cable aging oven exporter

The Importance of Cable Aging Ovens in the Electrical Industry

In the modern electrical industry, the reliability of cable insulation is paramount. As infrastructure projects grow in complexity and scale, the need for high-quality, durable electrical cables has never been more essential. One of the key processes that ensure the longevity and reliability of these cables is aging tests, conducted using specialized equipment known as cable aging ovens. This article will explore the significance of cable aging ovens in the industry, their operational principles, and the qualifications necessary for exporters of cable aging ovens.

Understanding Cable Aging Ovens

Cable aging ovens are specialized devices designed to test the long-term integrity of electrical cables and their insulation materials. These ovens simulate years of environmental exposure in a significantly reduced time frame, enabling manufacturers to assess the performance and reliability of their products efficiently.

The aging process usually involves testing cables at elevated temperatures, thereby accelerating the aging process. By exposing cables to heat, humidity, and other stress factors, manufacturers can predict their lifespan and performance under real-world conditions. This helps manufacturers identify potential weaknesses in their products before they reach the consumer, ensuring that only the best quality cables are used in critical applications.

The Operational Principles

Cable aging ovens operate under strict conditions, including precise temperature controls, humidity management, and airflow mechanisms. The temperature inside these ovens can be adjusted according to the specific requirements of the testing standards, often ranging from 100°C to 180°C.

A key feature of a sophisticated aging oven is the ability to control atmospheric conditions, which can influence the aging process. For instance, the introduction of moisture can simulate a humid environment, while dry conditions can be replicated to study the effects of prolonged heat exposure without humidity.

Additionally, modern cable aging ovens are equipped with advanced monitoring systems that provide real-time data on temperature and humidity levels. This is crucial for maintaining the integrity of the testing process and ensuring compliance with industry standards such as IEC and ASTM.

cable aging oven exporter

The Role of Exporters

With the increasing demand for high-quality cable aging ovens, exporters play a significant role in the distribution of these essential appliances worldwide. An exporter must not only ensure the quality of their products but also comply with international standards and regulations. This includes obtaining relevant certifications for safety and performance, as well as adhering to trade regulations.

Exporters should also be aware of the specific needs and requirements of their target markets. Different regions may have varying standards for electrical cables, and understanding these nuances can help exporters tailor their products accordingly. Building strong relationships with manufacturers and distributors can also facilitate smoother operations and enhance market reach.

Emerging Trends and Innovations

The cable aging oven market is witnessing significant technological advancements aimed at increasing efficiency and accuracy. For example, the integration of IoT (Internet of Things) technology allows operators to monitor aging processes remotely, thus improving overall efficiency. Moreover, automated systems reduce human error and ensure a consistent testing environment.

As environmental concerns rise, manufacturers are also focusing on developing energy-efficient equipment, minimizing their carbon footprint during the aging process. These innovations not only address regulatory pressures but also appeal to eco-conscious clients.

Conclusion

In conclusion, cable aging ovens are indispensable tools in the electrical industry, ensuring the reliability and longevity of cable products. As demand for high-quality electrical cables increases, the role of exporters in the supply chain becomes increasingly crucial. By understanding market needs, adhering to international standards, and embracing technological advancements, exporters can contribute significantly to the growth and development of the electrical industry.

As we move towards a future with more demanding electrical applications, the importance of testing and quality assurance will only grow. By investing in reliable cable aging ovens and fostering strong international trading relationships, the industry can ensure that the integrity of electrical cables not only meets but exceeds expectations.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

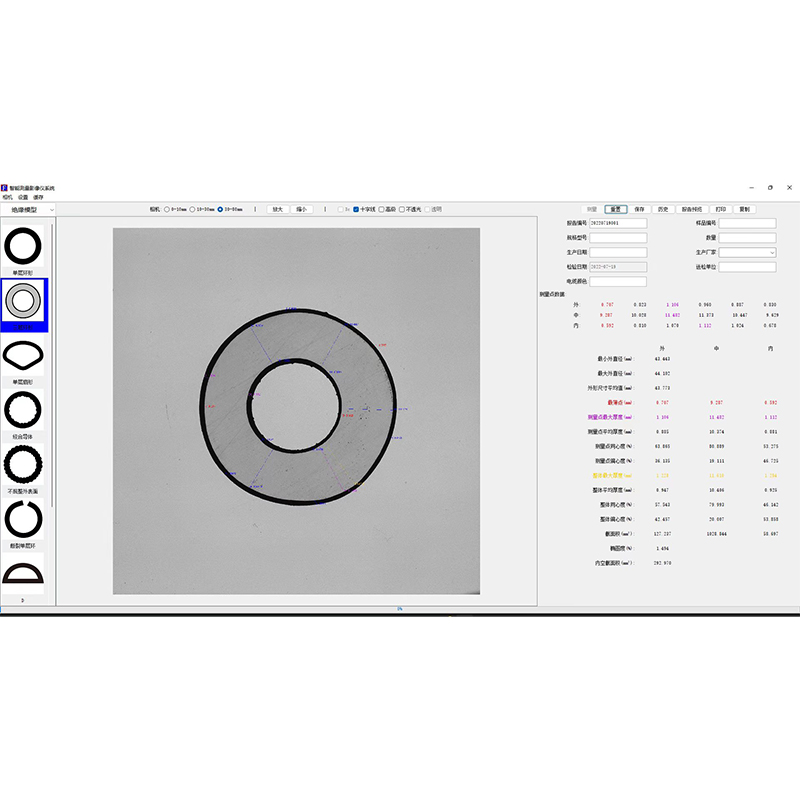

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy