Reliable Suppliers for High-Quality Cable Burning Test Machines Suitable for Various Industries

Choosing the Right Cable Burning Test Machine Supplier

In the realm of electrical engineering and safety testing, the importance of cable burning test machines cannot be overstated. These machines are designed to assess the flame resistance of various types of cables, ensuring they meet stringent safety standards and regulations. With a plethora of suppliers in the market, selecting the right cable burning test machine supplier is essential for manufacturers, safety organizations, and laboratories aiming to maintain high safety standards.

Understanding Cable Burning Tests

Cable burning tests evaluate how cables respond to fire conditions, which is critical for ensuring electrical systems remain safe during malfunction or emergencies. These tests generally simulate real-life fire scenarios by subjecting cables to flame sources under controlled conditions. The outcomes help determine the risks associated with burning cables, including the release of toxic gases and the potential for fire spread. Therefore, the reliability of these machines is paramount.

Key Factors to Consider

1. Quality and Compliance One of the foremost concerns when selecting a supplier is the quality of the test machines. Ensure that the equipment meets international testing standards such as IEC, UL, and ASTM. This compliance guarantees that the testing results are recognized globally, which is vital for manufacturers looking to export their products.

2. Technology and Features Modern cable burning test machines come equipped with advanced technology, including automation, real-time data logging, and smoke density measuring capabilities. When evaluating suppliers, consider whether they offer the latest technology that enhances testing accuracy and efficiency. Features such as programmable test sequences and user-friendly interfaces can significantly improve operational productivity.

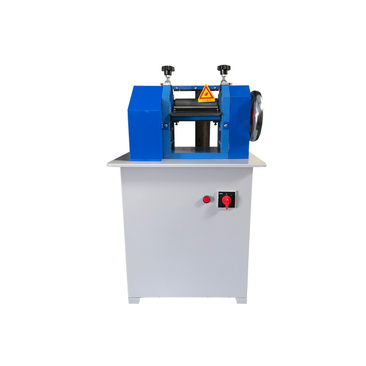

cable burning test machine supplier

3. Customization Options Different industries may have unique requirements when it comes to cable burning tests. A flexible supplier that can provide customized solutions tailored to specific testing needs can be a significant advantage. This customization can range from modifications in machine design to the integration of additional testing parameters.

4. After-Sales Support The journey doesn’t end once you purchase the machine. Reliable after-sales support is crucial for continuous operation and maintenance. Check whether the supplier offers training for your personnel, readily available spare parts, comprehensive maintenance services, and technical support. A supplier with a strong customer service orientation can help prevent lengthy downtimes and facilitate smoother operations.

5. Cost and Value While cost is an important aspect to consider, it should not be the sole deciding factor. Evaluate the value proposition offered by the supplier. A lower upfront cost might be enticing, but if the machine is not reliable or lacks adequate support, it could lead to higher long-term expenses. Look for suppliers that strike a balance between affordability and quality.

6. Reputation and Experience Research the reputation of the supplier in the industry. Suppliers with a proven track record, positive customer reviews, and extensive experience in manufacturing cable burning test machines are often a safer choice. You might also want to ask for case studies or references from previous customers to gauge their satisfaction.

Conclusion

In conclusion, selecting the right cable burning test machine supplier is a critical decision that can have far-reaching implications for safety and compliance in your operations. By carefully evaluating the quality, technology, customization options, after-sales support, cost, and reputation of potential suppliers, you can make an informed choice that meets your specific testing needs. Remember, investing in the right equipment and supplier not only ensures the safety of your products but also enhances your brand's credibility in the competitive market.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy