jan . 09, 2025 13:58

Back to list

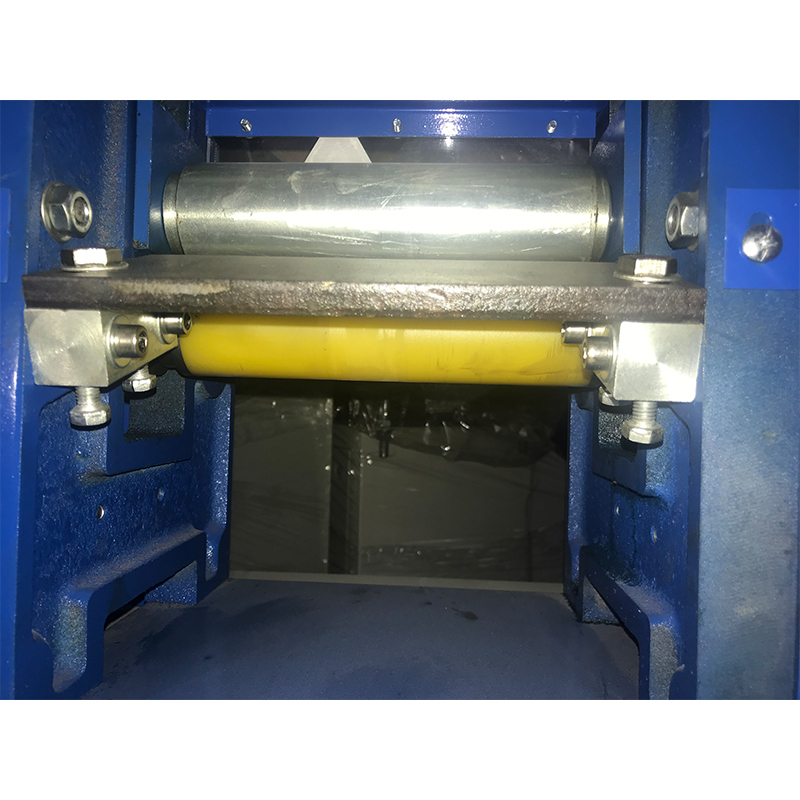

wire and cable testing machine

Selecting the right wire and cable testing machine is pivotal for ensuring product quality and performance in any manufacturing operation that deals with electrical components. These machines not only verify compliance with industry standards but also safeguard the integrity of cables that form the nervous system of electrical devices.

When it comes to authoritativeness, leading manufacturers of wire and cable testing machines often undergo rigorous third-party evaluations and certifications. Machines that have been certified by international bodies such as the International Electrotechnical Commission (IEC) or Underwriters Laboratories (UL) are generally considered more reliable and adhere to global safety and quality standards. As a trusted industry voice, it's crucial to recommend products that have received such validations, as they not only promise unparalleled performance but also inspire confidence among stakeholders. Trustworthiness is another fundamental pillar when navigating through the wire and cable testing landscape. Opt for manufacturers and suppliers with a longstanding reputation for quality. Testimonials from established industry partners and consistent positive feedback enhance trustworthiness, as do transparent service agreements and robust customer support systems. When issues arise, a dependable warranty and prompt servicing can save invaluable production time, substantiating the trust placed in these machines. In conclusion, wire and cable testing machines are indispensable assets in guaranteeing that your products meet the highest standards of quality and safety. By focusing on the experience, expertise, authoritativeness, and trustworthiness of these machines, businesses can not only ensure compliance but also fortify their reputation in the competitive market.

When it comes to authoritativeness, leading manufacturers of wire and cable testing machines often undergo rigorous third-party evaluations and certifications. Machines that have been certified by international bodies such as the International Electrotechnical Commission (IEC) or Underwriters Laboratories (UL) are generally considered more reliable and adhere to global safety and quality standards. As a trusted industry voice, it's crucial to recommend products that have received such validations, as they not only promise unparalleled performance but also inspire confidence among stakeholders. Trustworthiness is another fundamental pillar when navigating through the wire and cable testing landscape. Opt for manufacturers and suppliers with a longstanding reputation for quality. Testimonials from established industry partners and consistent positive feedback enhance trustworthiness, as do transparent service agreements and robust customer support systems. When issues arise, a dependable warranty and prompt servicing can save invaluable production time, substantiating the trust placed in these machines. In conclusion, wire and cable testing machines are indispensable assets in guaranteeing that your products meet the highest standards of quality and safety. By focusing on the experience, expertise, authoritativeness, and trustworthiness of these machines, businesses can not only ensure compliance but also fortify their reputation in the competitive market.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy