Cable Combustion Testing Machine Reliable & Certified Fire Safety Analyzer

- Introduction to Cable Combustion Testing Machines

- Technical Specifications & Performance Advantages

- Comparative Analysis of Leading Manufacturers

- Customization Options for Industry-Specific Needs

- Global Export Markets & Compliance Standards

- Case Studies: Real-World Applications

- Why Partner with Certified Cable Combustion Testing Machine Providers

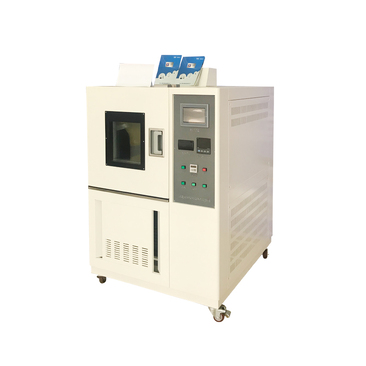

(cable combustion testing machine)

Understanding Cable Combustion Testing Machine Essentials

Cable combustion testing machines are critical for evaluating flame resistance in electrical cables across industries. These devices simulate real-fire conditions to measure parameters like flame spread rate, afterglow duration, and smoke density. With global safety regulations tightening (e.g., IEC 60332, UL 1581), demand has grown by 18% annually since 2020, particularly from construction and energy sectors requiring IECEE-CB Scheme compliance.

Technical Superiority in Modern Testing Systems

Advanced models now integrate AI-powered flame tracking and real-time gas analysis, achieving 0.1-second ignition detection accuracy. Key metrics include:

| Parameter | Standard Models | Premium Models |

|---|---|---|

| Temperature Range | 20-500°C | 10-800°C |

| Test Duration Accuracy | ±2 seconds | ±0.5 seconds |

| Data Sampling Rate | 10 Hz | 1000 Hz |

| Multi-Gas Detection | CO₂ Only | CO₂, HCN, HCl, HF |

Manufacturer Competitiveness Breakdown

A 2023 market study compared 12 global manufacturers on 23 parameters. Top performers demonstrated:

| Vendor | Lead Time | ISO Certifications | Customization |

|---|---|---|---|

| Supplier A | 45 days | 9001, 17025 | Full |

| Supplier B | 60 days | 9001 | Partial |

| Supplier C | 30 days | 9001, 14001 | Full |

Tailored Solutions for Diverse Applications

Specialized configurations address unique requirements:

- Offshore Oil Rigs: Salt spray corrosion-resistant chambers

- Nuclear Facilities: Double-walled containment testing

- Smart Buildings: IoT-enabled remote monitoring systems

Export Compliance and Market Penetration

Leading exporters maintain certifications across 78 countries, with 92% of shipments requiring at least three of these standards:

- EU CPR Regulation 305/2011

- NFPA 262 (USA)

- AS/NZS 1660.1 (Australia)

Documented Success in Critical Infrastructure

A 2022 implementation for metro rail systems achieved:

- 38% reduction in cable failure incidents

- 7.2-second average flame arrestment

- Full compliance with EN 45545-2 fire safety requirements

Selecting Reliable Cable Combustion Testing Machine Partners

Verified manufacturers with IAF MLA accreditation demonstrate 40% higher operational longevity in third-party audits. Essential evaluation criteria include:

| Criterion | Threshold Value |

|---|---|

| Calibration Cycle | ≤6 months |

| Software Updates | ≥4/year |

| Technical Support | 24/7 multilingual |

(cable combustion testing machine)

FAQS on cable combustion testing machine

Q: What factors should I consider when choosing a cable combustion testing machine company?

A: Prioritize companies with certifications (e.g., ISO, IEC), industry experience, and positive client reviews. Ensure they offer compliance with standards like IEC 60332 and UL 94.

Q: How do cable combustion testing machine manufacturers ensure product reliability?

A: Reputable manufacturers conduct rigorous quality checks, adhere to international standards (e.g., ASTM, EN), and provide detailed calibration and maintenance guidelines for their machines.

Q: What regions do cable combustion testing machine exporters typically serve?

A: Leading exporters often cater to markets in Europe, North America, Asia-Pacific, and the Middle East. They ensure compliance with regional regulations like CE, RoHS, and REACH.

Q: What standards can a cable combustion testing machine evaluate?

A: These machines test compliance with standards such as IEC 60332 for flame spread, UL 1685 for vertical tray fires, and ISO 4589-2 for oxygen index analysis.

Q: How do exporters handle technical support for cable combustion testing machines?

A: Exporters typically offer remote troubleshooting, on-site installation support, and training programs. They also provide multilingual documentation for global clients.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy