Precision Resistance Fixture for Accurate Testing and Calibration

Understanding Resistance Fixture A Key Component in Electrical Testing

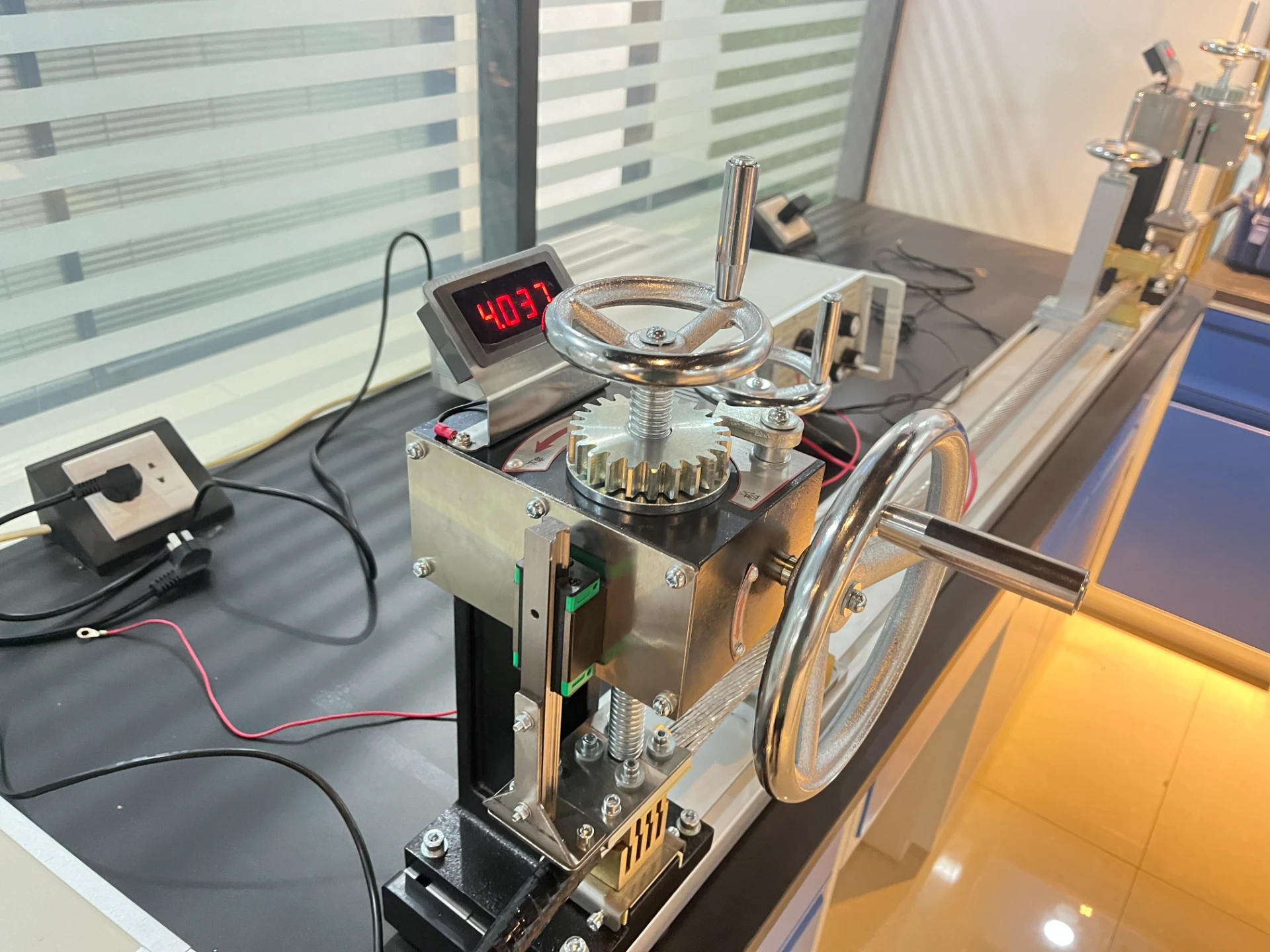

In the realm of electrical engineering and testing, precision is paramount. One of the critical tools utilized by engineers and technicians to ensure reliable performance and safety in electrical circuits is the resistance fixture. This specialized equipment allows for the accurate measurement of resistance in various components, ensuring that circuits function as intended and meet regulatory standards.

A resistance fixture is typically designed to facilitate the connection of a test device to the component whose resistance is being measured. The fixture provides stable and repeatable conditions for testing, which is essential for obtaining reliable data. The importance of this tool cannot be overstated, especially in industries where even minor variations in resistance can lead to significant performance issues.

The construction of a resistance fixture often includes high-quality connectors and conductors that minimize the introduction of extraneous resistance into the measurements

. This is crucial because any additional resistance introduced by the fixture itself can skew the results, leading to inaccurate assessments. Therefore, engineers must select fixtures that are designed for the specific type of tests they intend to conduct, ensuring compatibility with the components being measured.resistance fixture

One common application of resistance fixtures is in the testing of electrical resistors and sensors. These components are used in myriad applications, from simple household electronics to complex industrial machinery. By employing a resistance fixture, technicians can quickly establish whether these components are performing within their specified limits. This is essential not only for quality control during manufacturing but also for maintenance and troubleshooting in ongoing operations.

Moreover, resistance fixtures are integral to the testing protocols that ensure compliance with safety standards. In fields such as automotive, aerospace, and medical device manufacturing, adhering to strict regulations is non-negotiable. Utilizing resistance fixtures helps manufacturers demonstrate that their products meet necessary safety criteria, providing peace of mind for both producers and consumers.

As technology advances, so too do the designs and functionalities of resistance fixtures. Modern fixtures may integrate digital interfaces that facilitate real-time data collection and analysis. This not only enhances efficiency but also allows engineers to gain deeper insights into the performance characteristics of the components being tested. Additional features may include temperature control elements, which are crucial for tests that require specific environmental conditions.

In conclusion, the resistance fixture is a vital instrument in the field of electrical testing. Its ability to provide accurate, reliable, and repeatable measurements of resistance makes it indispensable for engineers and technicians alike. As industries strive for higher quality and enhanced safety measures, the importance of precise measurement tools like resistance fixtures will only continue to grow. Whether in the development of new technologies or the maintenance of existing ones, these fixtures play a pivotal role in ensuring that electrical components function correctly and safely.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy