cable cutting machine factories

The Rise of Cable Cutting Machine Factories Revolutionizing the Wire and Cable Industry

In today's world, where efficiency and precision are paramount in manufacturing, cable cutting machine factories are making significant strides. These factories are dedicated to producing specialized machines that automate the cable cutting process, a crucial aspect of various industries including telecommunications, automotive, and electronics. As technology advances and the demand for high-quality, custom-cut cables increases, the role of cable cutting machines becomes more prominent.

A Gateway to Precision

Cable cutting machines are designed to cater to specific requirements in cable manufacturing. They offer precise cutting lengths, can handle various cable types—ranging from copper and aluminum to other material compositions—and ensure minimal waste. The need for precision in the wire and cable industry cannot be overstated. As products become smaller and more complex, manufacturers rely on automated solutions to ensure that cables are cut accurately to fit into intricate designs.

The automation of this process not only enhances precision but also improves efficiency. Manual cutting, while still prevalent in some smaller operations, is often slower and more prone to human error. In contrast, automated cable cutting machines can operate continuously, significantly increasing production rates. This is particularly beneficial for industries with high-volume cable needs, where even the slightest deviation in cutting length can lead to complications down the line.

Cost-Effectiveness and Waste Reduction

Investing in cable cutting machines can lead to significant cost savings over time. Although the initial investment may be substantial, the long-term benefits make these machines economically viable. Automation reduces labor costs, as fewer workers are needed to manage the cutting process. Additionally, the precision of these machines leads to less material waste, as the likelihood of miscutting is minimized.

As manufacturers aim to embrace sustainability, the reduced waste produced by cable cutting machines also contributes to more environmentally friendly practices. By optimizing material usage, factories can decrease their carbon footprint and promote a more sustainable manufacturing process.

cable cutting machine factories

Technological Innovations

Recent advancements in technology have further enhanced the capabilities of cable cutting machines. The integration of smart technologies, such as IoT and AI, allows for real-time monitoring of the cutting process. Manufacturers can analyze data to optimize settings for different cable types, ensuring consistent quality while minimizing downtime. This data-driven approach empowers factories to adapt quickly to changing demands and maintain high standards.

Moreover, many modern cable cutting machines are designed to be user-friendly, with intuitive interfaces that allow operators to easily program cutting parameters. This adaptability is crucial in the fast-paced manufacturing environment, where quick adjustments can lead to significant time and cost savings.

Market Growth and Future Prospects

The global market for cable cutting machines is poised for growth. As industries expand and the demand for high-quality cables rises, especially with the increasing adoption of electric vehicles and renewable energy technologies, the need for efficient cable cutting solutions will continue to escalate. Furthermore, emerging markets are witnessing a surge in infrastructure development, which will likely boost the demand for cable cutting machines.

Conclusion

Cable cutting machine factories play an integral role in transforming the wire and cable manufacturing landscape. By embracing automation, advancing technology, and focusing on precision and efficiency, these factories contribute to the overall improvement of production processes in various industries. As the market evolves and demands continue to grow, the future of cable cutting machines looks promising. Manufacturers that invest in these innovative solutions will not only enhance their operational efficiency but will also position themselves competitively in the ever-changing global marketplace. The journey of these machines has just begun, and their potential impact on the industry is boundless.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

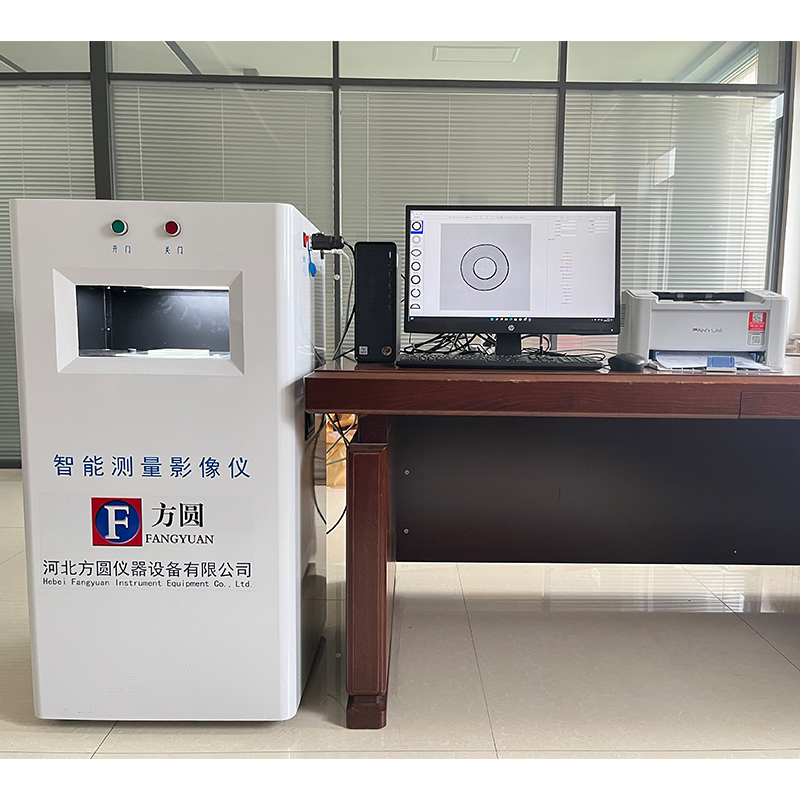

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy