Power Frequency Spark Tester Production and Supplier Insights in Testing Industry

The Importance of Power Frequency Spark Testers in Electrical Safety

In the world of electrical engineering, ensuring the safety and reliability of high voltage equipment is paramount. One of the most effective tools in this regard is the power frequency spark tester. These devices play a crucial role in verifying insulation quality, preventing electrical failures, and ultimately, safeguarding both human lives and expensive equipment. This article delves into the significance of power frequency spark testers, their working principles, and the manufacturers leading the market today.

Understanding Power Frequency Spark Testing

Power frequency spark testing, also known as dielectric testing, involves subjecting electrical insulation to high-frequency voltage to assess its integrity. The primary purpose of this testing is to identify any weaknesses or faults in the insulation that could lead to dangerous electrical discharges or failures. By applying a voltage that is typically several times higher than the normal operating voltage, the tester can simulate conditions that may occur during real-world operations.

The process can detect pinholes, voids, and other imperfections within the insulation material which might not be visible to the naked eye. Its effectiveness lies in its ability to simulate high-stress conditions, allowing manufacturers and engineers to ensure that their products can withstand actual operational environments.

Key Applications of Power Frequency Spark Testers

Power frequency spark testers are utilized across various industries that handle high voltage equipment, including

1. Manufacturing Plants In factories producing motors, transformers, and cables, ensuring insulation integrity is critical. Regular testing minimizes downtime and avoids costly failures.

2. Utilities Power generation and distribution companies use spark testers to maintain the reliability of their transmission lines and substations. This proactive approach helps prevent power outages and ensures safety.

3. Transportation In sectors like railways and aviation, electrical systems must meet stringent safety standards. Spark testers play an essential role in certifying the electrical systems used in trains and aircraft.

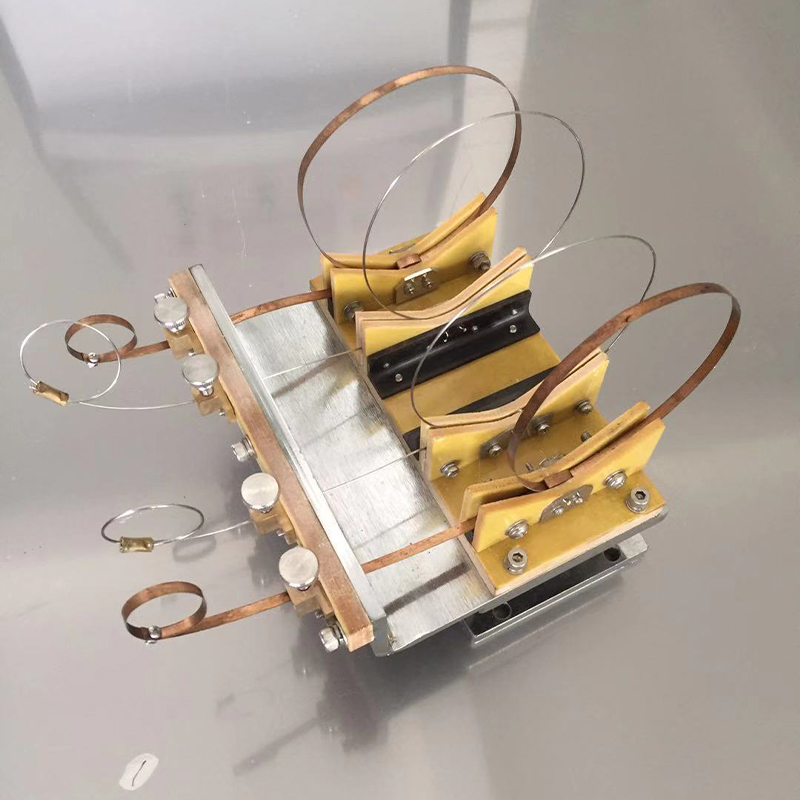

power frequency spark tester manufacturer

4. Renewable Energy With the rise of solar and wind energy systems, spark testing ensures that the insulation used in inverters and electrical components can handle high voltages over time.

Choosing a Trusted Manufacturer

When it comes to selecting a power frequency spark tester, the manufacturer significantly influences performance, reliability, and accuracy. Leading manufacturers are known for their innovation, commitment to quality, and adherence to industry standards. Some of the top companies in the field include

1. Megger Renowned for their advanced electrical testing equipment, Megger offers a range of power frequency testers that are user-friendly and designed for accuracy.

2. Fluke Corporation Known for precision instruments, Fluke’s spark testers are equipped with cutting-edge technology that helps in obtaining reliable insulation measurements.

3. AEMC Instruments AEMC provides robust testing solutions that combine functionality with durability, making them a popular choice among professionals.

4. Chroma ATE Chroma's testers focus on providing versatile solutions for various applications, ensuring that their clients can meet different testing requirements with one device.

Conclusion

The role of power frequency spark testers in electrical safety cannot be overstated. These devices are vital in ensuring the integrity of insulation in high voltage equipment, thereby preventing potential hazards. As demand for reliable electrical systems continues to rise, so does the importance of quality testing equipment. By partnering with reputable manufacturers, industries can enhance their safety protocols, improve operational efficiency, and mitigate risks associated with electrical failures. Regular testing not only ensures compliance with safety standards but also instills confidence in the reliability of electrical infrastructure, ultimately contributing to a safer environment for both workers and the general public.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy