custom cable measurement machine

Custom Cable Measurement Machine Revolutionizing Cable Production

In the ever-evolving world of technology and manufacturing, precision and efficiency are paramount. One of the critical components in various industries, such as telecommunications, automotive, and electronics, is cable. Whether it's for data transmission or electrical connectivity, the demand for high-quality cables is increasing. To meet this demand, custom cable measurement machines have emerged as a game-changer in the production process.

Custom cable measurement machines are specifically designed to measure and inspect cables with utmost accuracy. These machines utilize advanced technologies, such as laser measurement systems and high-resolution cameras, to ensure that every aspect of the cable, including length, diameter, and insulation thickness, conforms to the specified standards. This meticulous attention to detail not only enhances the quality of the final product but also minimizes the waste of materials and resources.

One of the significant advantages of using custom cable measurement machines is their ability to streamline the production process. Traditional measurement methods often involve manual inspection, which can be time-consuming and prone to human error. In contrast, automated measurement systems can quickly and accurately assess multiple cables in real-time, significantly reducing the time required for quality control. This efficiency allows manufacturers to increase their production rates and meet tight deadlines without compromising on quality.

custom cable measurement machine

Furthermore, custom cable measurement machines can be tailored to meet specific requirements of different industries. For instance, in the aerospace sector, cables must adhere to stringent safety standards and performance metrics. A customized measurement system can be engineered to perform specialized tests, ensuring that the cables not only meet regulatory compliance but also function optimally under extreme conditions.

Another noteworthy benefit is the data acquisition capabilities of modern measurement machines. These machines can collect vast amounts of data during the measurement process, providing manufacturers with valuable insights into their production practices. By analyzing this data, businesses can identify trends, detect anomalies, and implement process improvements, ultimately leading to better product quality and reduced costs.

In conclusion, custom cable measurement machines represent a significant advancement in cable manufacturing. By combining precision measurement, automation, and data analytics, these machines enhance production efficiency and ensure superior quality. As industries continue to evolve and demand for high-quality cables rises, investing in such technology will be crucial for manufacturers looking to stay competitive in the marketplace. The future of cable production is not just about making connections; it’s about making them better, faster, and more reliable.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

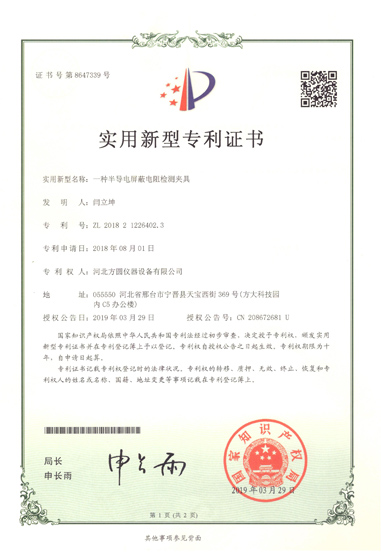

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy