Top Manufacturers of Cable Sheath Cutting Machines for Efficient Wire Processing Solutions

The Rise of Cable Sheath Cut Machine Companies Meeting Industry Demands

In today’s fast-paced industrial landscape, efficiency and precision are paramount, particularly in sectors that deal with cable manufacturing and processing. As the demand for high-quality cables grows, so does the need for specialized machinery, including cable sheath cut machines. These machines play an essential role in the preparation of cables for various applications, ensuring that they are ready for installation and use. As a result, companies that specialize in manufacturing cable sheath cut machines are becoming increasingly vital players in the industry.

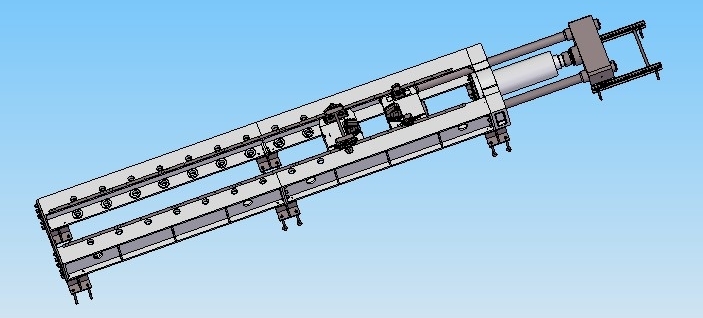

Cable sheath cut machines are designed to cut the outer insulation or sheath of electrical cables to desired lengths and diameters. This process is crucial, as it allows for easier connectivity and assembly of cables, which are commonly used in telecommunications, power distribution, and various electronics. The machines are typically equipped with advanced technology that enables precise measurements and cuts, minimizing waste and maximizing efficiency.

Several companies have emerged as leaders in this niche market, each offering unique features and innovations. These manufacturers have recognized the need for versatility in their machines, accommodating different types of cables, including coaxial, fiber optic, and multi-conductor varieties. Many of these companies also provide customizable solutions, allowing clients to adjust the machine specifications based on their specific requirements.

One of the key factors driving the growth of cable sheath cut machine companies is the increasing complexity of cable designs. As technology advances, cables are often used in more intricate applications, necessitating precise cutting and handling. Furthermore, the rise of renewable energy sources and electric vehicles has created a surge in demand for high-quality cables, pushing manufacturers to enhance their production capabilities.

cable sheath cut machine companies

Automation is another significant trend impacting the industry. Modern cable sheath cut machines are often automated, allowing them to operate with minimal human intervention. This not only enhances production rates but also significantly reduces the likelihood of errors during the cutting process. Companies that have adopted automation have seen substantial improvements in efficiency, with some reporting a reduction in operational costs and increased output.

In addition to innovation and automation, sustainability has become a focal point for many cable sheath cut machine manufacturers. As industries worldwide strive to reduce their environmental footprint, these companies are looking for ways to make their operations more sustainable. This includes utilizing eco-friendly materials in machine construction, implementing energy-efficient technologies, and designing machines that produce less waste during the cable cutting process.

The global market for cable sheath cut machines is poised for significant growth in the coming years. As more industries recognize the benefits of investing in high-quality cutting machines, cable sheath cut machine companies are likely to expand their reach. Additionally, as emerging markets develop their infrastructure, there will be an increased demand for robust cable solutions, further bolstering the need for advanced cutting machinery.

Collaboration and partnerships are also shaping the future of cable sheath cut machine companies. Manufacturers are increasingly teaming up with research institutions and technology firms to develop innovative solutions that meet the demands of the evolving market. These collaborations can lead to groundbreaking advances in machine design and efficiency, keeping companies at the forefront of the industry.

In conclusion, the rise of cable sheath cut machine companies is indicative of larger trends within the manufacturing and technological sectors. As industries continue to evolve and demand higher precision and efficiency, these companies will play a crucial role in shaping the future of cable processing. With a focus on innovation, automation, sustainability, and collaboration, cable sheath cut machine manufacturers are well-positioned to meet the increasing demands of the global market.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy