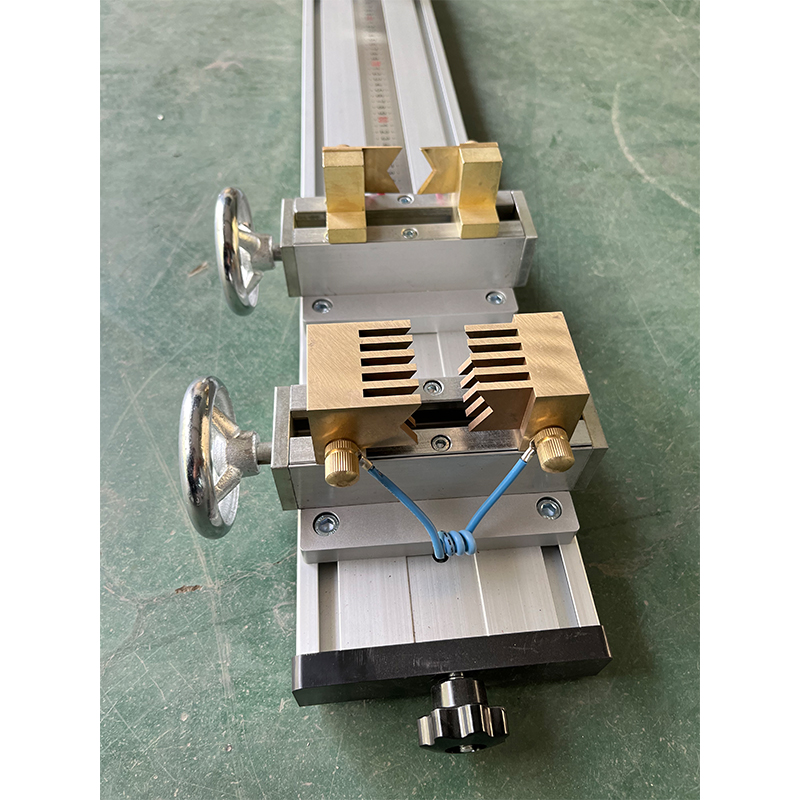

universal testing machine

The applications of Universal Testing Machines span numerous industries, including construction, manufacturing, aerospace, and automotive. In construction, for instance, the strength of materials like concrete and steel is paramount to ensuring structural safety and durability. In the automotive industry, the performance of vehicle components must be scrutinized to enhance safety and efficiency. Similarly, aerospace manufacturers utilize UTMs to test materials used in aircraft, where performance standards are exceptionally high.

Moreover, the medical field employs UTMs to evaluate materials used in implants and prosthetics, ensuring they can withstand bodily forces and remain safe for long-term use. The effective use of Universal Testing Machines underscores the importance of accurate material testing, which is fundamental to innovation and product development across various sectors.

The Importance of Accuracy and Reliability

The accuracy and reliability of Universal Testing Machines are critical in producing trustworthy data. Factors such as machine calibration, specimen preparation, and environmental conditions must be carefully controlled to ensure reliable results. Regular maintenance and updates to the testing software are necessary to keep up with technological advances and regulatory changes in testing procedures.

Moreover, the integration of automation and data analysis technologies in modern UTMs has enhanced their capabilities. The use of computer algorithms and machine learning can facilitate predictive modeling, allowing engineers to simulate how materials may behave under various conditions even before physical tests are conducted.

Conclusion

In conclusion, Universal Testing Machines are an indispensable tool in material testing and quality assurance. Their ability to assess a variety of mechanical properties provides vital insights that inform design, manufacturing, and compliance processes across industries. As technology advances, the role of UTMs will continue to evolve, further enhancing their accuracy and efficiency. Continued investment in this testing technology will ensure that materials meet the ever-increasing demands of modern applications and contribute to the safety and reliability of products we use daily.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy