Suppliers of DIY Tensile Strength Testing Equipment for Quality Assessment

Exploring Homemade Tensile Strength Testers A Guide to Suppliers and Materials

In the realm of materials science and engineering, understanding the tensile strength of materials is crucial for ensuring the safety and viability of various applications. Whether you're a DIY enthusiast, an engineering student, or a professional seeking budget-friendly testing methods, a homemade tensile strength tester can be an appealing project. Not only does it provide practical knowledge, but it also encourages innovation and resourcefulness. In this article, we will explore how to find suppliers for materials needed to create your own tensile strength tester while also discussing the significance of such devices.

Why Build a Homemade Tensile Strength Tester?

Traditional commercial tensile testing machines can be prohibitively expensive, especially for small businesses, educational institutions, or individual DIYers. By constructing your own tensile strength tester, you can cut costs while gaining hands-on experience in materials testing. A homemade tester allows you to customize the setup according to your specific needs and materials, providing a tailored solution for your testing requirements.

Key Components of a Tensile Strength Tester

Before diving into sourcing materials, let's outline the essential components required to build a basic tensile strength tester

1. Frame A robust frame is crucial for holding the test specimen and withstanding high forces. This can be made from materials like aluminum extrusions or steel tubing.

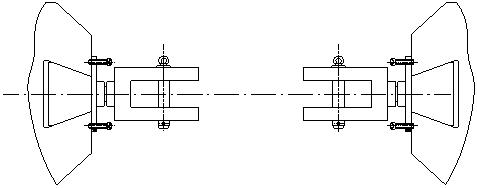

2. Grips These are used to hold the specimen securely in place. You can create simple grips using clamps, but more advanced designs may utilize machined parts to ensure uniform force application.

3. Load Cell This is a critical component that measures the force applied to the specimen. Load cells can be purchased from specialized suppliers or salvaged from other devices, such as electronic scales.

4. Displacement Measuring Device To measure how much the material elongates during the testing, a dial indicator, linear encoder, or even a smartphone app can be employed.

Sourcing Materials and Components

homemade tensile strength tester suppliers

Finding quality suppliers for the materials needed to construct your tensile strength tester is an integral part of the process. Here are some avenues to explore

1. Local Hardware Stores For basic components like the frame and grips, your local hardware store can be invaluable. They typically stock various materials ranging from steel and aluminum to bolts and fasteners.

2. Industrial Supply Companies Websites like McMaster-Carr and Grainger offer a vast selection of industrial components, including load cells and other electronic parts.

3. Electronics Suppliers For components like sensors and data acquisition systems, consider suppliers such as Digi-Key, Mouser, or even Amazon. They often carry load cells and related electronics at competitive prices.

4. Online Marketplaces Platforms like eBay and Alibaba can provide access to a wide range of tools and components, sometimes at significant discounts. However, ensure you verify the quality and reliability of the products before purchasing.

5. Local Universities and Maker Spaces If you have access to a local university or maker space, they may have resources for you to borrow or even workshops to help you construct your tester. Networking with engineering students or faculty can also yield tips on sourcing materials.

Building and Testing

Once you have sourced all your materials, it's time to start building. Following a well-structured plan or tutorial can significantly ease the process. Taking detailed notes during the construction phase can also be beneficial for troubleshooting any issues that arise.

After assembling your tensile strength tester, conduct preliminary tests to ensure its accuracy and reliability. Calibration using known weights will help establish a trustworthy baseline for your testing.

Conclusion

Creating a homemade tensile strength tester can be a rewarding project that enhances your understanding of materials' properties while saving costs. By sourcing materials from various suppliers and leveraging community resources, you can build an effective testing machine tailored to your needs. Through diligence and creativity, this venture not only promotes hands-on experience but also deepens your appreciation for the sciences behind material strength and engineering.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy