uv crosslinking equipment factory

The Evolution and Importance of UV Crosslinking Equipment in Modern Manufacturing

In recent years, the manufacturing industry has witnessed significant advancements, particularly in the realm of UV crosslinking technology. This innovative process has transformed the way various materials are bonded and cured, offering a range of benefits that are crucial for a multitude of applications. At the heart of this technology lies UV crosslinking equipment, which is manufactured by specialized factories dedicated to creating high-quality machinery designed to enhance production processes.

Understanding UV Crosslinking

UV crosslinking refers to a photochemical reaction where ultraviolet light is used to create bonds between polymer chains, resulting in a three-dimensional network that enhances the properties of the material. This process is particularly valuable in industries such as automotive, electronics, and coatings, where durability, chemical resistance, and quick curing times are essential.

The basic mechanics of UV crosslinking involve the application of a UV-sensitive resin that contains photoinitiators. These compounds absorb UV light and initiate the polymerization process, leading to crosslinking. The result is a material that exhibits improved mechanical strength, thermal stability, and resistance to environmental factors.

The Role of Factories in UV Crosslinking Equipment Production

The production of UV crosslinking equipment is a meticulous process. Factories dedicated to this technology employ advanced engineering techniques to design, manufacture, and assemble machines that cater to the specific needs of various industries. These facilities are equipped with state-of-the-art technologies, including precision engineering and automation systems, to ensure high-quality output and efficiency.

Moreover, manufacturers of UV crosslinking equipment must stay abreast of technological advancements and industry standards. Continuous research and development play a vital role in this sector, enabling factories to innovate and improve their products. This includes the development of more efficient UV light sources, advanced control systems for better precision, and environmentally friendly materials for both equipment and resins used in the crosslinking process.

uv crosslinking equipment factory

Benefits of UV Crosslinking Equipment

1. Efficiency and Speed One of the most significant advantages of UV crosslinking equipment is the rapid curing capabilities it offers. Unlike traditional curing methods that rely on heat and can take hours or even days, UV curing can be achieved in seconds. This allows manufacturers to increase throughput and meet tight production schedules.

2. Enhanced Material Properties UV crosslinking results in superior adhesion, chemical resistance, and mechanical strength. These properties make products more durable and extend their lifespan, which is particularly important in competitive markets.

3. Reduced Waste and Energy Consumption The efficiency of UV curing translates to lower energy consumption and minimal waste. Factories can optimize their processes by using less material for production, which not only reduces costs but also minimizes environmental impact.

4. Versatility UV crosslinking equipment is adaptable and can be used with a wide range of materials, including inks, adhesives, coatings, and thermoplastics. This versatility allows manufacturers to address diverse applications and market demands.

Future Prospects

As technology continues to evolve, the future of UV crosslinking equipment looks promising. With growing awareness of environmental sustainability, manufacturers are innovating to create eco-friendly solutions. This includes developing UV curing systems that use lower energy wavelengths and bio-based resins.

In conclusion, UV crosslinking equipment plays a pivotal role in modern manufacturing processes, providing efficiency, durability, and versatility. As factories continue to innovate and improve their production techniques, the applications and benefits of UV crosslinking are likely to expand, making it an essential technology for industries across the globe. The commitment to enhancing these systems not only drives productivity but also supports a shift toward more sustainable manufacturing practices, reflecting the industry's responsiveness to both market needs and environmental challenges.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

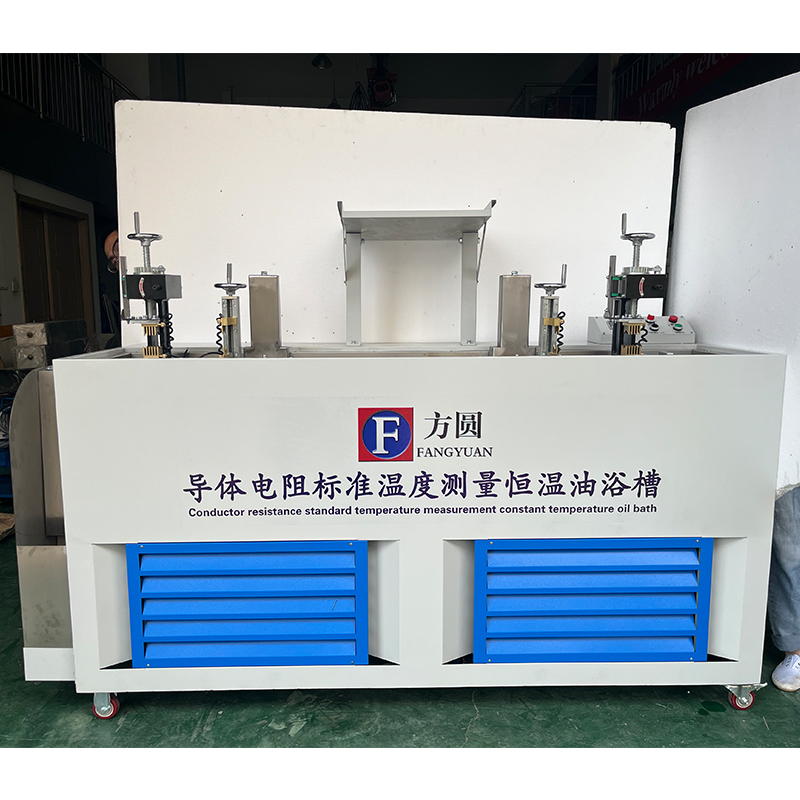

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy