Leading Manufacturers of High-Precision Tensile Test Equipment for Material Testing Solutions

Understanding Tensile Testers A Comprehensive Overview of Manufacturers and Their Impact on Material Testing

In the realm of materials science and engineering, the tensile test is a fundamental procedure that determines the mechanical properties of materials, particularly their strength, ductility, and tensile behavior. The machinery crucial to this process is known as tensile testers or tensile testing machines. As industries evolve and demand for high-quality materials increases, the role of tensile testers and their manufacturers has become increasingly significant.

What is a Tensile Tester?

A tensile tester is a specialized apparatus designed to apply a controlled tensile load to a material specimen until it deforms or fractures. This process yields essential data regarding various aspects of the material, such as ultimate tensile strength (UTS), yield strength, elongation, and reduction of area. These parameters help engineers and researchers select appropriate materials for various applications, ensuring safety and reliability.

The Importance of Quality in Tensile Testing Equipment

The accuracy and reliability of tensile testing are heavily reliant on the quality of the testing equipment. A well-manufactured tensile tester provides consistent and repeatable results, which are crucial for standards compliance and quality assurance. Hence, finding a reputable tensile tester manufacturer is a priority for many businesses involved in material testing.

Key Features to Look for in Tensile Testers

1. Load Capacity Tensile testers come in various load capacities, making it essential to select a machine that suits the specific testing requirements of the materials in question. Manufacturers often provide machines with capacities ranging from a few grams to several hundred kilonewtons.

2. Precision and Accuracy The capability to precisely measure the applied load and the corresponding elongation of the specimen is critical. Advanced tensile testers incorporate high-resolution load cells and extensometers to enhance measurement accuracy.

3. User-Friendly Software Modern tensile testers are equipped with sophisticated software that aids in real-time data collection, analysis, and reporting. This software should be intuitive and capable of generating detailed reports as per industry standards.

4. Versatility The best tensile testers can accommodate a variety of materials including metals, plastics, and textiles. Manufacturers that offer modular testing solutions allow users to adapt their machines for different testing needs.

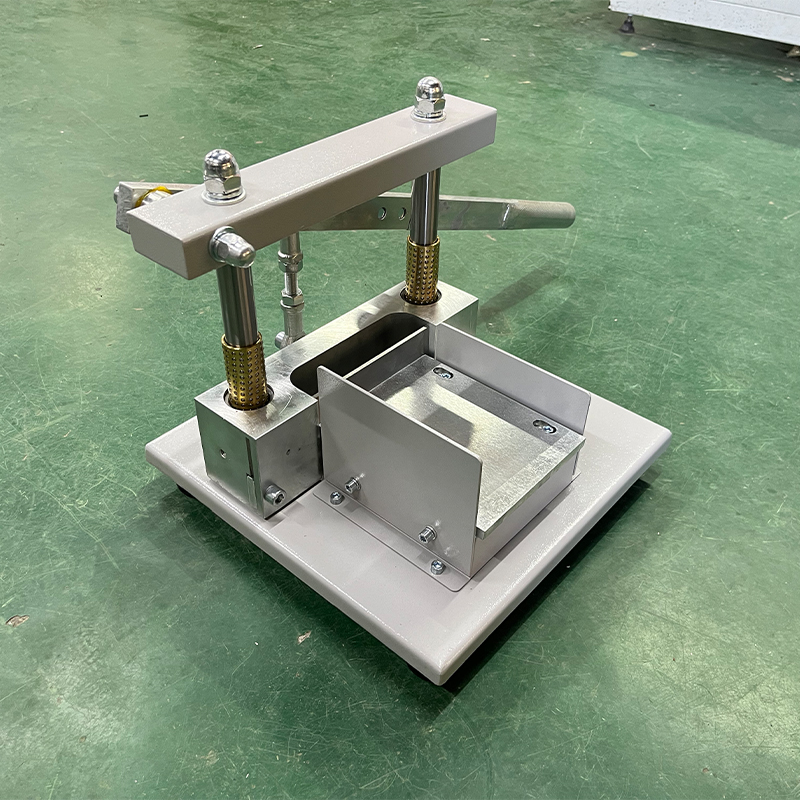

tensile testers manufacturer

5. Compliance with Standards Ensuring that the equipment meets international testing standards, like ASTM, ISO, or DIN, is vital for businesses aiming for market credibility.

Leading Manufacturers in Tensile Testing Equipment

The market for tensile testers has grown considerably, with numerous manufacturers vying for leadership. Some of the notable manufacturers include

- BSD Testing Renowned for their durable and reliable tensile testing machines, BSD offers a range of customizable solutions that cater to various industries including automotive and aerospace.

- Instron A pioneer in materials testing, Instron is recognized for its high-performance tensile testers, which are widely used in universities and research institutions.

- Tinius Olsen Known for their robust machines, Tinius Olsen has a strong reputation for quality and precision in the tensile testing sector, catering to various sectors from rubber to metals.

- MTS Systems This manufacturer specializes in advanced testing solutions, including sophisticated tensile testers that are ideal for research and development applications.

Future Trends in Tensile Testing

As technology advances, tensile testers are becoming smarter. Integrating IoT (Internet of Things) technology into testing machines allows for remote monitoring, data management, and real-time analytics. Moreover, the growth of automation in manufacturing and testing processes ensures that tensile testers will play a pivotal role in quality control and assurance.

In conclusion, tensile testers are an indispensable tool in material testing, and their manufacturers are crucial players in ensuring the reliability and accuracy of testing results. By focusing on quality, precision, and adherence to industry standards, manufacturers contribute significantly to the safety and effectiveness of materials used across various applications. As industries continue to evolve, so too will the capabilities and technologies associated with tensile testing equipment, shaping the future of material science and engineering.

-

Reliable Performance Testing with Advanced Aging Chamber Solutions

NewsAug.23,2025

-

Advancing Precision with Profile Projector Technology

NewsAug.23,2025

-

UV-LED Ultraviolet Crosslinking Technology: Innovation and Prospects

NewsAug.23,2025

-

Ensuring Safety and Compliance

NewsAug.23,2025

-

Electrical Properties Testing in Modern Applications

NewsAug.23,2025

-

Universal Tensile Testing Machine Applications in Modern Electrical and Material Testing

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy