Ιαν . 29, 2025 06:13

Back to list

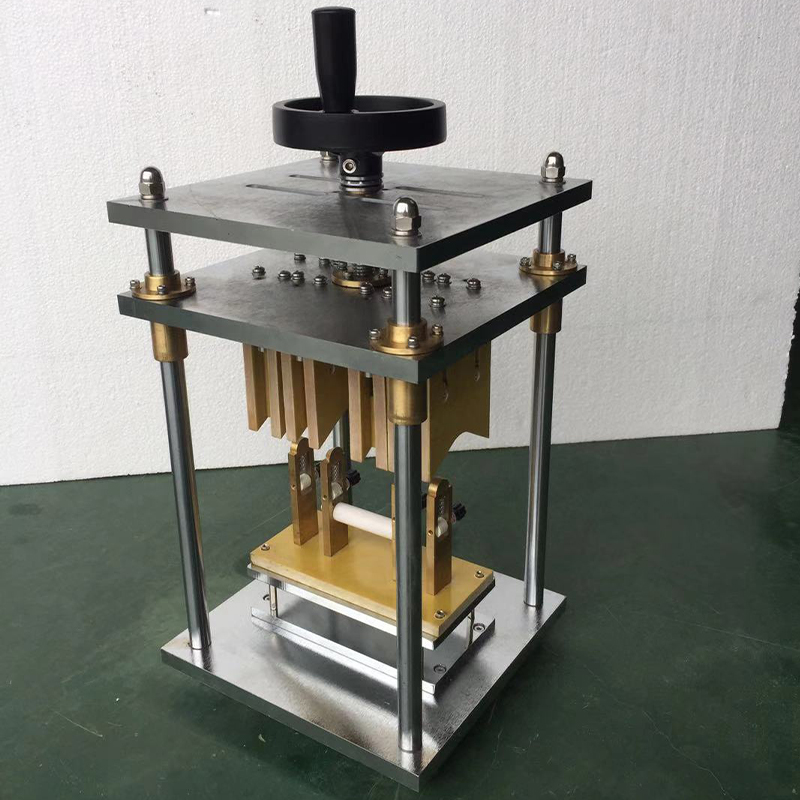

Wire and Cable Smoke Density Test Machine

In the world of advanced electronics and material science, precision in measuring electrical resistivity is crucial for quality control and system efficiency. Custom resistivity testers have emerged as indispensable tools, providing tailored solutions to meet specific industry requirements. These devices serve as the backbone of accurate resistivity measurements, thus ensuring the longevity and performance of electronic components across sectors such as semiconductor manufacturing, materials development, and energy production.

Reliability, as an essential attribute of custom resistivity testers, cannot be overstated. These testers are built to function accurately over extended periods, often in harsh industrial environments. The trustworthiness of a device is established through its ability to maintain consistent performance over time. By employing high-quality components and incorporating robust design principles, manufacturers ensure that these devices can withstand the rigors of continuous use, thereby protecting investment and minimizing operational downtime. Moreover, custom resistivity testers often feature user-friendly interfaces designed to facilitate ease of operation and interpretation of results. This user-centric design is crucial for efficient workflow integration, allowing technicians and engineers to quickly obtain and analyze data without the steep learning curve associated with complex machinery. The simplification of data acquisition and analysis not only boosts productivity but also enhances the overall user experience—a key factor in the successful adoption of any technological solution. In terms of expertise, custom resistivity testers offer specialized functionalities that cater to sophisticated measurement needs. Expertise-driven enhancements might include specialized software for data analysis, automated reporting capabilities, and integration with existing laboratory information management systems (LIMS). Such features enable users not only to gather data efficiently but also to process and interpret findings in a manner that is aligned with institutional or industrial objectives. Ultimately, the decision to invest in a custom resistivity tester is one rooted in the understanding of the profound impact precise resistivity measurement can have on product development and operational efficiency. These devices embody a level of proficiency and reliability that generic options simply cannot match, thus enabling industries to push the boundaries of innovation while maintaining high standards of quality. For any organization that demands superiority in resistivity measurement, a custom resistivity tester is not just a tool, but a pivotal component in their technological arsenal—helping transform intricate challenges into groundbreaking achievements.

Reliability, as an essential attribute of custom resistivity testers, cannot be overstated. These testers are built to function accurately over extended periods, often in harsh industrial environments. The trustworthiness of a device is established through its ability to maintain consistent performance over time. By employing high-quality components and incorporating robust design principles, manufacturers ensure that these devices can withstand the rigors of continuous use, thereby protecting investment and minimizing operational downtime. Moreover, custom resistivity testers often feature user-friendly interfaces designed to facilitate ease of operation and interpretation of results. This user-centric design is crucial for efficient workflow integration, allowing technicians and engineers to quickly obtain and analyze data without the steep learning curve associated with complex machinery. The simplification of data acquisition and analysis not only boosts productivity but also enhances the overall user experience—a key factor in the successful adoption of any technological solution. In terms of expertise, custom resistivity testers offer specialized functionalities that cater to sophisticated measurement needs. Expertise-driven enhancements might include specialized software for data analysis, automated reporting capabilities, and integration with existing laboratory information management systems (LIMS). Such features enable users not only to gather data efficiently but also to process and interpret findings in a manner that is aligned with institutional or industrial objectives. Ultimately, the decision to invest in a custom resistivity tester is one rooted in the understanding of the profound impact precise resistivity measurement can have on product development and operational efficiency. These devices embody a level of proficiency and reliability that generic options simply cannot match, thus enabling industries to push the boundaries of innovation while maintaining high standards of quality. For any organization that demands superiority in resistivity measurement, a custom resistivity tester is not just a tool, but a pivotal component in their technological arsenal—helping transform intricate challenges into groundbreaking achievements.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy