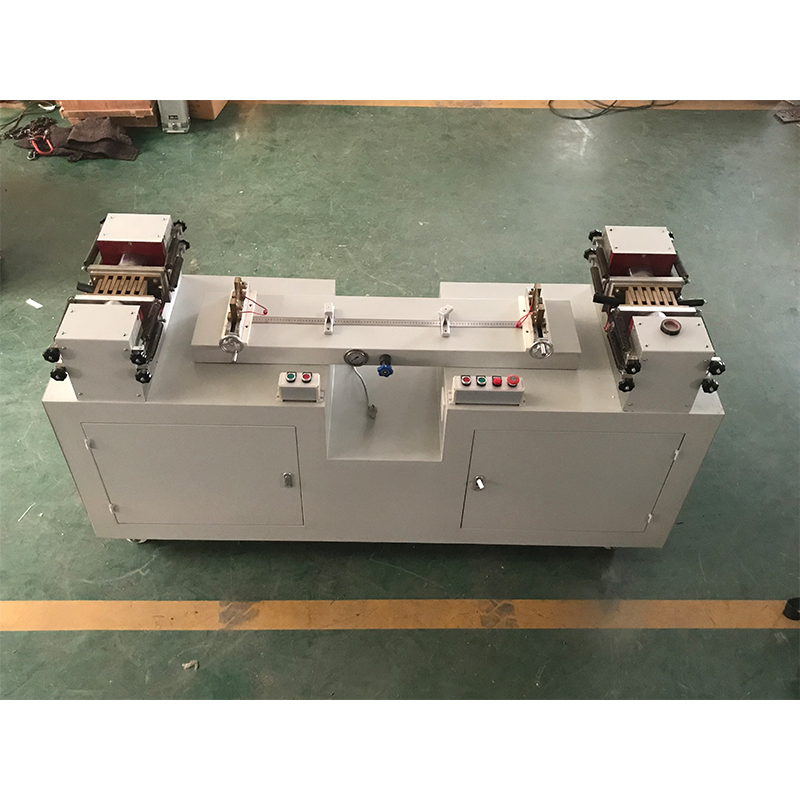

Custom Tensile Testing Machine for Measuring Break Strength Effectively and Accurately

Custom Tensile Tester for Break Strength Ensuring Quality and Reliability

In industries where materials are subjected to stress, the measurement of their tensile strength is crucial. Tensile testing is a fundamental procedure in quality assurance for a wide array of materials, including metals, plastics, and textiles. A custom tensile tester designed specifically for measuring break strength can provide organizations with the capability to assess the mechanical properties of their materials accurately.

A tensile tester operates by pulling a material sample until it breaks, measuring the amount of force applied against the elongation of the sample. This data helps engineers and quality control teams to understand how a material will behave under various loads, thus allowing for the selection of appropriate materials for specific applications. By opting for a custom tensile tester, companies can tailor the equipment to meet their unique testing requirements and specifications.

One of the primary advantages of custom tensile testers is their adaptability. Different materials have varying characteristics that may require specific testing protocols. For example, softer materials like elastomers and plastics might need different settings than harder materials like steel and composites. A custom solution can accommodate these differences effectively. This ensures that the results obtained are relevant and applicable to the specific materials being tested, leading to more reliable product development and quality control.

The design of a custom tensile tester can also incorporate various features and functionalities that enhance its utility. For instance, the integration of advanced sensors and digital data acquisition systems can provide precise measurements and real-time monitoring of the tensile testing process. This technology allows for the collection of extensive data, which can be invaluable for research and development purposes. Moreover, the ability to connect the tensile tester to other systems ensures that data can be analyzed and stored efficiently, streamlining the overall testing process.

custom tensile tester for break strength

Another critical aspect of custom tensile testers is the consideration of regulatory standards. Different industries may have specific requirements for material testing based on safety regulations or quality standards. A custom tensile tester can be designed to comply with these norms, thus ensuring that all tests performed provide valid and trustworthy results. This compliance not only enhances the credibility of the testing process but also helps organizations avoid potential legal and financial implications of using substandard materials.

Additionally, the operator's comfort and safety should never be overlooked in the design of such testing equipment. Custom tensile testers can be equipped with user-friendly interfaces, safety features, and ergonomic designs to facilitate ease of operation and minimize the risk of accidents during testing. When operators are comfortable and feel secure, they are more likely to produce accurate and consistent results.

The investment in a custom tensile tester can lead to significant long-term benefits for manufacturers and researchers. By having equipment that specifically meets their testing needs, organizations can improve the development cycle of new products, ensure the quality of existing materials, and ultimately enhance customer satisfaction. Furthermore, reliable testing can contribute to reducing material waste and optimizing resource utilization, streamlining production processes.

In conclusion, a custom tensile tester for measuring break strength is an essential tool for industries that rely on material performance. Its adaptability, compliance with standards, potential for advanced features, and focus on operator safety make it a worthwhile investment. By ensuring that materials meet the necessary quality and performance criteria, businesses can safeguard their reputation and foster innovation in their products.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy